Mitsubishi Electric Robot at the Cutting Edge of Cake Slicing

When automation OEM Newtech looked to design a new ultrasonic cutting machine for the bakery industry, it turned to Mitsubishi Electric for a fast, efficient, flexible and clean robotic solution. The result is an innovative machine design that can cut cakes to the highest levels of precision, working flexibly for different portion sizes and quantities, and eliminating problems of damaged product.

Based in Bedford, Newtech is a specialist supplier of standard machines which provides today’s food manufacturers with cost-effective, high quality automation systems, with the highest levels of flexibility to meet ever-changing market demands. One of the company’s innovations is the adoption of ultrasonic cutting technology, giving best-available cut quality for products which are difficult to process using conventional methods.

Cakes, in particular, are notoriously difficult to cut reliably: machines tend to be time consuming to set up for different cake sizes, depths and portion numbers, whilst traditional cutting technologies can result in uneven, messy cuts and unacceptable levels of damaged product.

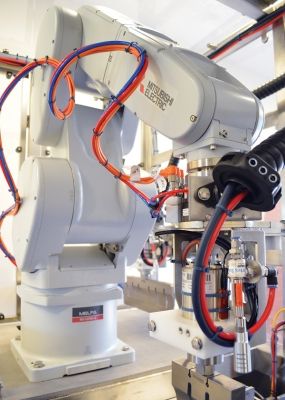

With a new machine design, Newtech set out to overcome these limitations by combining ultrasonic cutting with robotic actuation of the cutting blade. For an out-of-the-box solution which would be easy to integrate into the machine, Newtech turned to Mitsubishi Electric. The solution offered by Mitsubishi Electric was built around an RF13 13kg payload, six axis robot, mounted within a stainless steel cell. One of the fastest robots in its class, the RF13 is also highly dextrous, being capable of reaching all the way behind itself and also very close to its base, giving a highly flexible and compact working area.

The robot is controlled via the Mitsubishi Electric MELSEC iQ Platform.The iQ Platform is a multi-functional automation environment which incorporates Q series PLC control and uniquely, an integrated robot controller within the same rack. This removes the need for a network connection to a traditional external robot controller, which means that communication exchange between the PLC CPU and the robot controller is handled across the rack, increasing speed, data throughput and reducing robot setup times.

A CC-Link network is used to connect other machine control components such as a Mitsubishi Electric inverter drive and a dedicated Mitsubishi Electric WS safety controller providing a totally integrated machine control solution. A Mitsubishi Electric GOT2000 HMI provides a user interface where operators can select different cake recipes and set parameters such as product height, portion size, total number of portions and trim size. The GOT HMI also acts as a teach pendant for the robot via dedicated screen templates within the HMI.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.