How can comprehensive condition monitoring optimize maintenance?

Schaeffler

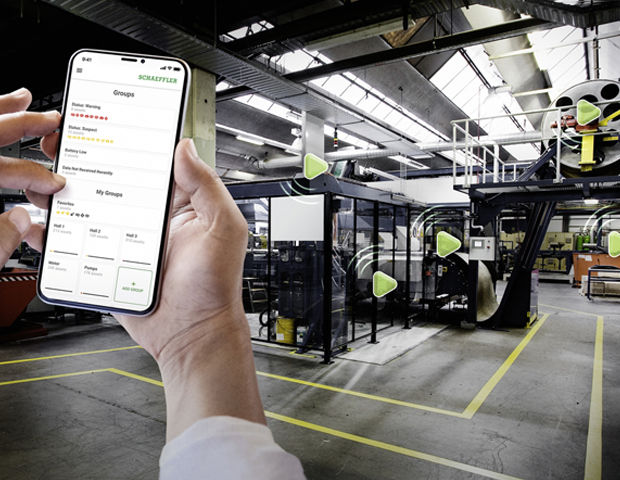

Despite the threat of high costs resulting from unplanned downtime, production facilities – especially balance of plant assets and supply systems – are not subjected to comprehensive and regular monitoring using modern condition monitoring tools. In most cases, comprehensive condition monitoring is not considered at all. Sometimes projects even fail during the “proof of concept” phase.

Despite the threat of high costs resulting from unplanned downtime, production facilities – especially balance of plant assets and supply systems – are not subjected to comprehensive and regular monitoring using modern condition monitoring tools. In most cases, comprehensive condition monitoring is not considered at all. Sometimes projects even fail during the “proof of concept” phase.

This white paper shows how comprehensive condition monitoring can work economically using new technologies. In fact, this can be accomplished with such ease that the entire maintenance team can use this solution without possessing any special prior knowledge.

To access this content, please give us a little more information about yourself: