Mechatronic Subassemblies for Factory Automation

Mechatronic Subassemblies for Factory Automation

Three trends to consider in 2021

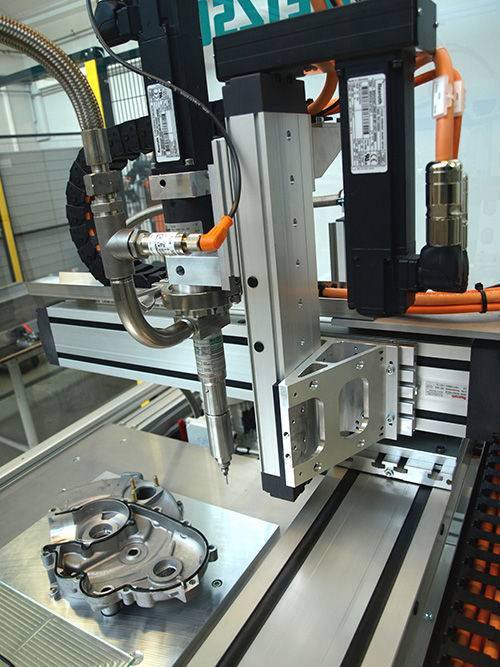

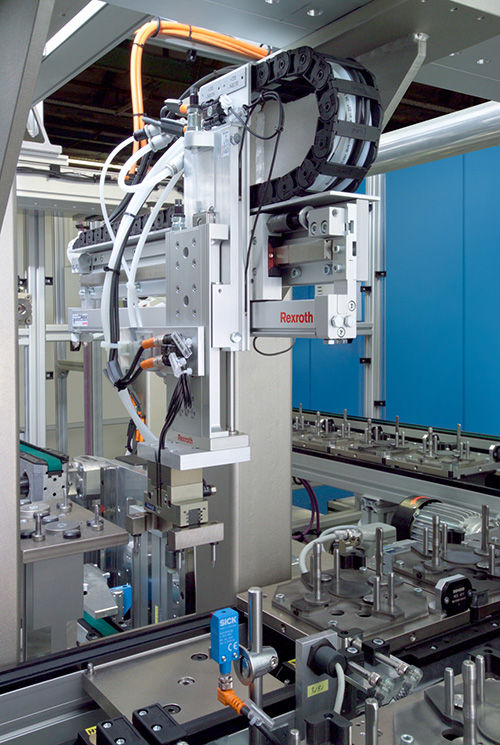

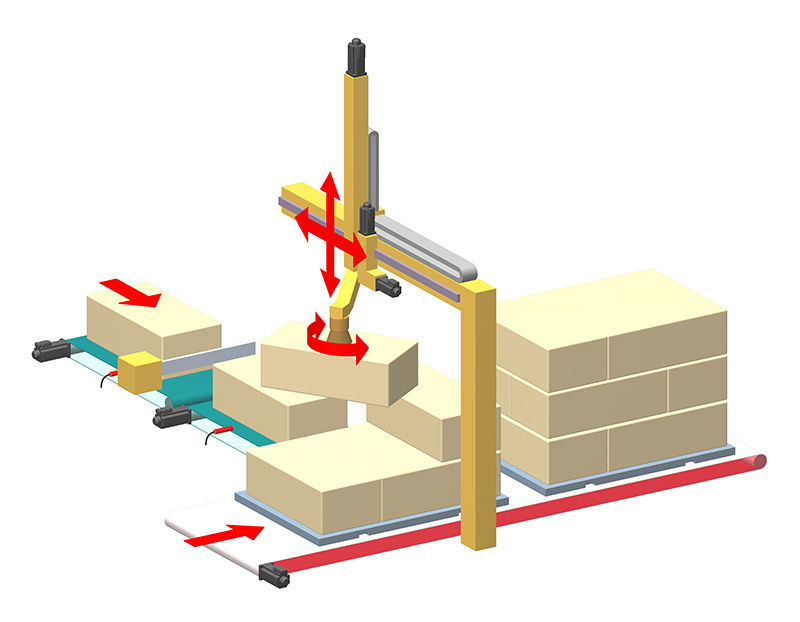

Fully integrated mechatronic subassemblies provide versatile and cost-effective solutions for factory automation applications. These pre-engineered mechatronic subassemblies are an essential component of today's high-speed and high-precision automation. Cartesian robots provide simple, robust and readily available multi-axis motion. Utilizing complete solutions, including linear components, servo motors, controls and sensors, makes it easier and faster for machine builders to bring the overall complex manufacturing system for demanding industries to market.

Industry Trends in Machine Building

Constant pressure to improve both the cost-efficiency and the flexibility of the machines they build and use is driving increasing numbers of original equipment manufacturers (OEMs) and end-users to seek suppliers that can deliver integrated solutions versus committing their own resources to engineer and develop solutions. There are several key industry factors driving this movement.

- OEMs and end-users are focusing on core competencies: OEMs that build highly specialized machines realize the value of concentrating engineering resources on optimizing the performance of their machines' core functions. This makes it more attractive to outsource the creation of the machines' subsidiary motion functions to suppliers with proven expertise in these areas.

- Integration of control and mechanical functions: Machine builders and users alike are recognizing the benefits of approaching motion technologies as a single discipline. Adopting a method that combines multiple technologies into complete subassembly solutions delivers economies of scale and design advantages.

- Next-generation engineers: Recent engineering graduates may be more inclined towards the use of integrated subassemblies compared to their predecessors due to engineering roles becoming more demanding in ever-increasingly lean-running companies.

- Retrofitting existing production lines: To meet the demand for customization and Industry 4.0 capabilities, manufacturers are retrofitting existing production lines. Using subassemblies equipped with open engineering control interfaces that can communicate with existing systems, regardless of programming language, makes it easier to facilitate these transitions.

- Supplier consolidation: Rather than relying on multitudes of suppliers, engineering staff and purchasing agents are seeking one source to engineer, integrate and supply as many components as possible into complete solutions.

- Globalization of the end-user: Global supply chain dispersal causes many manufacturers to require OEMs to support their products, from engineering through delivery and long-term maintenance, in locations throughout the globe.

Applications for Subassemblies

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.