The transition from fossil powered cars and the increases in electric motor efficiency have implications that many politicians do not understand and even those in the industry that are familiar with motors and power can easily overlook: the limited supply of crucial raw materials.

20 years ago most industrial motors were AC induction motors, as were EV motors 10 years ago. To improve motor efficiency and to make motors smaller and lighter, permanent magnet (PM) based motors are steadily replacing the AC induction motors. This means our demand for high energy magnets, specifically Neodymium-based with current technology, is ever increasing. As we transition larger motors from AC induction to PM based ones, we need increasing amounts of rare-earth magnets, most of which are made in China.

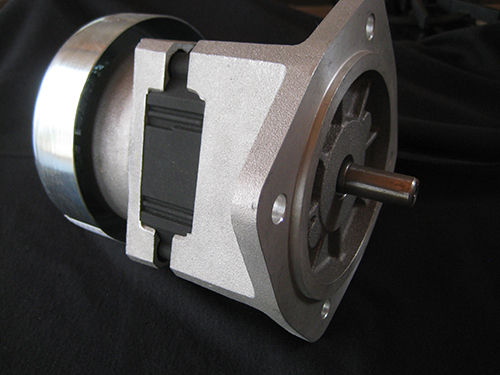

SR165 => A 4.5 HP Switched Reluctance Motor.

It was not that long ago when China flexed its muscle and Neodymium prices shot up, which paralyzed the motor industry and led to inflation in the motor costs. Even worse, I suspect that all the rare-earth mines currently in production would not provide sufficient output to provide all the magnets required for a U.S. or worldwide transition from gasoline power to electric cars, leading to shortages and sky high prices for magnets, motors, cars and a wide variety of industrial and consumer products.

I will concede that more rare-earth mines could be placed in operation, and even some in the U.S., but that creates another slew of contamination-related issues beyond the scope of this discussion.

It also gives foreign governments undue power to influence and blackmail the U.S. into submission, which undermines the rhetoric of fighting unfair competition and bringing industrial production back to the U.S. Maybe in order to buy the magnets we now have to purchase the complete EV from China.

Similar considerations hold true for lithium in the use of batteries, which is increasingly in short supply, but which is, once again, not the topic of this discussion. However, this issue remains for the availability of other raw materials such as copper, etc. where we also experience rapid price increases and shortages.

My personal opinion: rather than having a lot of ideologists in Washington, we may need some knowledgeable folks there who can really work through the technical aspects and feasibility and assess all the related implications. Wishful thinking can and will not remedy the climate issues.

Now let us move on: What are the implications? I remember back after the last recession when the availability of rare-earth magnets was restricted and prices shot up 1,000% and higher — manufacturers were hurting. One reason was the cost of their products increased, but more importantly, sometimes the magnets simply were not available. That was bad for the motor manufacturers, but it really helped consultants and small design companies that could offer alternatives.

One of these alternatives was the proliferation of internal permanent magnet (IPM) motors which had a high reluctance component, also referred to as PM-assisted reluctance motor. One of the designs I was involved with was a 60 KW traction motor that achieved wide operating range efficiency between 97.5% to over 98%, with only a small amount of rare-earth magnet materials. This efficiency had been validated by multiple dyno tests at different test locations and measured by independent consultants.

Similar results can be achieved if the rare-earth magnets are replaced with AC-8 ferrite magnets. There is at least one U.S. manufacturer left, but the U.S. has plenty of raw materials (mines) that can be ramped up quickly to provide U.S.-based magnets for such traction and industrial motors at a very beneficial cost infrastructure. Yet, little research is spent on advancing such motor designs, which opens up a potential magnet trap in the future. Ferrite magnet-based IPM motors can be one of the solutions to solve the pending magnet crisis, but it will require foresight and proactive R&D investments.

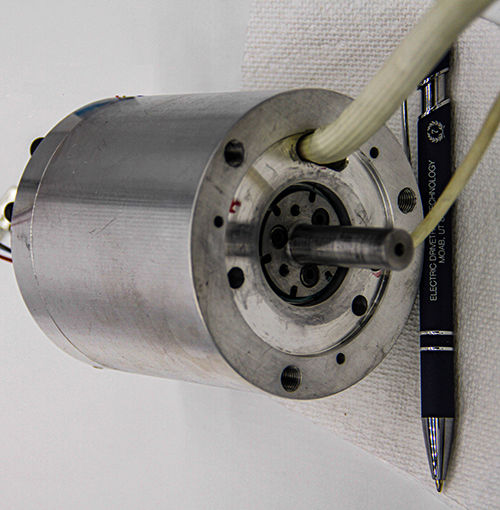

SYR pump => A 80mm diameter high efficiency 1.5KW pump motor

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.