Varvel Focuses on High Modular Gearboxes

The need to keep customers in all parts of the world constantly supplied while minimizing stock in distributors' warehouses, and a range of gearboxes offering many thousands of possible configurations were the two elements that encouraged Varvel to develop the concept of modularity and design end products that could be configured in just a few simple steps using kits. Today, modular design is a key strength and has made Varvel a model for advanced Italian engineering.

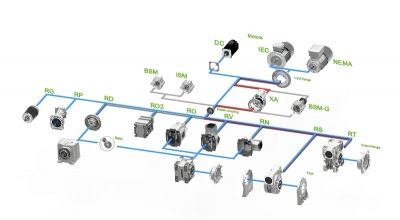

Varvel is present in over 60 countries around the world. In 2000, the company decided to extend the concept of modularity already applied to its worm gearboxes to its entire product range. Varvel's parallel shaft and bevel-helical gearbox and gearmotor ranges were the result of this decision.

Today, Varvel's entire product range, which extends up to 3,400 Nm of transmissible output torque and 22 kW of installable power, is designed and made using modular kits to create thousands of different configurations. Every parallel shaft and bevel-helical gearbox is made up of an input kit (motor flange and coupling), an intermediate kit (gear pair) and an output kit (casing, output shaft and gear train) to which accessory kits (like torque arms, feet, flanges etc.) can be added. Within each size, kits can easily be selected to create different gearbox types (parallel shaft or bevel-helical), different reduction ratios and an impressive choice of outputs (shafts) and inputs (motor sizes).