Drones are tasked with providing state-of-the-art autonomous capabilities, unique movements, automated inspection, urban delivery solutions and advanced military operations. They upgrade agricultural farming technology, provide safety and logistic solutions and report key disaster and engineering mapping. PT components such as motors, controllers, and sensors are an integral part of their core structure.

Consider the following scenario: guided by vision sensors, a robot spots a product on a moving conveyor, determines its exact position and, in one fluid motion, picks it up and places it into a waiting assembly, carrier tray, or shipping container. What human operators once found tiring—or at least tedious, the robot performs flawlessly, hour after hour, even long after its flesh-and-blood coworkers have gone home for the evening.

.

Operating for long hours, under extreme loads, in high temperatures and dusty environments, ongoing wear is a significant challenge for open gears. This can lead to unplanned downtime and reduced equipment life—creating a barrier to effective operations. Leading mining and cement companies use advanced grease technology and technical inspections to help prevent open gear failure, optimize service life and ensure the smooth running of their operations.

.

Bosch Rexroth continues to expand the ctrlX platform with new capabilities and automation enhancements. The control platform ctrlX COREplus is now available with AI functions on all performance levels. In the area of motion and drives, Bosch Rexroth is presenting compact, energy-efficient, and cabinet-free drives from the ctrlX DRIVE portfolio, which cover virtually all performance ranges. These are complemented by the Motion, CNC, and Robotics software ctrlX MOTION, which is ideal solution for automating production machines and systems. PTE recently had a great conversation with Garrett Wagg, product manager, controls at Bosch Rexroth on new developments in mobile robotics.

.

The load limit diagram of a motor spindle serves to graphically represent the permissible operating range as a function of parameters such as rotational speed. It enables a quick assessment of the conditions under which the spindle can be operated safely and reliably without exceeding mechanical, thermal or dynamic limits. Such a diagram is a key tool for the design, selection and evaluation of spindle systems in mechanical engineering particularly in the field of machining where high demands are placed on precision, performance and service life.

.

This paper examines the selection process, operation, maintenance practices, and state of a Sumitomo gearbox after over 24 years of operation. It is demonstrated that a quality product and careful consideration of all these factors are essential for a longer service life of the gearbox. Detailed information is provided on the operation of the gearbox, as well as the maintenance practices that should be taken to ensure its longevity. Finally, the paper examines the state of the gearbox after over two decades of use and how all these factors result in lowering carbon emissions.

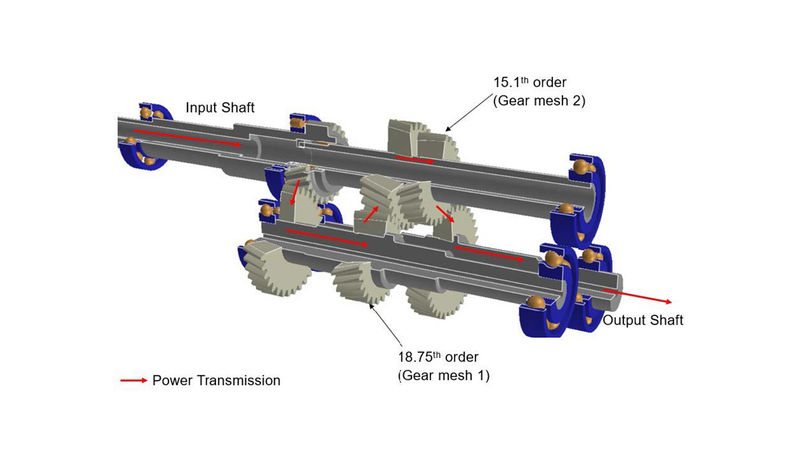

In the realm of tractor gearbox applications, gear whine noise has long been a persistent challenge that significantly impacts the user experience and overall perceived performance of the vehicle. This paper delves into a comprehensive study that discusses the approach to tackling this issue through a combination of design optimizations, simulation techniques and physical validation processes.

Rolling bearings possess especially low friction characteristics. They make it possible to reduce bearing friction by half, offering the construction machinery sector the opportunity to achieve significant carbon dioxide savings without imposing high development costs. This article will examine the current solutions from Schaeffler.

The drive system choice is dependent on key motion features of your application. Lead screws offer self-locking capabilities, while ball screws require brakes to prevent back-driving. The choice between them hinges on efficiency, cost, precision, and speed, with the screw drives themselves paired with a linear guide for optimal performance.

Bellows couplings are commonly used in applications requiring precise rotation, high speeds, and dynamic motion transmission. With zero backlash and a high level of torsional stiffness, they offer clear performance advantages in many servo-driven systems.

The Simplicity self-lubricating linear plain bearings are built to last, and they will often out-perform and last longer than a traditional linear ball bearing. Called the “little red bearing” by loyal customers, they have been a popular replacement for failing ball bearings. Simplicity plain bearings will not catastrophically fail.

The difference between a smooth-running drive and constant headaches? The right timing belt and pulley plus a whole lot more. Discover what works, what doesn’t, and put your design skills to the test—engineer your best system yet!

Discover how Regal Rexnord’s Bauer™ PMSM gear motor helped a transportation company streamline inventory, cut energy use, and save $80,000 annually. Learn how this scalable solution delivers financial, operational, and sustainability gains across facilities.

The robust performance of the robot welder at Centerline Brackets led the Florida-based manufacturer to an exceptionally rapid return on investment, achieved in less than three months. The Universal Robots' collaborative robot dramatically cut production time and addressed labor shortages while ensuring consistent weld quality for heavy-duty brackets.

Feb 27, 2026

Greene Tweed has announced the successful development and deployment of its Metal-Spring-Energized (MSE) seals for McLaren Mastercard Formula 1 Team’s limited-slip differential clutch pack. The collaboration represents a significant milestone in the ongoing partnership between Greene Tweed and McLaren Racing, which continues to fuel advancements in motorsports engineering.

Jun 1, 2026 - Jun 4, 2026

Cleanpower 2026 (Houston) grows businesses by gathering key decision makers and stakeholders across the wind, solar, storage, hydrogen, and transmission industries for discussion, deal making, networking and a whole lot of fun.

Jun 15, 2026 - Jun 18, 2026

Mar 17, 2026 - Mar 18, 2026

Current Issue

Current Issue

Archives

Subscribe

Buyer's Guide

Accessories Actuators Adjustable Speed Drives Bearings Belting & Belt Drives Brakes Chain & Chain Drives Clutches Controls Couplings & U-Joints Fluid Power Gear Drives Gear Manufacturing Services Gears Industrial Hardware and Machine Parts Linear Motion Devices Lubrication Motors Resources Seals Sensors Services SoftwareThe Power Transmission Engineering Buyers Guide is your complete directory of suppliers of mechanical power transmission components, including great companies like these.

VIEW ALL