Always Fit to Print

What would a trade magazine be without a healthy low-ratio, high-speed gearing system?

Print is not dead. While reading magazines cover-to-cover is a lost art—thanks to work responsibilities, 24-hour sports/entertainment coverage, and the universal time suck known as Instagram—someone, somewhere still prefers the printed word to the shiny, unfriendly artificial light of tablets and smartphones.

This publication (hopefully) provides information engineers can discuss, debate, or collaborate on for future manufacturing endeavors. There would be no words, no photographs, no advertising without the paper used to print this very magazine.

At the heart of paper mill production is the large industrial gearbox, a component that rarely gets the credit it wholeheartedly deserves for providing the right amount of torque, reduction ratios and overall efficiency gains to keep paper mills moving. The very same gearboxes that appear in PTE case studies, technical articles and product news items could be responsible for the paper this magazine is printed on.

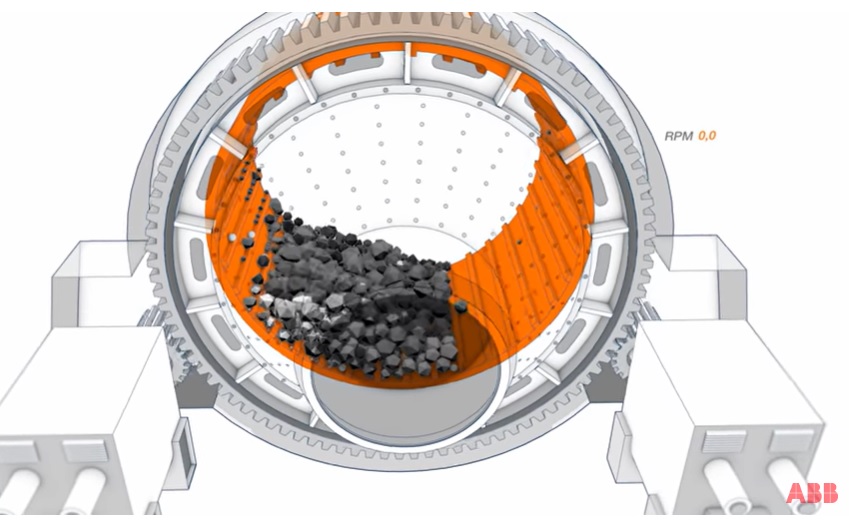

The papermaking process starts by grinding wooden chips or other fibrous material into pulp. Paper mills in North America, Europe and Asia go through forming, pressing, drying, and calendaring processes to create some 400 million tons of paper every year.

Gearbox providers are tasked with maintaining the equipment for pulpers, paper machines, and vacuum pumps. These gearboxes help convert logs into building material, turn barking drums, and provide the low-ratio, high-speed gearing needed between low- and high-pressure stage compressors. They are also essential in paper recycling efforts.

Valmet, headquartered in Espoo, Finland, for example, is a supplier of process technologies, automation and services for the pulp, paper, and energy industries. The company has more than 220 years of industrial experience, cooperating with customers in more than 700 board machine and 900 paper machine deliveries worldwide.

Paper production at Valmet includes complicated machines with dryers, siphons, motors, and ventilation systems that produce paper around 3,200 feet per minute. Operating conditions are typically unkind, offering hot, dusty, grimy, and wet conditions requiring consistent machine maintenance.

There’s a global field engineering team tasked with troubleshooting these gearboxes. Annual inspection visits to paper mills can become “Agatha Christie” mysteries as engineers attempt to figure out what killed the gearbox and how they can make it right to avoid plant downtime. Miraculously, these engineers can sometimes rebuild or repurpose a gearbox in one day to keep the paper rolling across the assembly line.

According to paper machine supplier Voith, the modern paper mill uses an efficient and complex series of processes and control technology for papermaking. The company is working to create the most sustainable manufacturing solutions by focusing on water management and reducing fiber consumption.

Ultimately, the technophiles of the world sometimes forget the engineering that goes into something as simple as producing a blank sheet of paper. And the manufacturing/engineering community continues to innovate paper production lines for the future to create maintenance-free, eco-friendly products.

“Our annual statistics are proof of the resilience of this industry and its unique attributes,” said Jori Ringman, director general of the Confederation of the European Paper Industries. “The pulp and paper sector remains in a leading position for its recycling performance, use of renewable energy, energy efficiency and sustainable sourcing. These are key to our capacity to develop rapidly in new markets.”

Furthermore, books and magazines just smell better, it’s a scientific fact!

Long live Print!