In addition to stressing the quality of its products, Lee Linear is also getting more involved with each customer request, right from the initial planning period.

“Being privy to the application and knowing what’s involved can really help. We have a customer that’s a printing equipment manufacturer, and they’re constantly coming to us with new drawings and asking how we can help them drive out costs. We’ve been doing that for years and have a good relationship with them. Probably the only way U.S. manufacturing is going to be here 30 years from now is to work directly with the customers both early and often.”

Haveson stresses the importance of letting the customers know they are dealing with precision items, a crucial aspect in linear motion.

“You’ve got your low-end and high-end material, but you’re always going to look for something in the middle of the road that’s going to give you the most bang for your buck,” Haveson says. “I think as the technology grows, there’s going to be a need for more accuracy and longer life and customers will embrace the quality issue. They’ll realize spending more now will save them more money in the future.”

Customer-Driven Technology

Danaher Motion is better serving its customers with the creation of a unique, web-based sizing and selection tool. Linear Motioneering allows users to optimize machine design and operations in just a few simple steps.

“The program basically allows users to input loads, select the accuracies you need and the life and the environment it would operate in,” says Pete Castelli, engineering manager at Danaher. We’ll output a solution set that generates a part number, a price, downloads a model or drawing and gets a quote for the customer.”

Created in 2007, Linear Motioneering is now public for the systems division. Its success in linear motion slides has prompted Danaher to create similar programs for other divisions.

This automatic boxcar painter uses bearings from Lee Linear.

“We’re now coming to a point where customers will be able to use this technology for gearboxes, shafting and ballscrews,” Castelli says. “It’s a real innovative tool for those who aren’t sure what direction they need to go when they originally visit the website.”

Castelli notes that customization is becoming the underlining theme in linear motion.

“We’re seeing a lot of price pressure and it drives you to do some value engineering,” Castelli says. “The applications in linear motion are becoming much more specialized, and from the engineering side, it’s just a little more resource-intense. We’re much more heavily involved in customization.”

Castelli thinks many companies are pulling back to their core expertise and customers are no longer looking for off-the-shelf items.

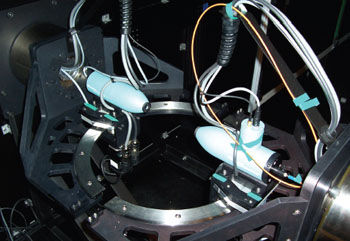

The QT Clamp Extrusion from Bishop-Wisecarver is currently being installed in its first application.

“They want a linear motion company to come in and customize the application; we’re seeing this in the medical industry right now. Engineers want to make sure the right people are working on each new job.”

The outlook for linear motion products at Danaher has been a bit of a juggling act. Castelli says that they have seen some decline in the packaging and manufacturing fields and some incredible uptick in the medical and semiconductor industries.

“There’s some growth in areas we didn’t expect and some decline in other areas. Our goal is to make sure our customer base knows it’s a linear motion assembly that we’re selling and this sizing and selection tool is a great focal point.”

Ease of Installation

Bishop-Wisecarver has several wheel and track sizes to accommodate its linear motion assembly for packaging, small shops and other manufacturing markets. A key factor in its success is that the systems can handle harsh environments.

“Our product is insensitive to contamination,” says Nigel Watson, engineering manager at Bishop-Wisecarver. “It has a self-cleaning mode of operation and we’ve always been recognized for our overall quality in this department.”

Watson, like many others in linear motion, is fighting a battle against cost-conscious customers in 2008. Many customers need a system designed for a specific load, and cost is definitely a factor.

Photo courtesy of Bishop-Wisecarver.

“Our customers are not only looking for good performance, but they’re also looking for high value. We’re combating this with a new product that offers to use our standard wheels and track with a low-cost installation, an installation our customers can provide,” Watson says.

The product in question will be featured at the Bishop-Wisecarver booth at IMTS 2008 as well as the International Woodworking Fair (IWF) 2008. Watson explains that the concept will eliminate the use of fasteners to the rails by securing the track using an aluminum clamp.

“These clamps can lend themselves to any extrusion. You have to tailor the clamp to the slot size. We’re looking to do a full range of these in the near future,” Watson says.

With responsibilities in the applications, mechanical engineering and quality departments, Watson’s very familiar with what is being designed and innovated, and he oversees much of the development.

“Our customers are very aware of our product lines and I think the small size of our company allows us to be very flexible with their various demands,” Watson says. “While the growth isn’t great in linear motion right now, it’s definitely a time when we’re looking at our systems and responding to our customer’s needs. This will certainly help the revenue stream as we go forward.”

For More Information

Bishop-Wisecarver

2104 Martin Way

Pittsburg, CA 94565

Phone: (925) 439-8272

Fax: (925) 439-5931

www.bwc.com

Danaher Motion

Thomson Systems

761 Koehler Ave.

Ronkonkoma, NY 11779

Phone: (631) 467-9814

Fax: (631) 467-9814

www.danahermotion.com

Lee Linear

727 South Avenue

Piscataway, NJ 08854

Phone: (732) 752-5200

Fax: (732) 968-7080

www.leelinear.com