With condition monitoring, drive and status data are recorded periodically or continuously to optimize the operational safety and efficiency of machines and plants. Important information can be derived from the data analysis to proactively maintain systems, reduce downtime, and increase the efficiency of the entire plant.

- Early detection and avoidance of undesired operating conditions

- Avoidance of unplanned downtimes

- Time-based maintenance is replaced by status-based maintenance

- Machinery and plant downtimes can be planned based on drive and process data

- Reduction of service and material costs

- Longer service life of components and machines

- Increased system availability

nsd tupH Sealed Surface Conversion System

This patented solution is not paint; it’s a chromate-free chemical process that changes the physical properties of NORD’s aluminum housings, creating a surface that is up to seven times harder than the original aluminum. After the process is complete, the housing receives an additional sealant that is resistant to contact corrosion from acids and alkalis (entire pH range), will not flake, and will not propagate damage when impacted or scratched. This solution is ideal for harsh environments involving chemicals or wash downs, and where sanitation and cleanliness are the highest priority.

- Conforms to FDA Title 21 CFR 175.300

- Lightweight compared to stainless steel

- Does not flake or chip like paint

- No penetration of corrosion, even if damaged

- Cost-effective alternative to stainless steel

- Easy-to-clean surfaces

nord.com

Festo—

#N-6213 (North Building)

Meeting the degree of protection IP65/67 for factory digitalization, the decentralized IO system CPX-AP-I allows compact and lightweight I/O modules as well as the decentralized valve terminals from Festo to be integrated into major host systems in a flexible and scalable way. Another advantage of CPX-AP-I is its seamless connectivity from the field level right through to the cloud, providing access to features such as predictive maintenance. This makes digitalization incredibly easy.

CPX-AP-I lets users from the general machine building, automotive or electronic sectors transmit their machines' process data in real-time. Up to 500 participants can be connected to the main systems with a cable length of up to 50 m between the modules. The benefit is that existing valve terminals from Festo can be easily integrated into the new system, so that nothing changes in terms of the pneumatic control sequence. An aspect that is forward-looking but already a reality is the system's connection to the IoT gateway CPX-IOT from Festo, enabling status data to be exchanged in cloud systems.

This all-rounder among remote IO systems is equipped with IO-Link technology as well as IO-Link device tool, simplifies commissioning without the need for additional software tools, and has a plug-in for the Festo Automation Suite and for using a web server, all tailored to each customer's needs.

The system is designed for applications in which installation space, decentralization, and digitalization are key. Based on the new AP system communication from Festo, CPX-AP-I ensures fast and seamless communication in all common host environments. This gives users a machine design that meets the requirements of the digital factory of the future.

festo.com

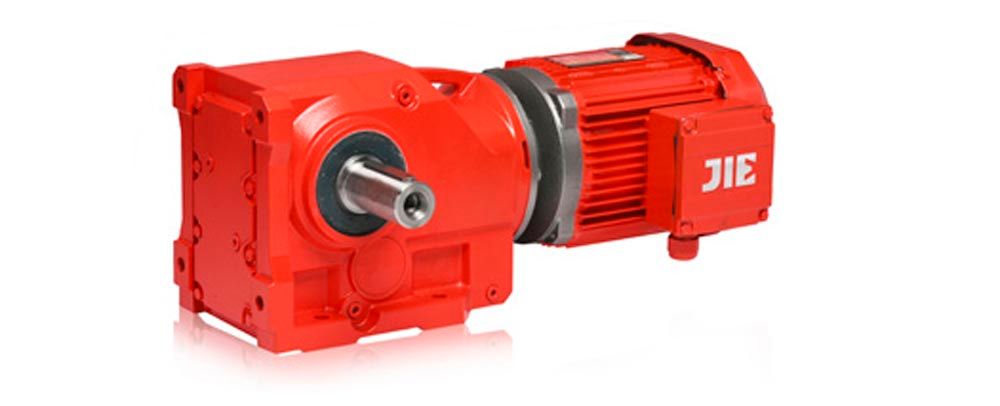

JIE USA, INC.—

#LU-7512 (Lakeside Upper)

Established in 1988, JIE produces gearmotors and reducers that serve the needs of their business partners through reliable designs and supply. Their ISO 9001 certified factories employ more than 650 people and produce over 800,000 units annually. From their US headquarters in Chicago, JIE offers a variety of gearmotor options that can be assembled in custom configurations and with short lead times from their extensive inventory of finished and component parts.

