Solid Edge enables manufacturers to create a comprehensive digital twin of their products and includes solutions for mechanical design, electrical design, simulation, manufacturing, and technical publications. It also includes solutions for data management for all the technical data that’s created and consumed when supporting the comprehensive digital twin.

Ultimately, Solid Edge facilitates collaboration both within manufacturing companies and with external resources, including suppliers and customers—that makes it the on-ramp to digital transformation and enables us to help customers accelerate their digital transformation with Solid Edge 2024.

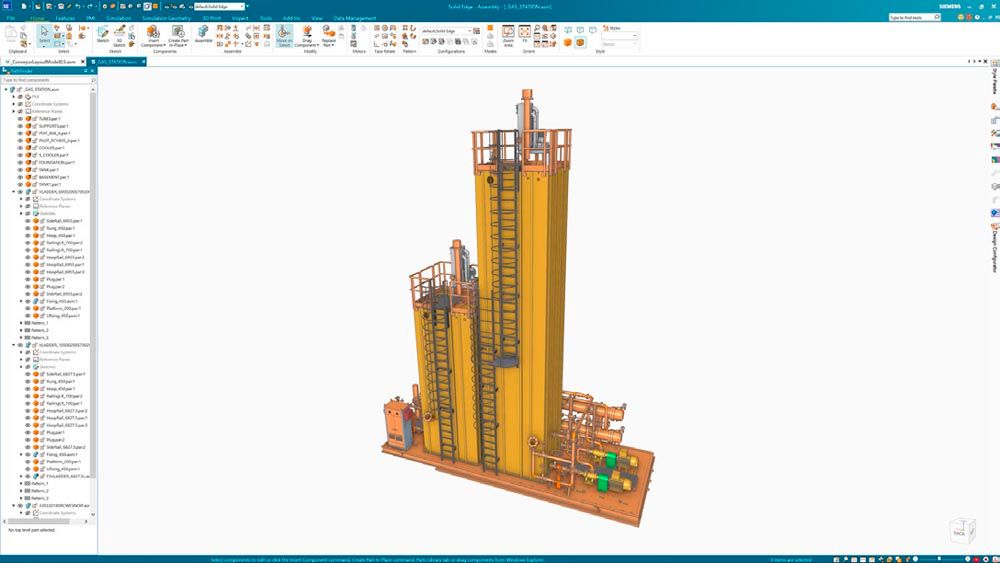

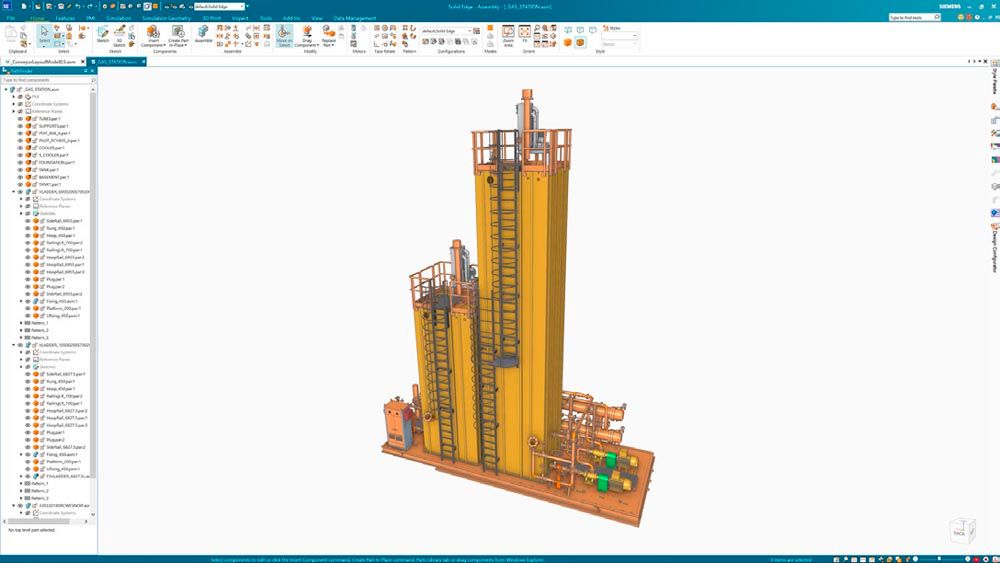

Insert and manipulate preconfigured models quickly and easily at no cost with Solid Edge Design Configurator. As intelligent datasets with predefined rules, a vast array of preconfigured models can be inserted and automatically adjusted to match the assembly to help simplify workflows and improve productivity.

