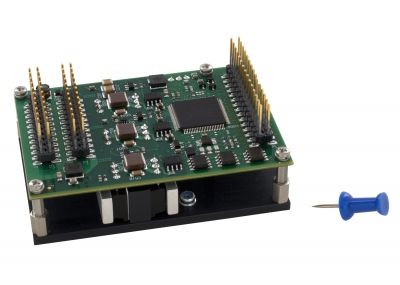

Data Device Corporation Introduces BLDC Motor Controller

Data Device Corporation (DDC) introduces a high performance DSP based family of programmable, turnkey motor controllers designed to precisely control the position, torque, and speed of 3-phase BLDC motors, with maximum reliability. The high power density 80V/30A rated MC-5000 series BLDC motor controller operates over an extended -40°C to +105°C temperature range, and is available in configurations to support motors that utilize a Hall sensor for torque and speed control, or absolute PWM and incremental encoder feedback for position control. The device is fully configurable through the provided CANopen control interface, and can be programmed, via an easy-to-use Graphical User Interface (GUI), enabling it to deliver optimal motor performance with a wide variety of brushless DC motors and loads. Additionally, ease of programmability reduces time-to-market costs and in-house development efforts by enabling key system parameters to be tuned to optimize performance during development, and then, if needed, reprogrammed for use with additional applications and motors. Beyond these cost and time saving benefits, the MC-5000’s compact, highly-efficient single-module design provides size, weight, power and cost savings by combining control and power amplification into a single solution, minimizing output losses and eliminating the need for a second printed circuit board and interface. The precision motion control performance of the MC-5000 makes it an ideal solution for single axis, point-of-load industrial applications, including: pump control, electric actuators, electric valve control, fuel pumps, industrial robotics, antenna/camera position control, unmanned vehicle electric drives and thrusters, autonomous guided vehicles, and medical diagnostics control. “DDC’s new MC-5000 torque, speed and position motor controllers offer the ideal combination of high performance, power saving efficiency, and programming flexibility, making them the ideal plug-and-play solution for high-reliability applications with limited space,” stated Michael Agic, DDC’s product line manager.