The JRTK helical bevel gearmotor is part of the JRT series of gearmotors from JIE.

The JRT series of inline helical (JRTR), helical bevel (JRTK), helical worm (JRTS), and parallel shaft (JRTF) gearmotors can be configured with NEMA, IEC, or servomotor inputs. This series allows JIE to quickly provide interchangeable solutions to the marketplace. The whole series comprises AD-type solid shaft, AM-type IEC motor, AQS-type servomotor, and AN-type input interfaces; solid shaft, spline hollow shaft, locking disc, and flange output modules; and foot, flange, and torque-arm installation. This product supports the modular combination and integration of multistage gearboxes with different types of adapters.

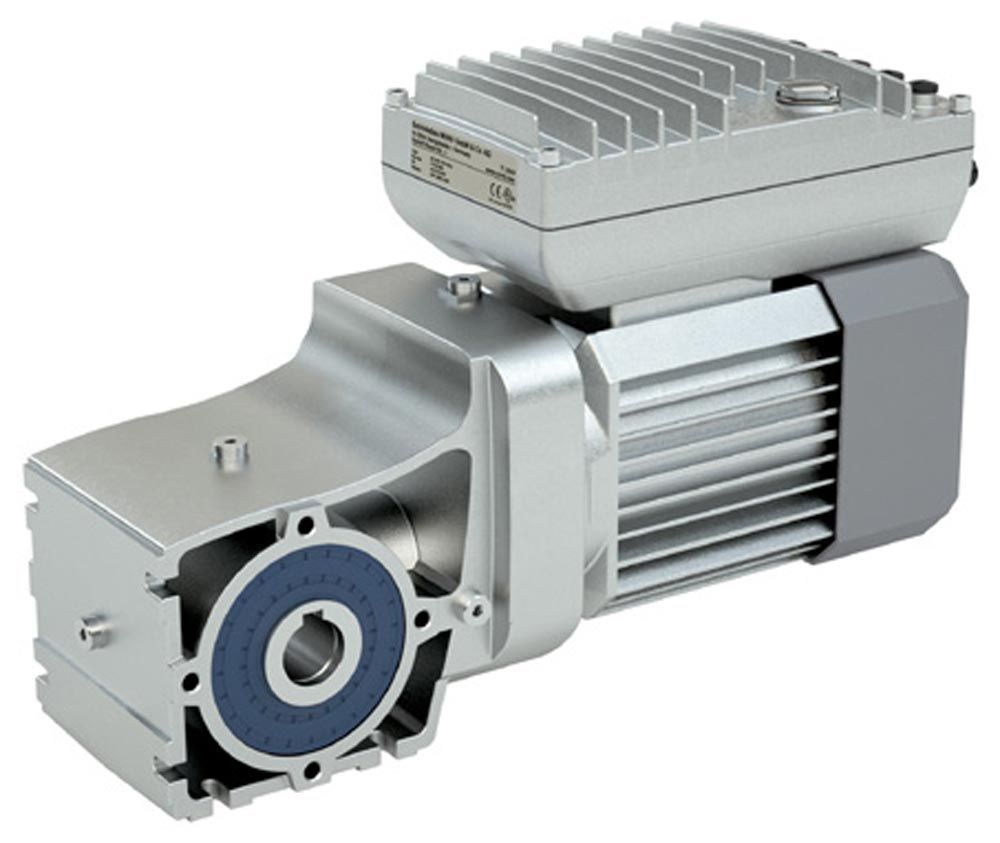

The JRWND series worm reducer, like all of JIE’s solutions, follows the concept of modular design.

The JRWND series of worm reducers offer customers fast access to universally adaptable solutions with various input and output configurations. Applied in printing and dyeing machinery, machine tools, textile machinery, automation equipment and other industries.

The JRE series of stainless-steel motors and gearmotors provide IP69K protection and are available in a wide range of gearing styles from worm to helical bevel, all from stock at JIE headquarters. JIE stocks NEMA motors in both aluminum and stainless-steel construction from ¼ hp–10 hp. The stainless steel gearmotors are useful wherever machines and systems are subject to particularly intensive cleaning.

