GWJ and Ovako Collaborate on Gear Modules

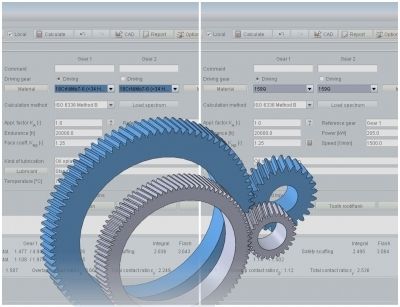

The Swedish company Ovako is a producer of engineering steel for customers in the bearing, transport and manufacturing industries, and a subsidiary of Nippon Steel Sumitomo Metal Corporation. The integration of the clean steels 159X and 159Q into GWJ´s cylindrical gear modules took place in close cooperation between Ovako and GWJ Technology.

159X and 159Q are based on case-hardening steel of the type 18CrNiMo7-6. Because of significantly smaller-sized impurities in the steel, the steels have modified Woehler curves.

Within the static strength, the steels are comparable with 18CrNiMo7-6. In the fatigue strength range, the IQ-Steel 159Q (Isotropic Quality ultra clean steel) is designed to increase efficiency by 30 percent for the flank load capacity and 60 percent for the tooth root load capacity. The fatigue strength values are based on Ovako's in-house investigations and external verifications at WZL of RWTH Aachen University and at the Gear Research Centre (FZG) of Technical University of Munich.

The BQ-Steel 159X (Bearing Quality clean steel) delivers slightly smaller performance gains compared to 18CrNiMo7-6 and can be taken to improve existing designs. 159Q is ideal for new design solutions. It may be advantageous to focus on optimized scuffing load capacity, usually resulting in better gear efficiency and lower power losses.

From GWJ´s point of view it can be said that Ovako steels open up completely new design possibilities for gearboxes and offer significant potential to increase the efficiency of gear drives and gear components. Both steels, 159X and 159Q, are available in all three GWJ software solutions, the web-based software eAssistant, the desktop application TBK and the special software GearEngineer for 5-axis milling of gears.