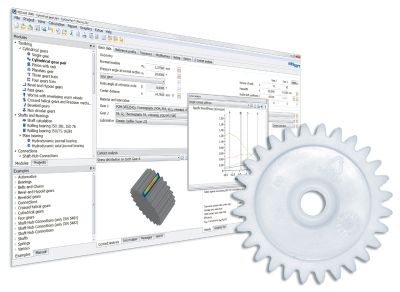

KISSsoft VDI 2736 Receives New Supplement for Calculating Plastic Crossed Helical Gear Deformation and Wear

The application area of plastic gears has grown significantly in the last decade. The requirements from the industry to design stronger, lighter, quieter and more efficient gears have also motivated plastic manufacturers to produce custom made materials.

In the last two years, the new VDI 2736 guideline for the design of plastic gears was introduced. Unfortunately, its material data for lifetime calculations is limited. In order to design gears with custom made materials, it seems necessary to measure the fatigue data and temperatures in gear tests prior to the gear design. If you are interested in this topic, a KISSsoft paper (see link below) presents an accelerated testing procedure for plastic gears that is based on different levels of testing. As a supplement to the VDI 2736 guideline, the calculation of plastic deformation and wear of plastic crossed helical gears (according to Pech) has been implemented in the KISSsoft Release 03/2016.