Regardless of whether the gearmotors are used for materials handling, intralogistics or hygienic applications, their hygienic properties, long operating life and maintenance friendliness make them optimally suited to the specific production conditions in the food and beverage industry, pharmaceutical industry, and permanently wet environments.

jie-drives.com

IKO International—

#N-6069 (North Building)

Cam Followers

IKO cam followers feature exceptional rigidity, high load capacity, easy mounting, and excellent rotational performance thanks to an optimized design for outer ring revolution. IKO offers a comprehensive lineup of products that fit a wide range of industrial applications such as robotics, electronic parts production, and office automation equipment. We also offer two unique technologies: ThrustDisk and ThrustDisk Seals—a synthetic resin thrust washer that handles axial loads with exceptional wear and heat resistance—and C-Lube options, either built-in or as an attachment that provides long-lasting, maintenance-free operation. IKO also carries a large inventory of off-the-shelf cam follower products stocked in multiple U.S. locations to ensure delay-free availability and worry-free ordering.

ML Series Linear Guides

IKO ML Series ball-type linear motion rolling guides feature stainless steel construction as standard. The series also comes standard with C-Lube—a self-lubricating system with a built-in capillary element to provide long-lasting maintenance-free operation and cost savings. ML Series guides also provide stable accuracy and rigidity—even if your application presents variable load directions and sizes, or complex loads.

Crossed Roller Bearings

IKO Crossed Roller Bearings are designed with rollers alternately crossed at right angles to each other between inner and outer rings. This arrangement creates greater roller contact with the raceways, allowing the bearings to take radial, thrust and moment loads from any direction at the same time with less deflection under load. IKO Crossed Roller Bearings also come in a variety of styles to meet the needs for varied applications including robotics, medical, semiconductor and food and beverage to name a few.

ikont.com

JW Winco—

#LU-8249 (Lakeside Upper)

Longtime exhibitor at Pack Expo International, JW Winco, is a leading supplier of standard industrial machine components and assembly hardware for the industrial and commercial equipment industries, including OEMs, packaging, medical equipment, automation, and more. JW Winco also specializes in offering value-added services to engineering, purchasing, and maintenance departments.

This year, JW Winco will feature their hygienic design (HD) family of products, along with their standard parts made of detectable plastics, and standard parts with antibacterial surfaces. They offer a comprehensive selection of metal and plastic, metric and inch size standard machine components, hand-operating, and assembly hardware.

Standard parts are extremely versatile in their application. Increased use of standard parts greatly reduces the costs of product development and in turn, provides the engineer with more time to devote to larger project requirements. The engineers can concentrate on the actual machine or equipment design, as standard parts can cost-effectively be procured externally.

All standard parts of the HD product family combine high surface quality, freedom from dead spaces, nonscooped outer surfaces, and sealed bolting areas. A sealing concept based on FEM calculations ensures reliable contact pressure after installation. HD also means that the time and material needed for regular cleaning are significantly reduced—which also noticeably lowers operating costs.

JW Winco’s HD product family continues to grow, which includes knobs, U-handles, hand levers, indexing plungers, latches, cover sleeves, leveling feet, screws, and more.

Standard parts with visual detectability are made of light blue plastic making them especially visible to the human eye and, perhaps more important, to optical monitoring systems. Especially in milk, dairy, and meat products, but also in most other areas of food production, blue colors are rarely encountered and therefore stand out well.

Metal detectable standard parts are made of dark blue plastics that contain additives such as iron oxide. As a result, they are detected by metal detectors as of a particle volume of 0.125 cm³, meaning that even hidden plastic chips can be detected. Also, the metal detectable plastic standard parts are made of FDA-compliant plastic granulate as per FDA CFR.21 and EU 10/2011. The plastic can therefore be used safely in contact with food and in pharmaceutical production.

The antibacterial standard parts of the Sanline product family can prevent bacteria and germs from propagating on an operating element, actively reducing their spread and preventing bacterial illnesses that could otherwise result.

Two different active principles can be found in the Sanline product family: Plastic standard parts with additives based on silver ions and metal standard parts with a powder coating based on zinc molybdate. Both principles destroy the cell walls of the microorganisms, causing them to die. The antibacterial effectiveness is retained for a long time, even after frequent cleaning cycles, and is safe for the user.

jwwinco.com

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.