Desktop Belt Drive Services with Gates

Software platform provides end-to-end mobile troubleshooting and file management capabilities.

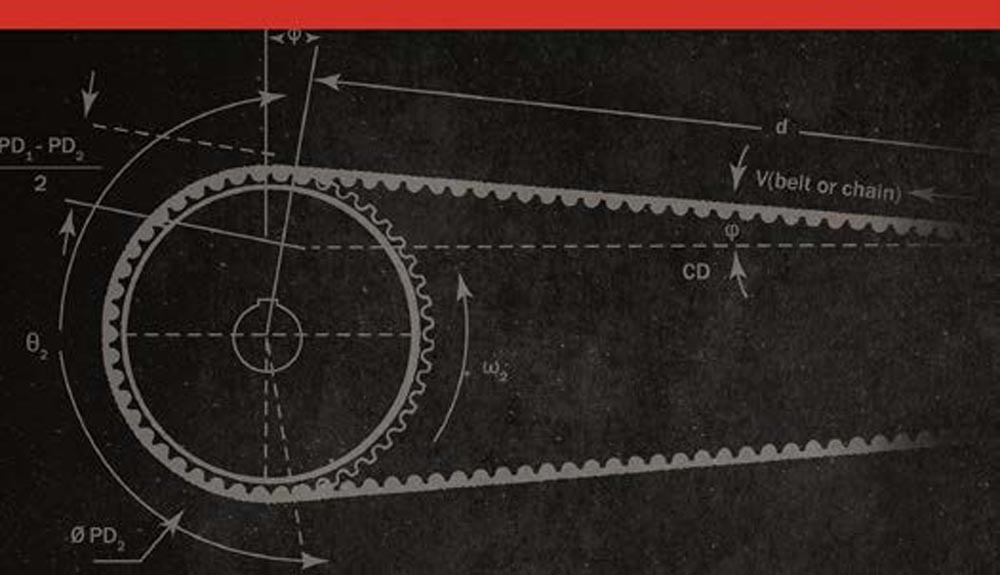

If you have ever installed a belt drive, you know the process can be time-consuming and frustrating, and installation is only half the battle. And if you have ever specked-out a belt drive on-site with a customer or supervisor watching, you know it can be worse than parallel parking a semi-truck on Main Street. Understanding our customers’ challenges is what inspired us to develop our latest belt drive software solutions: Gates Design Power and Gates Design Power Mobile. These two platforms combine unique functionality to provide an end-to-end solution that can help from basic troubleshooting and site surveys to full site chain-to-belt replacement and create your most complex power transmission (PT) design applications.

What Is Design Power?

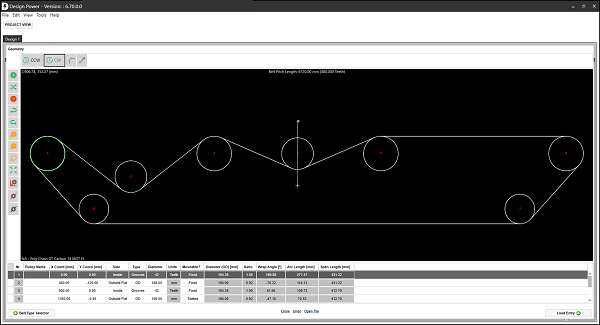

Design Power is a desktop application that combines the best of Gates PT design services into one easy-to-use software package to support the engineering and specification of belt-drive systems. Simply put, it helps you select the right belt-drive components to create the design quickly, easily, and properly. Gates Design Power features updated and upgraded versions of Gates Design IQ and Design Flex Pro applications. In addition to the user-friendly functionality of each specialized design module, Design Power leverages a state-of-the-art knowledge library with design guidance and sophisticated belt performance models. Automatic syncing with the Gates catalog streamlines and empowers the design process with direct access to the latest products, specifications, and ratings.

Design Power also adds new organizational features with digital collaboration tools, such as holding multiple designs in a single project file, tracking design derivatives, and iterations, and noting who made what changes along the way. Best of all, it is completely free and regularly updated.

Gates Design Power features updated and upgraded versions of Gates Design IQ and Design Flex Pro.

Gates Design Power features updated and upgraded versions of Gates Design IQ and Design Flex Pro.

Why a Mobile App?

In April 2023, combined the best of the desktop version with extra features to assist our users while in the field. Gone are the days of keeping track of paperwork after documenting the details of the drives that need to be converted. Simply download the Design Power Mobile app to use the Distance Measurement tool and the Flashlight RPM Meter to estimate the center distance and speed of your belt drive to identify the right specifications. Then, after installation of the new belt, measure the noise reduction percentage using the built-in Sound Meter and turn on the Sonic Tension Meter in the app to ensure proper belt tension on the spot. With Design Power Mobile, you can do all these tasks with increased safety since using internal mobile device functions eliminates the need to place your hands on the drive itself.

Finally, the details of each facility’s drives can be stored in the most highly touted feature of the Design Power Mobile app: Facility Management. With the Facility Management tool, design reports are separated by facility and location, and users can set up replacement reminders and record service dates. The extended support tools of this mobile app allow for a full evaluation of each drive on-site to help ensure no additional follow-up work later in the process.