What are the highlights of the Solid Edge 2024 update?

With this year’s release we continue to push the boundaries of product development technology by empowering users to design more intelligently across every aspect of product development. With a continued focus on the user experience and large assembly performance, Solid Edge 2024 introduces functionalities and enhancements to automate and speed design as well as collaboration. A few highlights I’m proud of—the nine times faster graphical performance, artificial intelligence (AI) driven assembly relationships, great advancements in intelligent dimensioning, and so much more.

What have the beta testers said about this update?

As with every year, our beta customers have already had the opportunity to experience Solid Edge 2024. Summing up the general feedback nicely is the comment from Carsten Oestmann, the leader of the CAD team at industrial machinery specialist, Focke & Co:

“Each year Solid Edge gets better and better. This year, everything is faster. With faster reaction times in large assemblies, everything feels more fluid. I can’t wait to share it with my team. Large assemblies now load and rotate at least 50-percent faster. That’s the type of performance that can improve every one of our workflows.”

Artificial intelligence is a hot topic across the technology world—how is Siemens using it in the 3D design and engineering world?

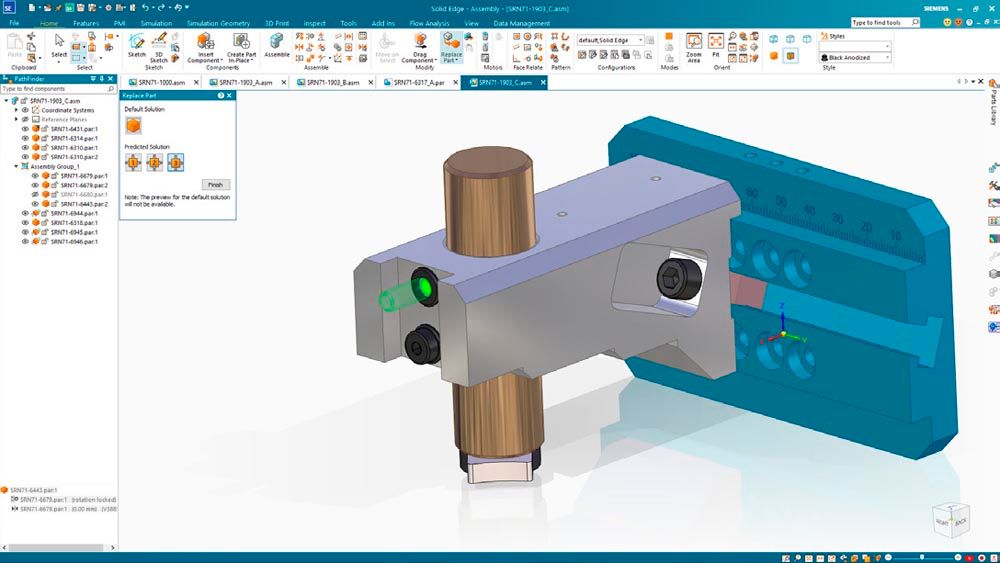

One of the key highlights for this update is our continued work applying AI technologies in the design process to speed things up—removing repetitive work and taking advantage of machine learning to help our users be more productive. A great example is the new AI-enhanced ‘Replace Part’ command that uses AI to predict solutions for replacing a component occurrence within an assembly. The AI looks at the geometry of the part a user is replacing alongside the new part and presents viable solutions—they then click the correct solution and they’re done. It saves effort, can speed up product iterations and redesigns by not having to create those relationships manually, and works equally well with standard, imported parts, as it does with native data.

What do your customers think about using AI as part of their day-to-day activities?

AI, when implemented in tools like Solid Edge, can remove repetitive tasks and free up resources in an engineering team. The reality is that CAD users are often carrying out tedious, repetitive tasks—so why not let the computer do that? The best answer is to quote another beta tester, David Iverson of separable reciprocating gas compressor manufacturer, Ariel Corporation, who loves that it allows his team to focus on the real challenges.

