Dontyne Systems Honored for Best Practices by the UK Parliament

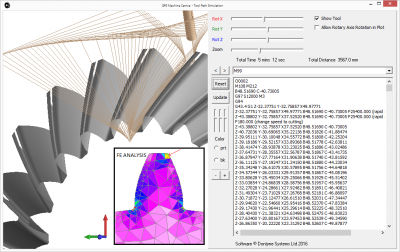

Dontyne Systems applies Industry 4.0 principles to rejuvenate ancient technology. In 2006, Dontyne Systems created the Gear Production Suite software program to provide a platform for integrating design and manufacturing processes for more efficient production. The export and import of data to machine tools and measuring devices was essential to reduce potential errors.

Dontyne Gears was formed by Dr. Mike Fish in 2013 to address a requirement in the gear industry to facilitate small testing programs for large and small specialist companies. This would utilize all modern techniques for both CAD and production equipment as well as provide a testing program if necessary.

Since its inception, Dontyne has associated itself with recognized industrial institutions such as the British Gear Association (BGA) and the American Gear Manufacturers Association (AGMA), thus ensuring consistency in its calculations.

Dr.Fish and Dr.Palmer also contribute to several ISO committees relevant to gear production and have represented the UK at these meetings on occasion. Dontyne feels this is important not only for consistency but also to drive development of these standards with new developments. The developments can be shaped by results from Dontyne testing programs but also from research and development centers within the UK.

Dontyne is partnered with Design Unit (DU), Advanced Manufacturing Research Center (AMRC), and Advanced Forming Research Center (AFRC) – very valuable assets to the UK, which keep Britain at the forefront of the mechanical power transmission industry. To read more about how the company was recently named a UK Best Practice, visit the website below.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.