The concept allows for versatility as needed, but it can be used, for example, to precisely control electromechanical pressure to seal filled bags or to join multiple bags in a single group. Embossing product logos or promotional labels onto existing containers is another application.

Until the advent of smart mechatronics, machine builders may have developed their own mechatronic assemblies by ordering and integrating separate components. However, this process is often cumbersome and time-consuming.

In a typical scenario, the mechanical engineering group may be responsible for specifying and ordering one set of components, while the electrical group orders its components. Not only is this more challenging for the purchasing department, but the engineering staff is then tasked to make it all fit together physically and program the functionality. Smart mechatronics can eliminate that complexity, providing a complete realization of the plug-and-produce concept.

Bosch Rexroth has simplified the process to achieve this concept. First, they are deploying advanced, well-designed online configuration tools that make it possible to specify and order all the components as a single part from one supplier.

The engineers at a packaging OEM can enter parameters such as stroke, workpiece size, and cycle time, which then generates an output that can be verified and includes a complete set of CAD drawings that can be integrated into the overall digital plan of the FF&S system. In this way, a complete bag-sealing tool or subsystem can be ordered as one part number with a single mouse click and shipped with preprogrammed motion sequences ready for implementation.

In addition, a system like this can come with preinstalled operating software and automatic parameterization of the servo drive, so no motion control programming knowledge is needed to bring it online. It features a drag-and-drop graphical user interface that lets operators build production sequences—e.g., for sealing together a set of juice bags—simply and intuitively.

A key advantage the Smart Function Kit for Handling offers for packaging systems integrators and end-users is its intuitive online configuration and ordering tools.

The ”smart” in smart mechatronics includes more than just simplifying ordering, integration, and startup. These systems can also incorporate force sensors that can track and report each motion sequence: was the proper force applied, for the proper length of time, to ensure a correct seal?

As this sequence is typically repeated hundreds or even thousands of times per hour, the system’s controller can measure and record each motion cycle for quality control purposes. This kind of information can give warning about malfunctions or other issues, which can be used to drive preventive maintenance programs, as well as incorporated into overall equipment effectiveness (OEE) analysis.

This is the kind of critical, real-time data that’s essential to Industry 4.0 production systems—and it is as easy to implement and utilize as the rest of the smart mechatronics kit operating software.

Versatile New Handling Systems with

Smart Mechatronics

Many packaging lines use automated mechatronic handling systems extensively, both linear robots and multi-axis systems. Whether for transferring material from one part of a production line to another, or for end-of-line applications such as case packing and palletizing, linear robots and multi-axis mechatronic systems provide high performance and reliability.

They are commonly built-in similar fashion to other mechatronic systems: linear modules, servomotors, drives and controllers ordered separately, along with individual orders for items such as power and communications cabling and the HMI (often pieced together from different vendors at the best cost for each item).

Then the systems need to be integrated. One common challenge for handling systems is connecting the x, y, and z axis linear modules, especially if their physical connections don’t incorporate well-engineered physical interfaces. Another time-consuming engineering step is planning and implementing the cable runs in the system—including all the engineering drawings that document these steps.

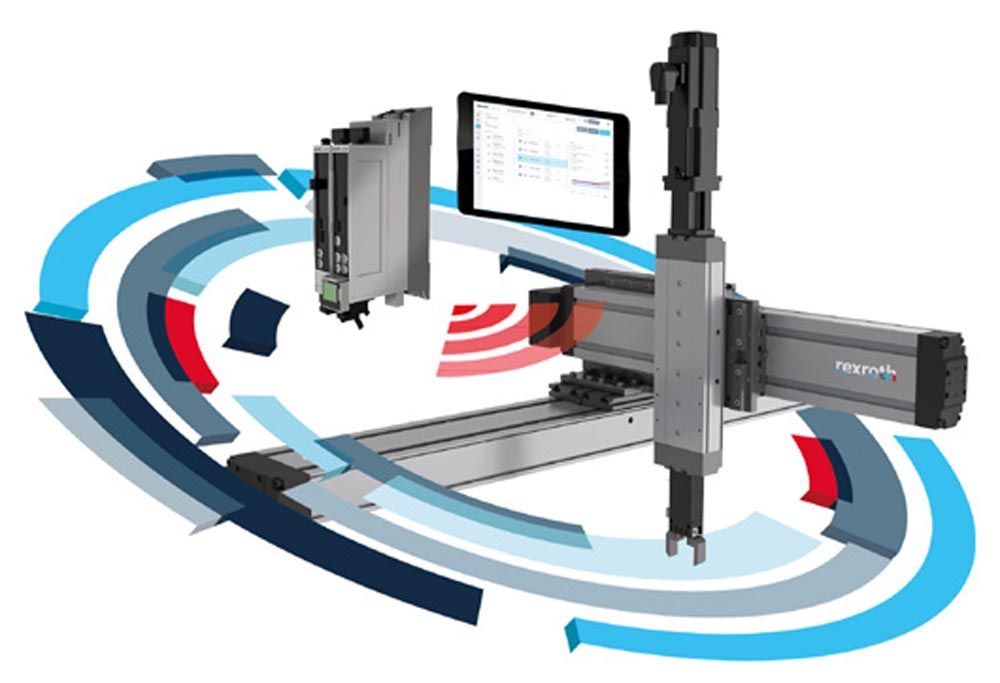

Similar to the Smart Function Kits from Bosch Rexroth for pressing and sealing operations, the new generation of smart mechatronic handling systems will also provide true “plug-and-produce” platforms for Cartesian and multi-axis systems.

Smart mechatronic handling systems will utilize intuitive, well-engineered online configuration and ordering tools that streamline the process for specifying all the components needed for a given packaging application. This is particularly useful when multiple linear modules of different sizes and weight-bearing capacities need to be ordered and integrated.

Without smart mechatronics commissioning systems, it can be time-consuming to capture all these key specification details when ordering linear modules and servomotors separately. Equally valuable, smart mechatronics for handling systems will come with preinstalled operating software and automatic parameterization of the servo drives. Drag-and-drop programming of motion sequences to configure a range of common pick-and-place functions can also be provided.

This will make it possible for packaging system OEMs to quickly design and integrate single-axis or multi-axis handling systems as part of a new installation. They will also be able to rapidly update existing packaging end-of-line systems when changes in production or product mix call for Cartesian functionality.

And as with other smart mechatronics solutions, these smart mechatronic handling systems will support real-time data capture and integration with higher-level machine controls, as well as the ability to export data via interfaces such as OPC UA to provide valuable productivity and quality information.

Plug-and-Produce Technology

Transforms Mechatronics

Smart mechatronics offers a new, Industry 4.0–ready way to simplify the effort required to configure, order, integrate and begin using high-value mechatronics systems in packaging machine applications. Complete solutions, delivered in a single package or “kit” that’s ready to plug-and-produce, has the potential to reduce the time and cost required to build packaging machines.

For packaging companies, as well as the OEMs supplying their production systems, there are advantages to working with a single mechatronics supplier with a complete portfolio of products and components, easy-to-use online configuration tools and a proven record of creating high-performance smart mechatronic solutions specifically for the demands of today’s packaging industry.

boschrexroth-us.com

Similar to the Smart MechatroniX function kits for pressing and sealing operations, the new generation Smart Function Kit for Handling systems will provide true “plug-and-produce” platforms for linear robot and multi-axis systems.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.