Trelleborg Presents Sealing Solutions for Speed Reducers

The spectrum of machinery and equipment used in industrial automation includes everything from electric motors to robotics and each has its own unique attributes and sealing requirements. David Kaley, Trelleborg global segment manager for industrial automation, shares his expertise on speed reducers covering what they are, how they work and key considerations for correct sealing in this article.

Back to Basics: Speed Reducers

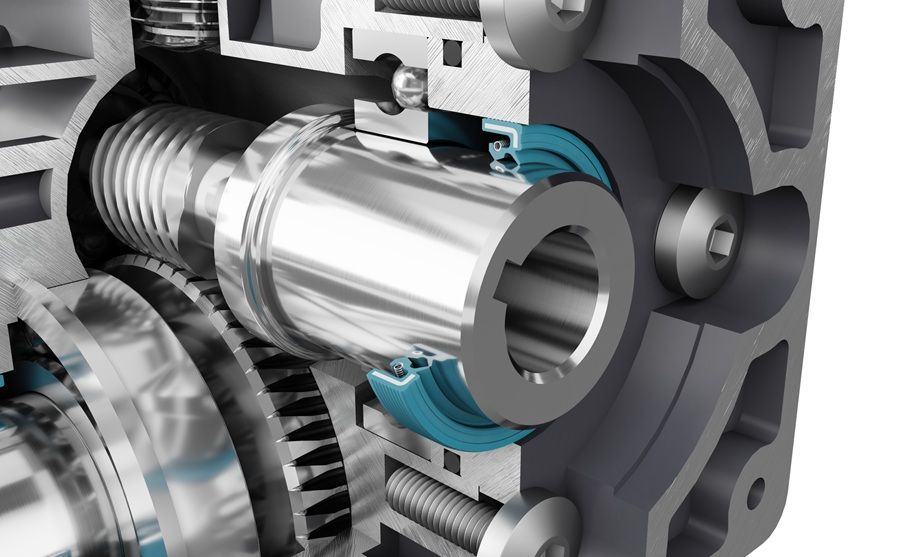

A speed reducer is a mechanical system of gears in an arrangement where input speed can be lowered to a slower output speed but maintain the same or more output torque. The operation of a speed reducer involves a set of rotating gears that are connected to a shaft with a high incoming speed, which is sent to a set of rotating gears where the speed or torque is changed.

The terms speed reducer and gearbox are often used interchangeably but there are some distinctions. Gearbox is a broad term that refers to any device using gears to transmit power from one part of a machine to another. Gearboxes can change the speed, torque and direction of the power source. They can either increase or decrease speed, depending on their design.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.