Buyer's Guide

Company Profile

Contact Information

Contact: Stan Porter

Title: New Business Development

Phone: (513) 868-0900

Fax: (513) 868-2105

Email: Click here to see email.

Website: http://www.forcecontrol.com

Location

Force Control

3660 Dixie Highway

Fairfield OH 45014

Clutch Brakes, Motor Brakes, Tension Brakes, and Dynamometers

Clutch Brakes, Motor Brakes, Tension Brakes, and Dynamometers Force Control Industries, Inc. manufacturer's superior quality, unique design industrial clutches and brakes. Based on oil shear technology our industrial clutch and brake products provide superior life, as well as smooth operation, and quick response.

CLUTCH BRAKES

Posidyne Clutch Brakes with Oil Shear Technology are designed to provide start stop indexing for high cycle, severe duty applications where high reliability is critical and downtime very costly. Allowing the motor to run continuously provides high cycle capability up to 300 CPM, improves efficiency, eliminates inrush current, reduces cyclic inertia by not cycling the motor armature, and reduces maintenance costs.

POSIDYNE CLUTCH BRAKES SIZE 2-30 FOR SEVERE DUTY, HIGH CYCLE APPLICATIONS

POSIDYNE CLUTCH BRAKES SIZE 2-30 FOR SEVERE DUTY, HIGH CYCLE APPLICATIONS- Torque: 518 Lb. Ins. to 79,000 Lb. Ins.

- HP: 1 HP to 1500 HP.

- Air or Hydraulic actuation

- Cooling: Basic, Fan, Water, and Forced Lube

- Optional C-Face or Piggyback Available

- Wash Down, Marine Duty, Hazardous Duty

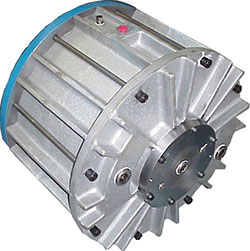

POSIDYNE SIZE 1.5 CLUTCH BRAKE WITH LIGHTWEIGHT HOUSING

POSIDYNE SIZE 1.5 CLUTCH BRAKE WITH LIGHTWEIGHT HOUSING - Torque 427 Lb. Ins. 5 HP

- Air or Hydraulic actuation

- Cooling: Basic

- C Face Fits NEMA 56 to 184T motor frames

- Optional Foot Mounting Available

- Wash Down, Marine Duty, Hazardous Duty

POSIDYNE X-CLASS C-FACE CLUTCH BRAKES

Value Engineered for OEM Applications

Value Engineered for OEM Applications- Torque: 90 to 1,000 Lb. Ins. of torque. 1 – 25 Hp

- Fits NEMA 56 to 215 motor frames.

- Air or hydraulic actuation.

- Optional input shaft and feet available.

- Wash Down, Marine Duty, Hazardous Duty

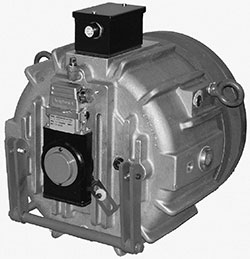

MagnaShear Electric Release Spring Set Motor Brakes

Designed with Oil Shear Technology the MagnaShear Motor Brakes typically mount to the back of a brakeless brake motor. They are designed to be a stopping brake, not just a holding brake.

They can survive the harsh environments of mining, manufacturing, material handling as well as packaging and food processing with minimal maintenance and no adjustment. The totally enclosed rugged housings keep dirt and moisture out while reducing noise and extracting heat.

- Torque 6 Lb. Ft. to 1250 Lb. Ft.

- Fits NEMA Frame 56 to 440 motor frames.

- Spring Set – Electric Release

- IEC and Custom available

- Clamped-Split-Quill saves motor shaft and keyway

- Crane Duty, Marine Duty, and Hazardous Duty Available

- Manual Release, lock out, and released indicator available

- Optional Encoder for VFD Applications

- Can also be furnished as an assembled brake motor.

POSISTOP AIR SET/SPRING SET MOTOR AND COUPLER BRAKES

The Posistop Motor and Coupler Brakes are designed for long life with minimal maintenance in severe and critical applications. They are typically furnished as spring set, pressure release brakes however pressure set spring release is available in some models. The multiple disc design reduces inertia of the brake reducing load on the motor and improves efficiency each cycle.

Posistop motor brakes are designed to mount to the back of brake motors, and the coupler brakes are designed to mount to the drive end of the motor, often between the motor and reducer. Coupler brakes can also be used on servo motors.

- Torque 6 Lb. Ft. to 2,030 Lb. Ft.

- Fit NEMA 56 to 449T motor frames

- Spring Set - Pressure Release

- Pressure Set—Spring Release

- IEC and Custom flange available

- Wash Down or Marine Duty

- Severe and Hazardous Duty

- Assembled brake motor OPTION

- Thru Shaft Version Available

THE POSISTOP® X CLASS OIL SHEAR MOTOR AND COUPLER BRAKES

The Posistop® X Class Oil Shear Motor and Coupler Brakes are designed and tested to operate over 20 million trouble free cycles with only occasional oil changes and no adjustment - ever! This is a true dynamic stopping brake, not just a holding brake.

This unheard of life expectancy allows the Posistop® X Class Motor and Coupler Brakes to be used on applications previously thought impossible to do using a brake. Dust, dirt, or moisture is no problem.

Smooth running, quiet engagement, and many options such as vertical, horizontal, foot mounting kit, extended input shaft, manifold mounted valve to name a few.

The Posistop X Class Brake is a direct replacement for many Nexen, and Warner brakes used in packaging, food processing, and production machine applications.

- Torque 6 Lb. Ft. to 2,030 Lb. Ft.

- Fit NEMA 56 to 449T motor frames

- Spring Set - Pressure Release

- Pressure Set—Spring Release

- IEC and Custom flange available

- Wash Down or Marine Duty

- Severe and Hazardous Duty

- Can be furnished as an assembled brake motor

- Can be installed on customer’s motor

POSITORQ BRAKES FOR TENSION CONTROL

The Positorq Oil Shear Absorber brakes are a unique design for continuous tension control. The unique Oil Shear Technology provides extremely smooth, ultra-quick response, negligible wear with no adjustment required, high energy dissipation in a compact package, and noise free. Positorq Brakes are rated up to 180,000 Lb. Ft. Slip Torque and 3000 Thermal Horsepower.

The Positorq brakes work well in tension applications especially unwind stands where the brake is used to maintain tension on the strip. This can be paper, board, plastic, copper, steel, and wire. The brake can be coupled, flange mounted, or connected through gear, belt, or chain drive.

- Steel strip, paper, wire, plastic, cardboard

- 50 Lb. Ft. to 180,000 Lb. Ft. Continuous Tension

- Thermal Dissipation Up to 3000 Thermal HP.

- Linear Torque Control

- Quick Response – Smooth Quiet Operation

- Dynamic Stopping Capability for Set or E-Stop

POSITORQ DYNAMOMETER LOAD BRAKES

Whether it’s testing the most complex aircraft system, off road final drives, or tractor transmissions; Force Control has the products for your load testing requirements. Our patented high-torque, low-speed Positorq load brakes are used to simulate real world environments.

Force Control Industries unique Oil Shear Technology provides heat dissipation for high horsepower applications while maintaining a compact profile capable of direct mounting to the drive axle - eliminating additional gearboxes.

- Quick Response

- Proportional Linear Torque Control

- Continuous High Torque at Low Speed

- High Static Torque

- No Chatter Down to 0 RPM

- Quiet—Less Than 20 dB

- Compact Size—Direct Axle Mount