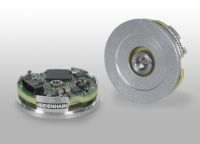

Heidenhain Offers Sturdy Rotary Encoder

In robotics and automation technology, rotary encoders and resolvers serve on servo drives as feedback systems for position and speed control. An increasing number of applications require multiturn versions of absolute encoders that are low in cost and as sturdy as resolvers, but with features beyond what resolvers can provide. Heidenhain's new EBI 1135 absolute inductive rotary encoder fits this bill. Within the new EBI 1135, the fast EnDat 2.2 pure serial interface is used for transmission of a high-resolution absolute position value to improve transmission reliability, in particular in environments with high electromagnetic noise potential (e.g. on welding robots). With an overall length of less than 13 mm and a housing outside diameter of only 37 mm, the EBI 1135 is one of the world's smallest rotary encoders and is therefore predestined for use on highly dynamic servomotors with small dimensions for automation technology and industrial robots. The encoder attains a total resolution of 34 bits (singleturn: 18 bits, multiturn: 16 bits). Its modular design without ball bearing and a battery-buffered revolution counter permit very compact dimensions. The new EBI 1135 rotary encoder distinguishes itself in particular with optimized inductive scanning together with a sturdy design. This becomes possible in particular because it functions without optical components (glass scale, LED), which can be handicapped by contamination, vibration, shock and high temperature. The higher permissible axial scanning gap tolerance of ± 0.3 mm, the expanded voltage range of 3.6 to 14 V and, compared with multiturn scanning with a mechanical transmission, the greatly expanded multiturn value range of 65-536 distinguishable revolutions increase the reserves in the application available to the customer.