OES Offers Three-Axis Gimbal Mounts with Motor Options

The Azimuth and Angular Elevation Stages of the AU270-AER incorporate high precision 200 mm diameter rotary stages, and the Roll Stage is 100 mm in diameter.

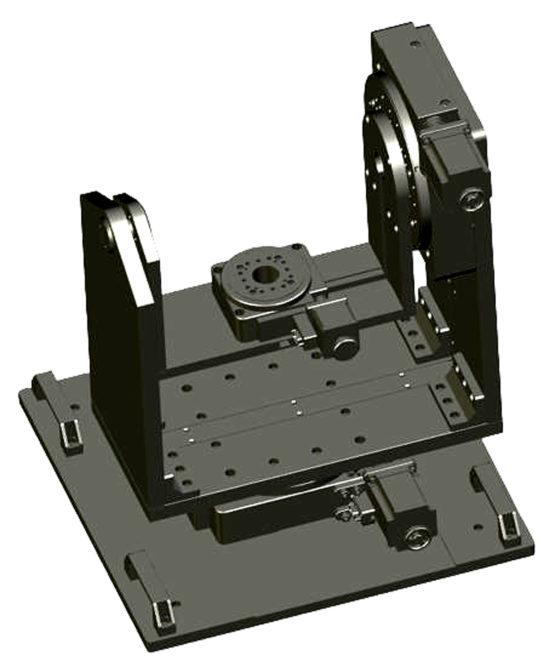

OES (Optimal Engineering Systems, Inc.) has released four all new Three-axis Azimuth, Angular Elevation, and Roll Gimbal Mounts. These new high precision and high stability AU270-AER Gimbal Mounts locate the surface of the Roll Stage 115 mm below the center line of rotation allowing for the positioning of: Cameras, optics, lasers and instrumentation for scanning, tracking, positioning, pointing, and other applications on their respective centerlines.

The Azimuth and Angular Elevation Stages of the AU270-AER incorporate high precision 200 mm diameter rotary stages, and the Roll Stage is 100 mm in diameter. The Roll Stage has a precision pattern of threaded holes for mounting tooling, cameras, lasers, etc. and a through hole for cables and optics. Each stage features V-groove and crossed roller bearings, capable of 360 degrees of continuous rotation and driven by a 180:1 worm gear. Motor options to power each stage include: Two Phase Stepper Motors (AU270-AER-01), Three Phase Brushless Servo Motors with Quadrature Incremental Optical Encoders (AU270-AER-02), DC Servo Motors with Quadrature Incremental Optical Encoders (AU270-AER-03), or Two Phase Stepper Motors with Quadrature Incremental Optical Encoders for position verification (AU270-AER-04). Electrical connections are made using 9 pin DB-9 connectors.

The resolution of each stage is 0.001 degree or 3.6 arcsec with 10 micro-steps per Step Motor Driver in use. Higher resolutions and travel speeds to 45 degrees per second are possible with the servo motor options.

The total height of the AU270-AER Three Axis Gimbal Mount is 539 mm, and the Rotary stage has 270 mm of clearance. The Azimuth stage is mounted on an optional 450 mm x 450 mm aluminum plate with four handles and mounting holes for increased stability. The total weight of the gimbal stage is 45 kg. These Three-axis Gimbal Mounts can be ordered as a complete plug-and-play system with a multi-axis motion controller, joystick, trackball, or keypad.