Reducing Plant Downtime

Win-911 Examines Critical Role of Remote Alarm Notification Software

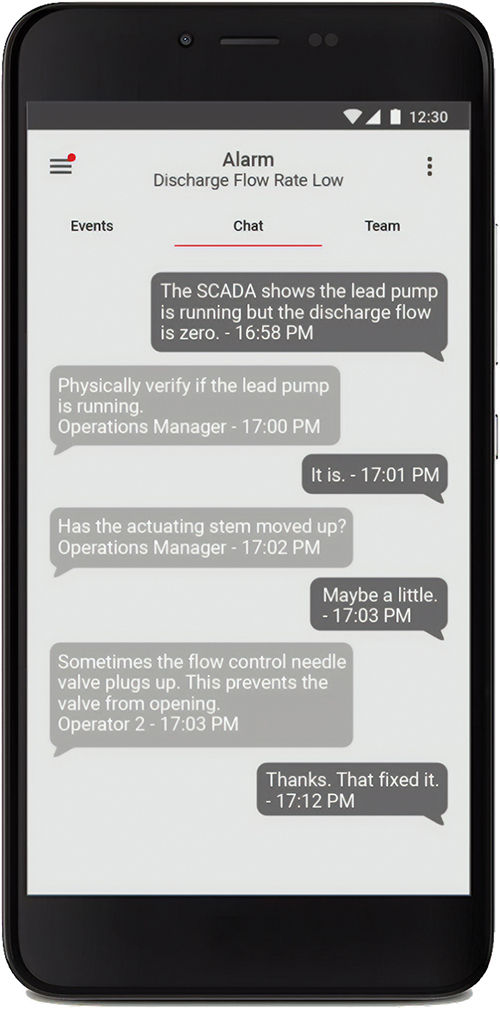

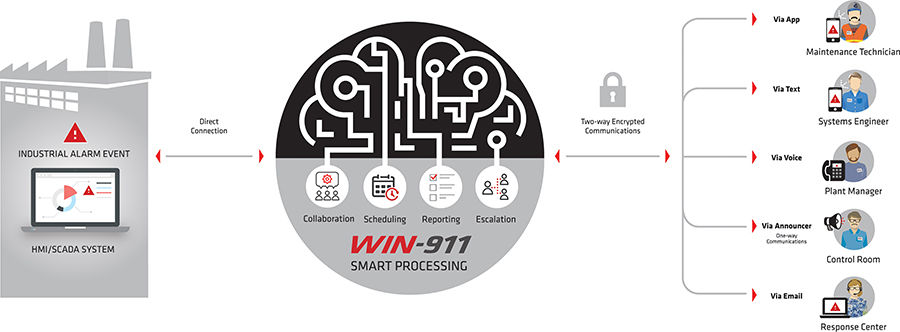

Moving from an automated plant to a smart factory is a leap forward but well worth the effort to enable a fully connected and flexible system - one that can use a constant stream of data from connected equipment and production systems to learn and adapt to new demands. (www.2deloitte.com) Manufacturing plants are facing a convergence of extreme challenges: an aging workforce coupled with the transfer of knowledge, increased demands for higher quality products utilizing fewer resources and the pandemic. Navigating these issues is critical to maintaining ongoing operations and controlling costs. If something additional happens, such as unplanned equipment downtime, the results can be a logistical nightmare and financial disaster. But it's certainly not all doom-and-gloom. Recent trends in IIoT, machine connectivity, and monitoring solutions are playing a critical role in mitigating unexpected problems and staffing challenges.

Manufacturing Workforce

U.S. manufacturing is in the thick of an expected shortage of two million workers between 2015–2025, according to a report from Deloitte and the Manufacturing Institute (Food Engineering). This has only been exacerbated by the pandemic. In the latest report by Deloitte and the Manufacturing Institute, as many as 2.1 million manufacturing jobs will be unfilled through 2030. The report warns the worker shortage will hurt revenue, production and could ultimately cost the US economy up to $1 trillion by 2030 (www.manufacturinginstitute.org). The study's dramatic findings come from online surveys of more than 800 U.S.-based manufacturing leaders, as well as interviews with executives across the industry and economic analyses.A 2017 industry study sponsored by Advanced Technology Services found that the leading cause of unscheduled downtime within respondents' facilities was aging equipment (42 percent), followed by operator error (19 percent) and lack of time needed to perform necessary maintenance (13 percent). Of all the core disciplines affected by the shortage of trained personnel, machine maintenance may be the most troublesome for manufacturing plants. Thirty-five percent of U.S. manufacturers are currently seeking maintenance technicians, and an even higher percentage are shifting at least some maintenance responsibilities to operating personnel—a potentially dangerous tactic at a time when equipment is becoming increasingly automated and complex.

According to the National Association of Manufacturers' outlook survey (www.nam.org) attracting and retaining a quality workforce constitutes one of the top challenges facing the manufacturing industry. This industry faced a labor shortage exacerbated by the aging of the [manufacturing] workforce and gradual retirement of the baby boomer generation—as of 2017, nearly one-quarter of the sector's workforce are age 55 or older. Additionally, 97 percent of respondents reported that they feared losing institutional knowledge when [older] workers depart. The study also examined the innovative approaches manufacturers can use to extend older workers' productivity and help transfer institutional knowledge to the next generation.

Manufacturing jobs are becoming more complex, including the maintenance of the hi-tech plant equipment. However, the answer to the labor shortage and transfer of knowledge may be rooted in additional technology.

Unplanned Downtime

Millions of dollars are invested each year in capital improvements to facilities and equipment to increase product safety, protect employees and reduce costs, which is important since equipment in a typical food processing plant, for example, may run 16 to 20 hours a day, every day—or even 24/7. Equipment failure is the most common cause for downtime. According to analyst firm Aberdeen Research, downtime costs manufacturing facilities an astounding $260,000 per hour (IIoT World). A Deloitte industry report cited recent studies that show unplanned downtime costs industrial manufacturers an estimated $50 billion annually. However, downtime can cost a company more than just money—it can be a logistical nightmare.

As the world continues to grapple with COVID-19 and supply chain issues, manufacturing plants are under more pressure than ever to maintain ongoing operations. However, given that maintenance worker shortages existed even before the pandemic, what can plants do to mitigate unplanned downtimes?

Sensors and SCADA

One strategy to help resolve this is for manufacturing plants to invest in technology for areas with worker shortages, such as sensors that monitor whether a machine is working properly instead of having someone possibly crawl under equipment to check out a problem.

Sensors pick up on performance aberrations that simply can't be detected through manual spot checks and personnel monitoring. By detecting the underpinnings of potential issues in real-time, sensors can alert maintenance teams of the need to investigate to prevent a machine failure before it happens.