Nichiei Company, Ltd.

How much do you know about polymer gears and bearings?

Polymers can provide lighter weight…lower noise…no corrosion…high temperature and LOWER COSTS compared to metals!

Nichiei Can Solve Your Power Transmission Problems so let us review your prints and provide a quote.

Call Liz at 201-513-6310 to discuss your biggest challenges.

Nichiei employs an integrated system which handles the production of prototypes of highly functional precision parts which uses engineering plastics and super-engineering plastics (e.g. PEEK, PAI, and PI) to the mass production of molds and precision injection molds.

We are able to achieve weight reduction and cost reduction in addition to higher functionality, such as slidability, and heat and wear resistance.

Nichiei employs an integrated system which handles the production of prototypes of highly functional precision parts which uses engineering plastics and super-engineering plastics (e.g. PEEK, PAI, and PI) to the mass production of molds and precision injection molds.

We are able to achieve weight reduction and cost reduction in addition to higher functionality, such as slidability, and heat and wear resistance.

In ultra-precision super-engineering plastic molds, there is a fine relationship between the refined mold manufacturing technology and the exceptional molding technology. at Nichiei, we are able to fuse these two processing technologies; thereby enabling the stable mass production of highly functional and ultra-precise parts. High performance is achieved by substitution of metallic parts.

Examples of Processed Products

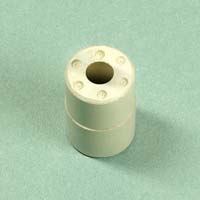

| 1. Plastic shaft bearing with a deflection tolerance for the internal and external diameter of 0.005 mm Usage: Bearing shaft for OA equipment Material: Acetal (POM) Die: 4 cavity Reason of development: New Application A customer had used a machining process in the early stage of development, and later used a wet polishing process. However, they were struggling to meet the specifications, even during this development stage. Nichiei received inquiries from them and recommended using an injection molding process. The part was made from acetal (POM), a crystalline resin that has a high post-molded shrinkage rate, something that was unacceptable to the customer. To solve this problem, we worked with the customer to produce a machine that could measure molding tolerance precisely, and observed the variation over time 1 month, 3 month, 6 month and 1 year after molding. After confirming that there was no change in dimension, mass production was started. Based upon the volumes required, Nichiei built a 4-cavity tool with a tolerance of 2u-3u, supporting the mass production of 300,000 bearing shafts per month. |

| 2. Thick-walled bearing shaft: Coaxiality tolerance of 0.01 mm Usage: Bearing shaft for OA equipment Material: Acetal (POM) Die: 1 cavity Reason of development: Replacement of a machined part to improve quality A customer had used a machining process to meet the specifications in the early stage of development. The process was time-consuming, costly and yields were low due to quality issues. Nichiei was contacted by the customer and recommended injection molding. A major concern for this part was the fact that it was thick-walled, which often leads to a surface indentation, or or "sink mark", due to material shrinkage during cooling. In fact, molding this part with a coaxial tolerance of 0.01mm was extremely challenging, but Nichiei was able to solve all the problems, producing a blemish-free part which is now in full commercial production. |

| 3. Plastic bearing shaft: Circularity of 0.002 mm; External diameter tolerance range of 0.008 mm Usage: Bearing shaft for OA equipment Material: Liquid Crystal Polymer (LCP) Die: 4 cavity Reason of development: New development (trial production) A customer was struggling to achieve tight tolerances in a molded part requiring circularity of 0.002mm and an external diameter tolerance of 0.008mm. Nichiei offered a proprietary molding methodology that is now meeting both the performance and specification requirements, resulting in a very satisfied customer. |

| 4. Insert gear of JGMA Grade 0 Usage: Gear for OA equipment Material: POM, elastomer Die: 4 cavity Reason of development: Next generation design to eliminate noise during operation A customer realized they needed a plastic gear to reduce the noise in their Office Automation equipment. Since plastic alone would not meet the high temperature requirements of the part, it was suggested that they include a metal component within the plastic gear. However, a metal/plastic insert molded gear typically does not maintain the tight co-axial tolerance required for a JGMA Grade 0 gear. The customer came to Nichiei who then developed a new (patented) molding technology to produce an insert molded gear that maintains the necessary accuracy and dimensional stability, while meeting the fitness-for-use requirements of the part. |

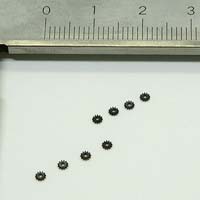

| 5. Super small module gear Usage: Gear related to a cell phone Material: PEEK Die: 1 cavity Reason of development: New development A manufacturer in the cell phone industry designed a super-small module gear, but since the teeth were very small and a torque was applied to the gear, typical engineering plastics would not work. Nichiei recommended a suitable material to the customer, based on our knowledge of performance needs and conditions of use, plus over 20 years of experience with super-engineering plastics. Also, since this was such a small part, gate placement and use of ejector pins required special knowledge. |

| 6. Pipe with an internal diameter of 0.5 and length of 72 mm Usage: Medical component Material: PES Die: 1 cavity Reason of development: New development (trial production) A customer needed a funnel-shaped end for a clear pipe with an internal diameter of ?0.5 and length of 72mm. Since burring could not be tolerated, the customer could not have the part machined from rod stock. Nichiei was asked for advice and began the development process. Since the injection pressure was very high, it was extremely difficult to keep the mold pin of ?0.5 standing straight during molding. Also, the length of 72mm was nearly impossible to achieve with injection molding. As a result of much trial and error, Nichiei has been able to produce parts with the necessary degree of precision. |

| 7. Super small screw Usage: Small screw Material: PEEK, etc. Die: 1 piece Reason of development: Trial production Nichiei manufactured this part to meet a customer’s need to replace an extremely small metal screw with a plastic screw. The screw was so small that typical engineering plastics did not satisfy the required strength of the screw thread. Nichiei worked with the customer to recommend the appropriate material(s), design and build the tool, and produce prototype parts. |

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.