“Solid Edge 2024 helps us work smarter and be more productive. Incorporating AI into our design processes will cut down time spent on tedious tasks, letting us do more of the fun stuff,” Iverson said.

AI is also useful in an industrial context when used alongside other advanced technologies—look at the work we have been doing for the past few years on generative design, where we use simulation technology to automate concept design, based on loads and constraints in a product. AI can change how we design, but it needs to sit alongside our existing technologies—and with capabilities such as synchronous technology, we believe that Siemens has the optimal portfolio of software that can help users overcome real-world barriers to innovation by taking advantage of AI assisted design.

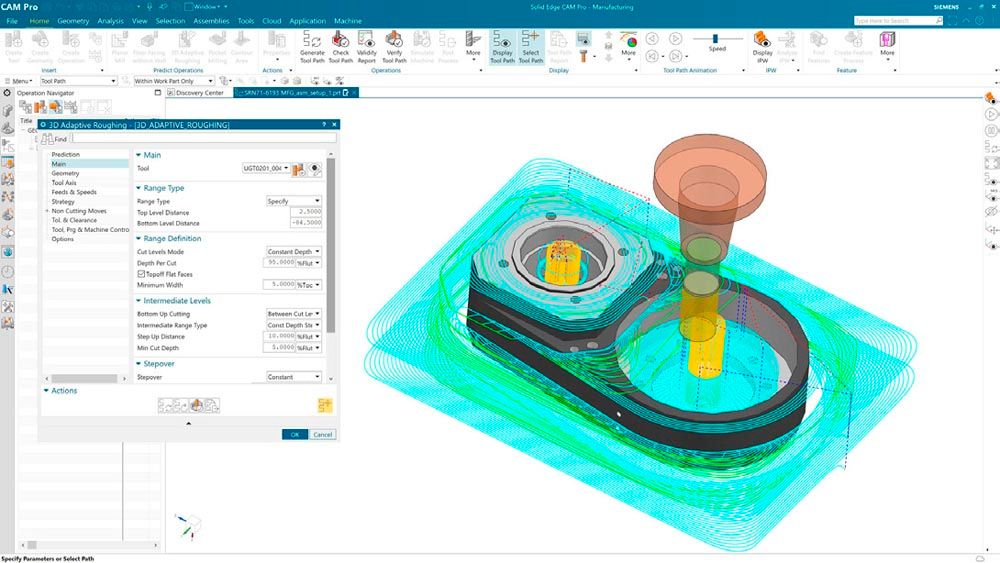

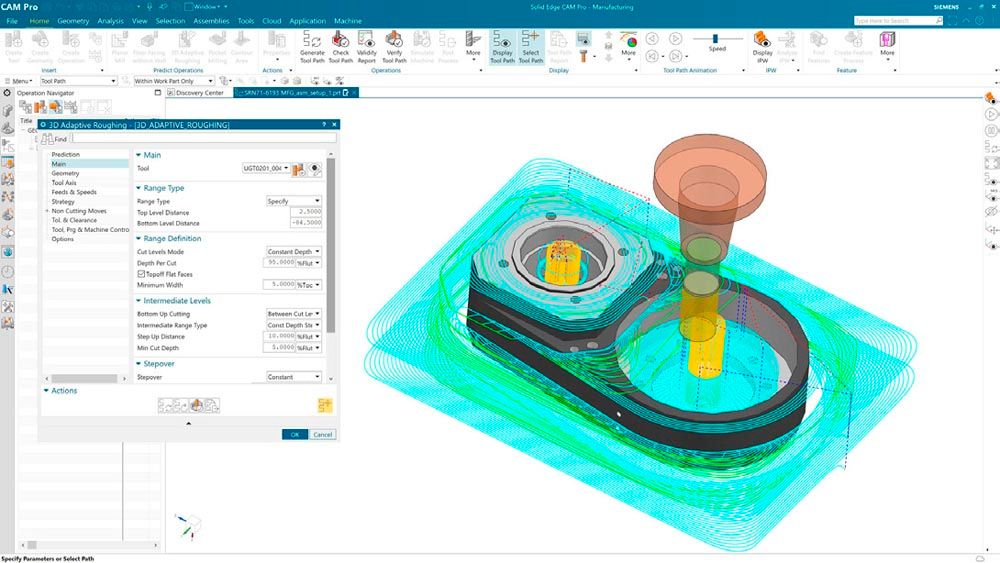

Faster programming and more efficient machining cycles are now possible due to the introduction of 3D Adaptive Roughing operations. High-speed, bottom-up cutting strategy enables methodical removal of material between cut levels by re-cutting the stock at decreased levels by stepping upward.

