PEM to Develop Magnet-Free E-Motor to Reduce Production Costs

The Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University has entered the two-year “NAFTech” research project funded by the German Federal Ministry for Economic Affairs and Energy. Together with the Institute of Electrical Energy Conversion (IEW) at University of Stuttgart and the Chair of Manufacturing Automation and Production Systems (FAPS) at FAU Erlangen, the PEM team will be developing an electric motor as a traction drive that does not require the use of rare-earth elements and will still offer a great degree of compactness, efficiency, and high torque density.

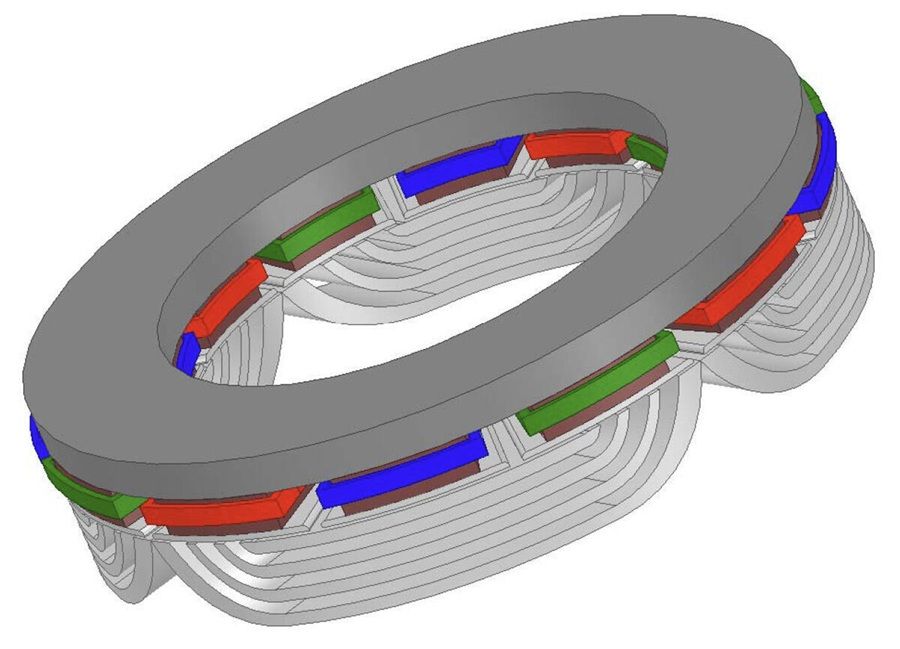

The background to this is that current axial flux machines (AFM) meet these positive criteria but are almost exclusively dependent on rare-earth magnets. To avoid the use of those cost-intensive and increasingly scarce resources, the radial flux synchronous reluctance machine (RF-SynRM) is currently considered a sustainable, robust, and overload-capable alternative. In turn, this entails compromises in terms of installation space and torque density. The “NAFTech” project therefore focuses on the concept of an axial flux synchronous reluctance machine (AF-SynRM) that combines the respective advantages of AFM and RF-SynRM.

Validation through partial demonstrators

“Axial flow machines are currently characterized by relatively low production volumes, manufacturing processes that are not yet fully developed, and special requirements in terms of tolerances and design processes”, says PEM Director Professor Achim Kampker. “NAFTech” therefore pursues an integrated approach to topology, multi-domain machine design, and production methods, supported by data-based optimization of tolerance chains. During the project, the simulative design of the machine and the suitability of the manufacturing processes will be validated with the aid of specially constructed partial demonstrators.

AF-SynRM promises economic advantages, especially for small and medium-sized enterprises (SMEs), as it enables stable production costs and reduces dependence on volatile prices, which are prevalent with rare-earth magnets. “A magnet-free motor generally also reduces material costs by up to 50 percent, which can strengthen the competitiveness of SMEs and lower barriers to market entry”, Kampker says. Meanwhile, there is growing pressure to develop sustainable solutions to reduce carbon emissions and comply with legal requirements. According to PEM, early investment in magnet-free technologies can give SMEs an innovative edge and open up opportunities in high-growth markets. Photo above courtesy of IEEE Explore.

pem.rwth-aachen.de/go/id/brigdm/lidx/1

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.