GWJ Technology Presents Advanced Features for Precise Drivetrain Calculation

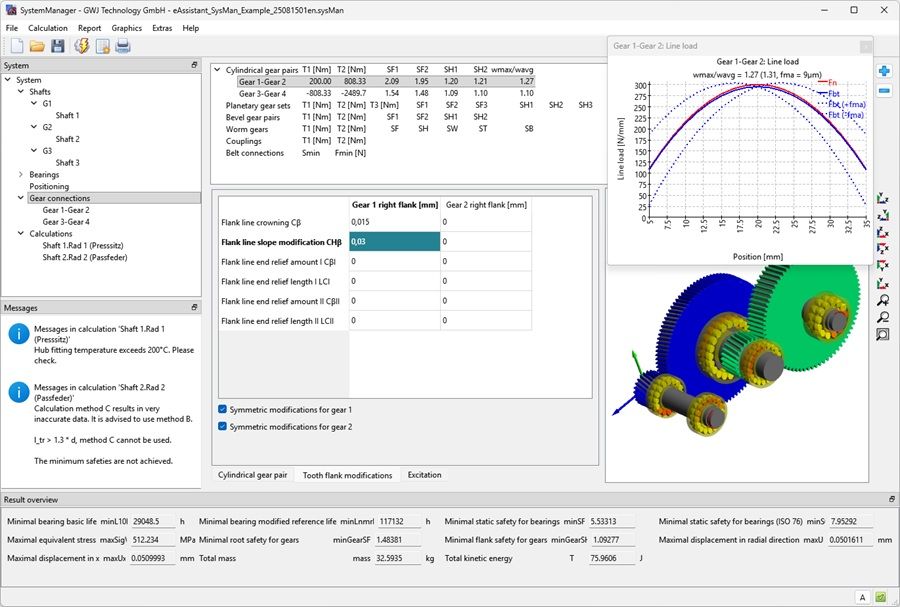

GWJ Technology GmbH from Braunschweig presents the new version of its SystemManager, which serves as an extension for the established calculation solutions eAssistant and TBK. With numerous innovations and optimizations, the software provides engineers with enhanced capabilities for modeling, calculating, and analyzing complex drivetrain systems.

A significant advancement is the integration of shaft-hub calculations for parallel keys, interference fits, and involute splines. This allows calculations and data to be managed and exchanged directly within the system, with the corresponding individual modules being accessible in the system environment.

The eAssistant or TBK modules can be opened directly in the system. Additionally, a new message window enhances transparency by centrally displaying notifications and results from the system calculation, as well as the bearing, gear, and shaft-hub calculations. The user interface has also been optimized: a new toggle in the status bar now allows for automatic recalculation after any input changes. All results, including graphics, are immediately updated, enabling users to instantly see the effects of parameter changes.

Furthermore, the STEP import for shaft geometries has been enhanced. A defeaturing option allows elements such as chamfers, radii, or holes to be removed. The bearing databases from SKF and NSK, along with the corresponding catalog data, have also been updated.

At the system level, multiple load cases can now be defined and flexibly selected for calculations.

The calculation of the line load distribution for gears has also been further developed. A supplementary flank line deviation (fma) can now be specified for the gear connection. This allows alignment errors, such as manufacturing-induced flank line deviations of the gears or parallelism errors of the shafts, to be taken into account. The line load calculation is then performed with the additional fma, where only the tooth engagement stiffness at constant gear tilt angles is considered. This is then incorporated into the loadbearing capacity calculation according to ISO 6336 Method B via the face load factor.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.