How Do the Mobile App Modules Work Together?

We created an end-to-end support solution for the people we serve. Putting ourselves in the shoes of inside sales, outside sales, customers, and field engineers, we considered the example of a Power Transmission (PT) site survey to demonstrate the efficiency and effectiveness of Design Power modules working in harmony.

There are many factors to consider in a chain-to-belt (C2B) or belt-to-belt (B2B) conversion. Will belts work as well as chains? What kind of new technology is out there to support this conversion? How much money can I save over time? Who will help me understand the new products and assist with the actual installation of the new drive? Are V-belts still the best option, or would a synchronous belt be better for my application? In all these situations, adding Design Power to Gates user’s tool kit makes the process even more efficient.

Imagine doing a full survey of the drives at a facility. Normally, you would walk through the full site with several sheets of paper, a pen, and several different measurement tools. All the drives would need to be shut off for safety, creating downtime in production or requiring the evaluator to begin working after hours. Design Power allows you to keep all drives running while completing the site survey during normal business hours - with minimal interruption to daily tasks and carrying only a tablet or phone.

As an example of the simplicity of the Design Power application, one begins the site survey by creating a new entry for their facility, keying the details right into the Facility Management tool on their mobile device, and hitting save. From there, start the walk-around with the maintenance repair team or Gates representative. As belt-drive replacement or conversion opportunities are identified, enter the details into Design Flex Pro. This tool generates solutions meeting all predetermined requirements and prioritizing cost-effectiveness. Select the best option for the site and then click to add that option to the facility entry. All the inputs and possible solutions are reliably stored for future reference or changes. At any point in the process, one can add more people as facility managers, allowing them to view and collaborate on the project using the information gathered during the original survey. On installation day, users rely on the Facility Management tool to access key drive details like recommended tension specifications and part numbers and store details like install dates and tension for future reference. Using built-in app modules, such as the Sonic Tension Meter and the Sound Level Meter, directly from Facility Management allows the ability to streamline data collection and instantly store it within the specific drive entry. Through this process, all team members can take advantage of the maintenance and replacement reminders to avoid unplanned downtime and keep things organized.

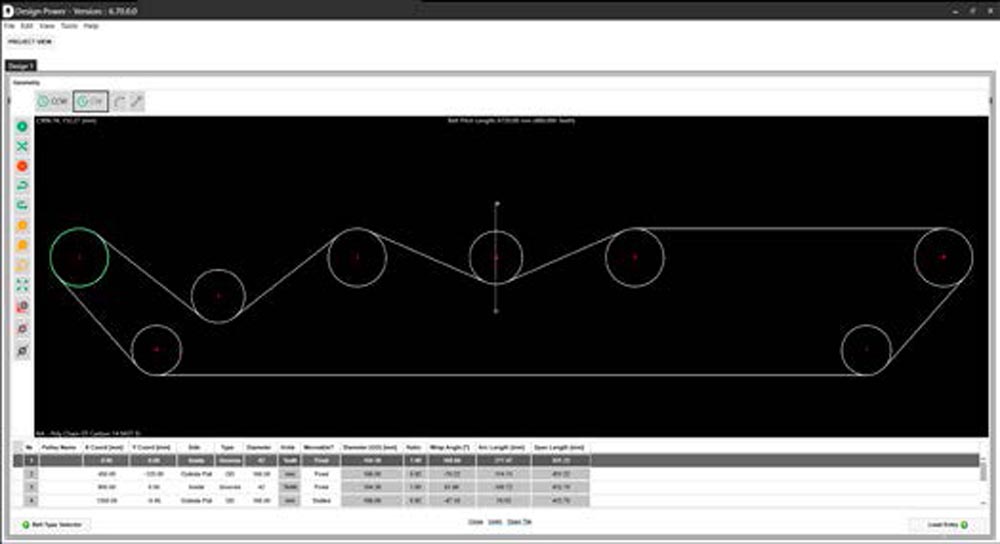

Design Power offers new organizational features with digital collaboration tools, such as holding multiple designs in a single project file, tracking design derivatives, and iterations, and noting who made what changes along the way.

Design Power offers new organizational features with digital collaboration tools, such as holding multiple designs in a single project file, tracking design derivatives, and iterations, and noting who made what changes along the way.

So, Why Did Gates Create Design Power for Multiple Platforms?

Gates created Design Power to give users maximum flexibility - plain and simple. The mobile and desktop versions provide access to our valuable tools on your devices, and we even offer a web version with no software installation required, extending access to any user and any device with a web browser. Thanks to our modern software architecture, all three platforms utilize the same back-end data and calculations, ensuring consistent experiences and results. Data is stored in the cloud, so facilities, designs, and most settings link to your account and are available across platforms.

Related Articles

-

April 2, 2024

-

2024 Trends in Fluid Power

March 1, 2024 -

-

-

Easy Integration

April 2, 2024

-

-

Easy Integration

April 2, 2024 -

The Flexible Factory

April 2, 2024