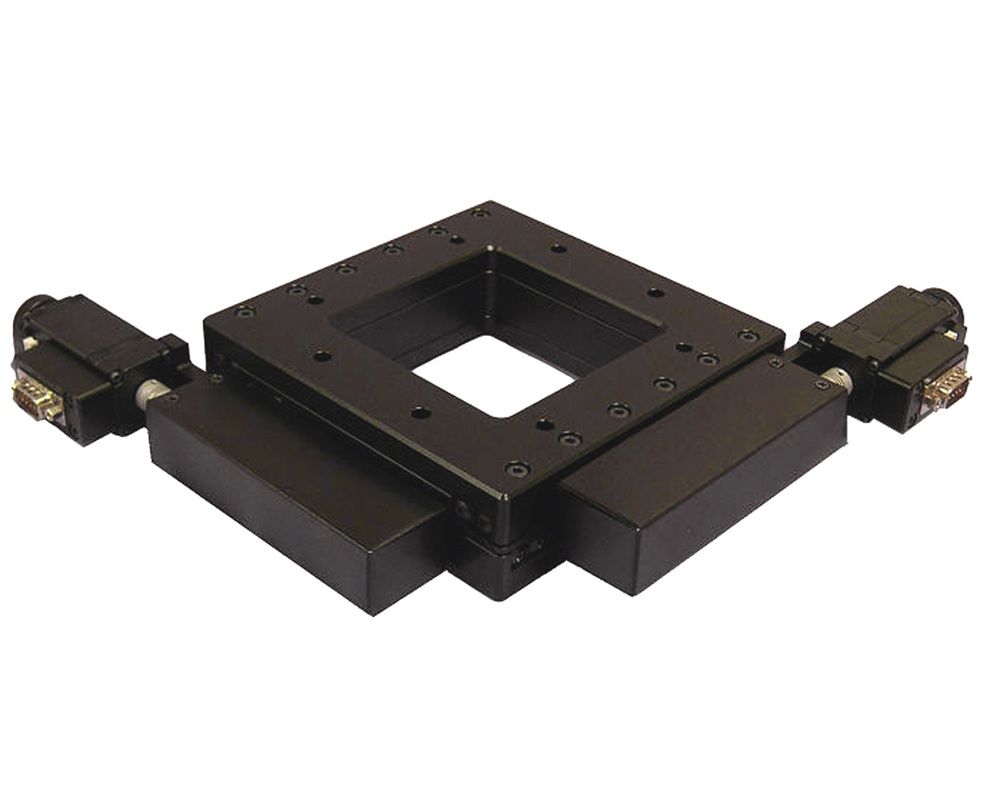

OES Introduces Open Aperture Alignment Stage

The submicron, AU200-50x50 open aperture alignment stage from Optimal Engineering Systems, Inc. (OES) with a 90 mm by 90 mm open aperture is the ideal choice for applications requiring extreme precision such as: semiconductor wafer inspection and handling, laser drilling and machining, testing, scanning, inspection, measurements, optical applications, medical diagnostic devices and instrument assembly, calibration and inspection, 3D printing and alignment. The linear travel of the X and Y axes is 50 mm by 50mm, and the resolution of each axis is 5 microns (non-micro-step) or 0.5 microns (with 10 micro-steps per step motor driver in use), the repeatability is 1.5 microns. The 1 mm per-turn lead screws and preloaded V-groove and crossed roller bearings contribute to the high precision and stiffness of the AU200-50x50 open aperture alignment stage.

The XY table measures 155 mm x 155 mm and features a precision pattern of drilled and threaded mounting holes to facilitate the addition of tooling or fixtures. This low profile black anodized aluminum XY stage is easy to integrate into new or existing systems. The two-phase stepper motors with knobs for manual adjustments of each axis are standard for the AU200-50x50 open aperture alignment stage, however, the knobs can be replaced with 500 cycles-per-revolution quadrature optical encoders for position verification. Compatible multi-axis motion controllers are also available from OES and the AU200-50x50 open aperture alignment stage can be ordered as a complete plug-and-play system.