Mayr Introduces New Generation of ROBA Topstop

Gravity-loaded axes in robotics applications must be safe. At the SPS 2025 in Nuremberg, Mayr Power Transmission showed the new generation of ROBA topstop safety brakes make this possible in smart environments. The compatible ROBA brake-checker module enables permanent brake monitoring. Combined with the ROBA gateway, the system delivers valuable data for proactive machine maintenance, a digital twin, and smart production environments. In addition, a practical checklist supports brake validation.

For production facilities or robots with gravity-loaded axes, the protection of people and material is of the essence. Safety brakes built according to the fail-safe principle – i.e., applied in de-energized condition – provide the foundation here. The ROBA topstop from Mayr Power Transmission holds the loads in position reliably and prevents uncontrolled movements in case of power outages or emergency stops. As they are placed between the motor and the output, the brakes can be retrofitted in existing constructions – a solution that reduces effort and costs.

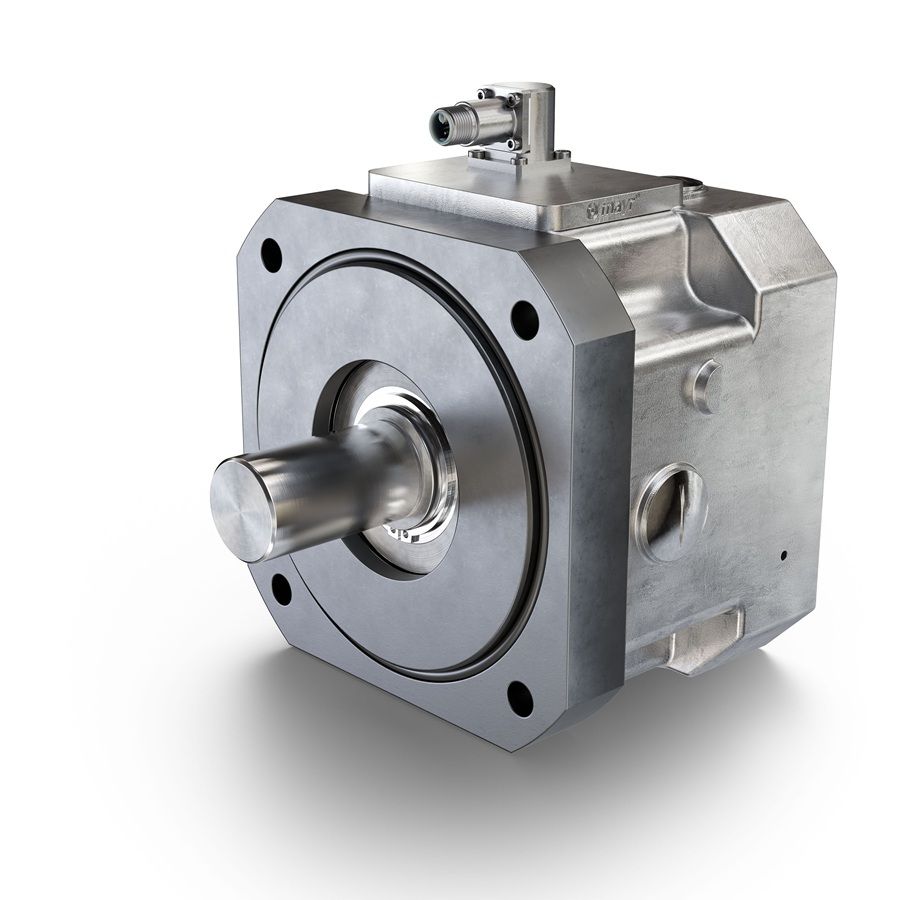

Robust construction ensures reliability

For day-to-day industrial operations, the ROBA topstop braking system is equipped as an independent, compact module. O-rings at the interfaces ensure reliable sealing against dust and moisture – the brakes achieve IP66 protection as standard. The vertical axes remain secured even when the drive is dismantled, which is advantageous during maintenance and transport. Thanks to the adaptable flange dimensions, the system can be easily integrated into existing constructions.

Sensorless monitoring – data for smart production

With the ROBA brake-checker, Mayr offers a module that monitors the safety brakes without the need for additional sensors. It recognizes the brake’s condition based on current and voltage trends, enabling proactive maintenance. Critical parameters – such as switching time, coil temperature, and functional reserves – are reliably detected. The additional ROBA gateway module renders the solution network compatible so that the collected data can be integrated into existing remote maintenance systems or digital twins can be created, for example, thus ensuring smart production and more transparency in the drive line.