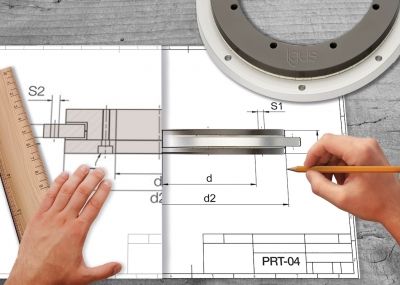

Igus Slewing Ring Bearing Offers Reduced Size and Weight

Igus has developed a maintenance-free and wear-resistant slewing ring bearing for medium loads that also offers significantly reduced weight and space.

The new bearing is 50 percent smaller in installation height, 60 percent lighter and can save users up to 20 percent in costs. The bearing will be particularly effective in automation, stage technology and control panels.

Igus, whose headquarters are in Cologne, Germany, runs its North American operations out of Providence, R.I.

Extremely demanding applications

High cycle rates and loads in welding systems, indexing tables or the packaging industry, are extremely demanding for slewing rings. In order to withstand this, Igus has been offering slide-supported slewing ring bearings for 15 years.

The iglide polymer slewing ring bearings (PRT) have sliding elements between the inner and outer bearing rings made of aluminum or stainless steel. The maintenance-free sliding elements made of high-performance iglide J plastic ensure that friction and wear are minimized without lubrication. The high-performance plastic withstands a maximum surface pressure of 35 MPa. In addition, Igus has FDA and ESD-compliant versions with no minimum order quantity.