From Assembly Lines to Algorithms

A Discussion on AI and Digital Transformation with Siemens Digital Industries Software

Siemens Digital Industries Software is in the business of solving shop floor challenges across manufacturing. From automotive to packaging, industrial machining to aerospace, the company builds systems with AI and digital tools to enhance efficiency, sustainability and quality control. Late last year, I had the opportunity to speak with Raul Garg, vice president industrial machinery, Siemens Digital Industries Software at the Motion + Power Technology Expo in Detroit. Our conversation began with the role AI will play in industrial machining, particularly for small to medium-sized manufacturers.

“Re-industrialization is happening globally, and, in its context, we’ll see a greater emphasis on AI and digital transformation in the future. AI is going to enhance capabilities to improve manufacturing processes, bringing more efficiency and flexibility to the shop floor,” said Garg. “The backbone of these efforts is going to be digital transformation. You need to have the digital capabilities to leverage the value of AI. Given all the investments that are being committed by many large corporations for manufacturing in the U.S.—potentially around $1 .8 trillion based on our research—you’re going to need to find different and unique ways to support these markets.”

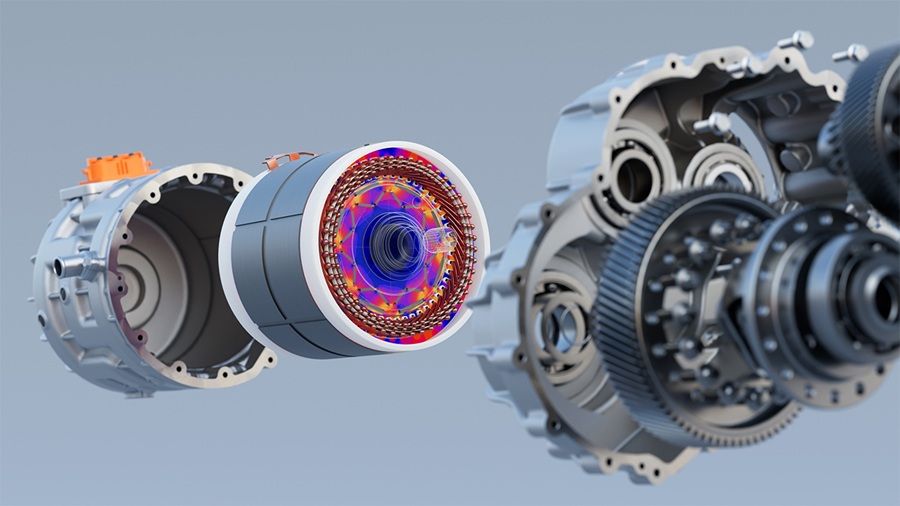

In 2025, Siemens completed the acquisition of Altair Engineering Inc. With this acquisition, Siemens extends its leadership in simulation and industrial AI by adding new capabilities in mechanical and electromagnetic simulation, high-performance computing (HPC), data science and AI. The addition of the Altair team will further enhance the most comprehensive Digital Twin and make simulation more accessible, so companies of any size can bring complex products to market faster.

Integrating Altair’s capabilities in the areas of simulation, HPC, data science and AI enhance the ability of Siemens to drive more efficient and sustainable products and processes. Now, all Siemens customers, from engineers to generalists, will have access to new simulation expertise, can optimize their high-performance computing processes, create new AI tools and perform data analytics to help accelerate innovation and digital transformation for companies of all sizes.

One area already undergoing significant change is machining capabilities. Garg said engineers and machinists want to know their machines are running without interruption and producing parts with maximum efficiency. This follows an industry-wide shift toward offering machines-as-a-service versus selling machines outright.

Siemens philosophy in this area is balancing revenue growth, workforce optimization and sustainability through machine-as-a-service strategies. Creating a digital twin of the customer’s service operations, for example, could unlock valuable insights into equipment performance and parts inventory.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.