'Roll-Slide Mini' Carriage and Rail Linear Motion Systems Now Available From LM76

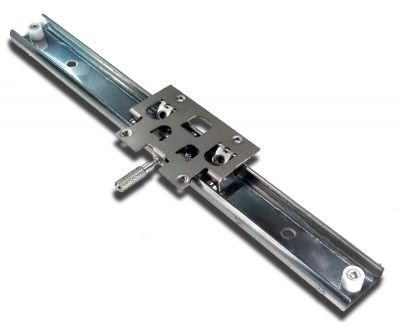

Low cost, "Roll-Slide Mini" carriage and rail linear motion systems are now available from LM76 in lengths from 160mm (6.30 in.) to 1200mm. Travel is from 88mm (3.46 in.) to 1128mm (44.41 in.)

These low profile linear motion systems are 12mm (0.47 in.) high and feature quiet running, low resonance, smooth motion, low friction 440c stainless steel roller bearings, low magnetic signature, corrosion resistant stainless steel rails and electrodeless nickel plated carriages.

The "Roll-Slide Mini" carriage and rail linear motion systems have evenly-spaced mounting holes in the rails and the carriage has four drilled and tapped mounting holes. The maximum load is 80 N (45 lbs) for a single carriage, and the temperature range is -10O to 50O C (-50 O to 140O F). Applications can include camera sliders, sensor carriers, medical, bio-pharmaceuticals, food, defense/aerospace, and manual adjustment mechanisms. As an option the carriage is available with a stainless steel, plastic tipped friction knurled hand stop, and the rails are supplied with end stops. Carriage and rail systems can be ordered with zero clearance for maximum precision.

LM76 manufacturers and distributes a broad variety of FDA & USDA compliant bearings and shafting, in inch sizes of .25 inches to 1.5 inches, and a FDA and SDA compliant profile rail and slide system that can be integrated into new and existing applications. The bearing options include self-lubricating FDA and USDA compliant self-lubricating (PTFE) composite bearings in a 304 stainless steel shell, and lower cost bearings with a ceramic coated shell and FDA and USDA compliant liner. Bearings are available in closed and open configurations, and are drop-in replacements for all inch sized linear ball bearings.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.