Alongside the headline-grabbing AI updates—how else are you improving users’ productivity?

Whether it’s improving our large assembly performance by nine times for this release or rethinking how we can accelerate frame and tube design, enabling users to go faster and with more intelligence built into their product models is fundamental.

A notable example of how Solid Edge 2024 supports improved productivity is the new ‘Trim Tubes’ command. Frame design is something that happens in many of our customer sites, whether that’s industrial machinery, factory cell design or motorsport. This new tool allows users to identify overlaps very quickly in a framework and trim those tubes, readying them for manufacture and fabrication with a few simple clicks. It might not be flashy or headline grabbing, but for those involved with frame design daily this update is a game changer.

Speeding up the design process is great, but how is Siemens helping the wider manufacturing enterprise?

The challenges facing today’s manufacturers are many, ranging from supply-chain complexity to the drive for innovation, to customers looking for greater choice and customizability. The last challenge is something that our customers are telling us is a key pressure point—where the increase in product variants is presenting a challenge not only from an engineering point of view, but across the enterprise in terms of sales support. To help our customers overcome this challenge, we have worked on Solid Edge Design Configurator, our rules-based design capability. Firstly, we are now able to include preconfigured models in Solid Edge Design Configurator, so the engineering team can quickly and easily place intelligent datasets of common items such as ladders, conveyors and enclosures that adapt according to design rules—again, something that is repetitive, and ideal for automation.

Extending the use of rules-based design further, we’ve also introduced Solid Edge Design Configurator Connect. This is a user-friendly web-based configurator that manages the most complex pricing and product configurations, allowing users to configure online in any browser simply and easily. It then automatically generates sales documentation, including 3D models, which allows customers to offload some of the work that would traditionally be done in the engineering office and move it to the hands of the sales and marketing team.

youtu.be/Lj5Hi5-mO1s?si=hEl6_PHdHM3f_nNo

“Solid Edge enables manufacturers to create a comprehensive digital twin of their products and includes solutions for mechanical design, electrical design, simulation, manufacturing, and technical publications.” Dan Staples, Siemens Digital Industries Software |

How does Teamcenter Share tie all this together?

Teamcenter Share builds on our previous cloud-based data sharing and collaboration capabilities, previously known as Xcelerator Share, a common service offered as part of any subscription to Siemens Xcelerator portfolio and allows the sharing of data and collaboration around that data wherever it is needed. Teamcenter Share is now embedded in Solid Edge 2024 and provides subscribers to Solid Edge SaaS with a streamlined collaboration platform to help them work with their entire team, including partners and customers.

Through Teamcenter Share users can view, interact with, and collaborate around, a wide variety of data formats (from both Siemens and third-party systems). It also offers built-in data management capabilities: files can be checked in or out and access always controlled, projects managed, and tasks assigned—all from within the Solid Edge interface without the need to use another application. If a partner or team member needs access but does not have Solid Edge available, the same Teamcenter Share experience is also available via a web browser, on any device, opening collaboration for those that need it when they need it.

One of our customers, Hall Designs, uses Solid Edge to design vehicles for the off-road racing industry. They use Teamcenter Share to better communicate with their clients during the iterative design process. Their clients can easily view, measure, and mark up CAD models within the 3D development space using a browser-based interface accessible from any device. In addition, collaborators can view and comment on files, view model sections and cutaways, take measurements, change units, and add text-based annotations—all in real time for other team members to see. This eliminates the need for back-and-forth emails with PDF attachments for those who can’t open CAD files. Hall Designs reports that Teamcenter Share enabled them to reduce the time it took to share designs by 75 to 80 percent and accelerate the product revision process by 20 to 25 percent.

solidedge.siemens.com/en/solutions/products/complete-product-development-portfolio/solid-edge-2024/

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.