The Advantages of Automatic Lubrication Systems

Atlanta Drive Systems examines grease vs. oils, single point vs. multi point strategies and the evolution of lubrication technology

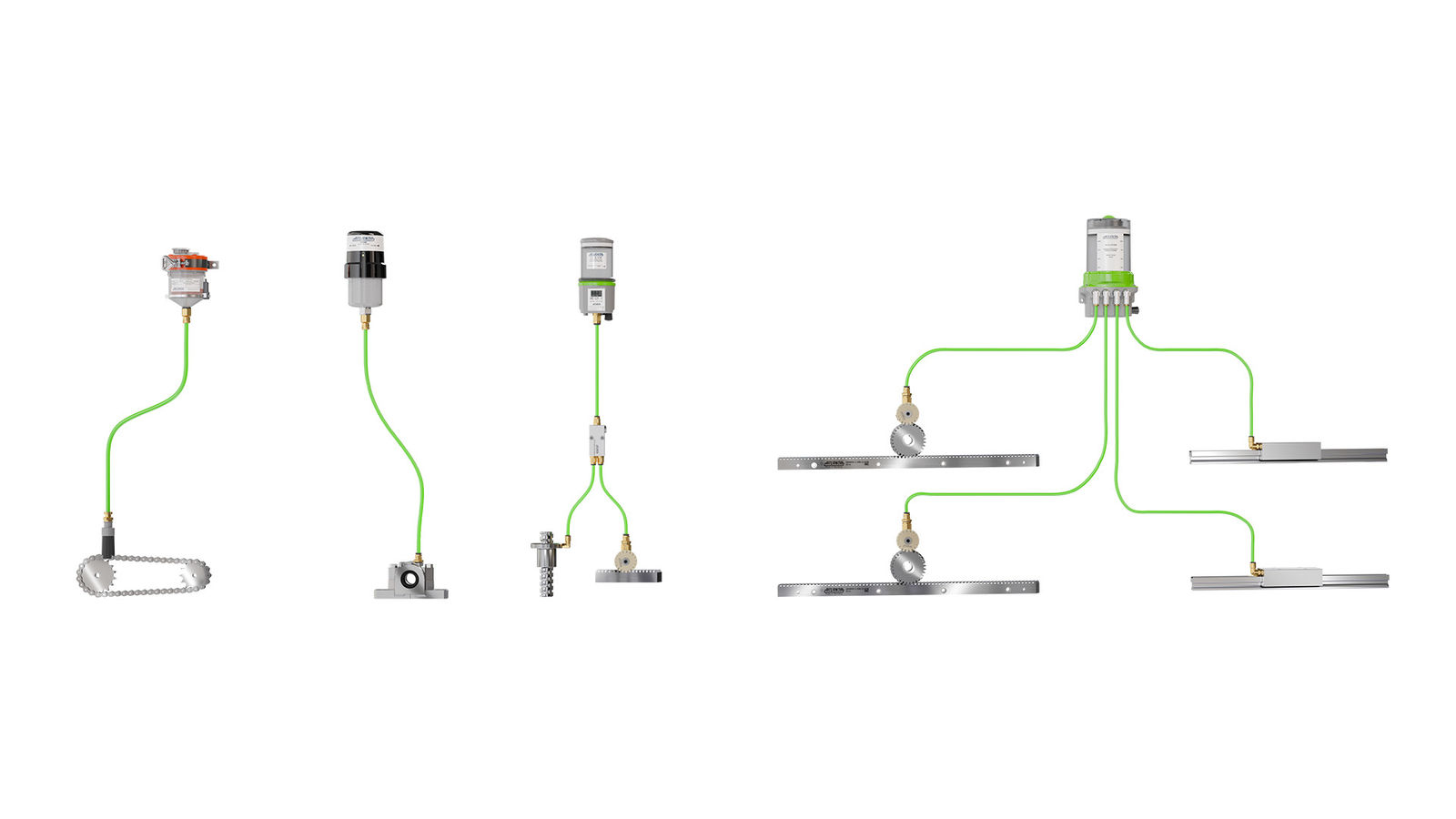

Whether single-point or multi-point lubrication, customers increase the performance of their machines and systems with a permanent and controlled supply of the necessary lubricant.

Atlanta Drive Systems, Inc., Farmingdale, NJ, offers rack and pinion systems, actuators, gearboxes, servo reducers and lubrication systems for many different industries including machine tool, automation, aerospace, woodworking, material handling, robotic, food, packaging, stone and special machinery. PTE recently discussed the company’s lubrication solutions with Peter Alfano, senior applications engineer.

Why is a reliable lubrication system so critical to open gearing applications?

Trustworthy and reliable lubrication systems are critical to ensure the life of open gearing primarily to prevent metal-on-metal contact. A proper layer of lubricant is required to reduce friction while increasing allowable loading and prevents premature wear of the contact surfaces. Lack of lubrication may result in loss of precision due to wear and the eventual failure of the gearing if it is not maintained.

Describe the differences between manual and automatic lubrication systems. What are the key advantages of an automatic lubrication system?

Manual application of lubricant can be effective in some cases, but it can be unreliable. The maintenance schedule of the system may not always coincide with when the system requires additional lubrication. This may result in messy over lubrication and other times of inadequate under lubrication. This is especially true if the location is difficult to access. Using an automatic system provides the advantage of a steady and uniform supply of lubricant. Automatic systems are typically sized with an appropriate volume to not require service for 12+ months.

How is lubrication technology evolving in manufacturing today?

Lubrication technology is evolving largely through dispensing methods. The automatic systems have changed from basic self-contained electro-chemical or electro-mechanical systems to more advanced versions featuring multiple outlets, multiple pumps and with PLC integration.

What do your lubrication experts recommend between selecting greases or oils? What are the advantages/disadvantages of both options?

We recommend NLGI 0 (very soft) or 00 (semi-fluid) grease. This consistency range works for many open gearing applications because of the balance between flowing freely through any accessory components for distribution while also staying in place once applied. Oils are not ideal for open gearing because they are more likely to flow resulting in more mess and positionally not enough surface coverage.