Ball Bearing Inner Ring Fits and Creep (Part 2)

Figure1—Differential hub cracking on high load test due to wear of material from insufficient press fit.

Welcome back to Part 2 of our inner ring and creep discussion. We left off with our creep calculation resulting in a 10.5 µm minimum inner ring fit to avoid creep. For the sake of making clean dimensions, let’s call it 10 µm on the lower end and the upper end is simply whatever your manufacturer can hold. For the 6205, something around 20–25 µm tolerance range would be expected. Often this can be accomplished with hard turning alone. Surface finish is not too critical here. Most bearing manufacturers will recommend a 0.8 Ra for small bearings and 1.6 Ra for large bearings, without clearly defining what a large bearing is. The main consideration for surface roughness is that if the surface is too rough, the peaks of the material will plow off during the bearing press resulting in less of a press fit than intended.

Figure 2—NSK Rolling Bearings E1102k c.19.

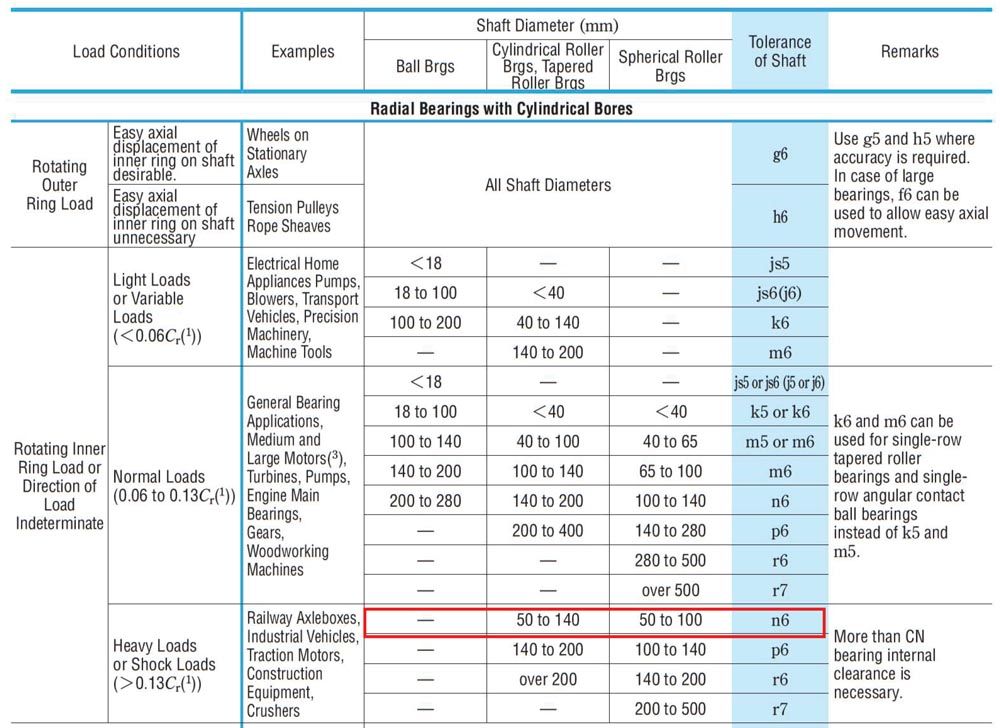

Now we consider our shaft tolerance range of 10–20 µm. If we review the standard shaft fit chart in Figure 2, we see that this custom range falls between m6 and n6.

If we review our standard fit table in Figure 3, you will notice on the load condition column that a Heavy Load is defined as > 13 percent of the dynamic load rating Cr. We have designed our creep loads for 50 percent of Cr, so falling near the n6 range makes perfect sense. Applying these fits is very easy. The 6205 inner ring bearing tolerance is 25 0/-0.010 mm. Bearings are usually written in negative unilateral tolerances like this. The nominal diameter (what we call it by), 25 mm is the largest diameter. We size our shaft by taking the bearing nominal bearing diameter and applying the fit tolerances. Our shaft diameter is simply 25.01–25.03 mm.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.