Bosch Rexroth Introduces Gearboxes for Electric Motors

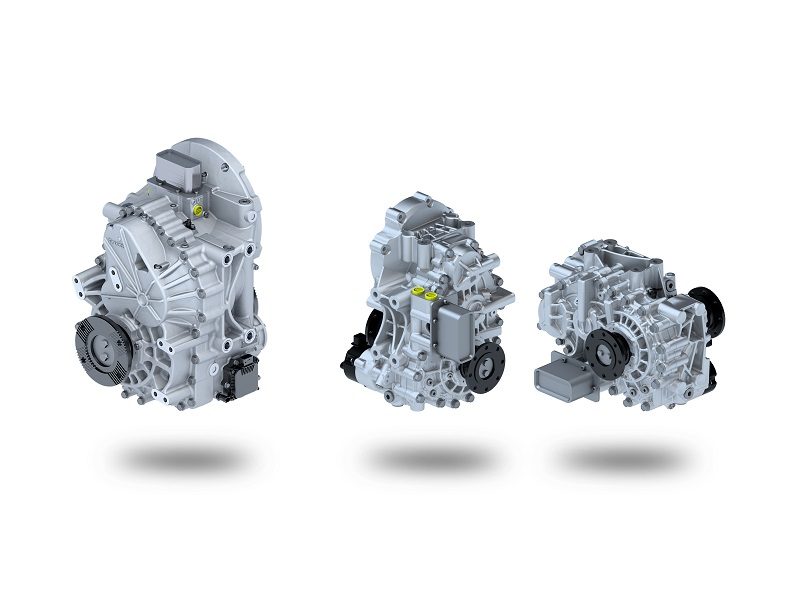

The compact Rexroth eLION gearboxes for the electrification of mobile machines are available in a 2- speed version (eGFZ 9200, left) and in a 1-speed version (eGFZ 9100) for a wide range of applications. (Image source: Bosch Rexroth AG)

As part of its new, extensive eLION platform for the electrification of mobile working machines, Bosch Rexroth has developed spur gearboxes which vehicle manufacturers can use to unlock the full potential of new electric motors. The one and two-speed gearboxes are installed in the central section of the vehicle and pool the energy in order to drive up to two axles with just one motor. The clever integration of essential components is evidence of the wealth of practical know-how that was drawn on throughout the development process.

The off-highway market is constantly evolving. Mobile working machines are becoming increasingly efficient. At the same time, exhaust gas and noise emissions need to be reduced. Machine manufacturers from all sectors recognize that electric drives are an important building block for a future-viable, sustainable product portfolio. In order to support and drive the electrification of off-highway machines, Bosch Rexroth has developed the first two axle drives designed especially for electric motors.

Flexibility for designing new drives

The 1-speed spur gearbox (eGFZ 9100) and the 2-speed shift gearbox (eGFZ 9200) are installed in the central section of the vehicle and therefore open up a range of new options compared to previous approaches with individual wheel drives. Both gearboxes enable high power densities to be achieved while simultaneously ensuring noise optimization for high-speed electric motors such as the Rexroth EMS1H and the Bosch SMG, but also for motors of other manufacturers with similar power.

Channeling high rotational speeds in the right direction(s)

Permanent-magnet synchronous motors are famed for being compact and highly efficient. However, their high rotational speeds present real challenges in terms of noise emissions, temperature, impermeability and splines. The eGFZ 9100 and the eGFZ 9200 have been specially developed for these applications. They also enable the power to be directed to one or both of the vehicle’s axles. For all-wheel drive, there is also the option to connect or disconnect an axle. A lockable center differential is also provided for permanent all-wheel drive.

Incorporating new technology into existing concepts

When integrating the gearboxes into the installation space available and into the machine concept, Bosch Rexroth drew on the knowledge and experience gained from fulfilling requirements for previous drives. Gearboxes not only have to be compact and reliable but also easy to integrate. While the 1-speed gearbox (eGFZ 9100) can be installed horizontally or vertically depending on the relevant requirements, both Rexroth series feature a Plug and Drive system. Components such as the heat exchanger and oil pump available in the gearboxes enable both gearboxes to be seamlessly integrated into the existing cooling circuit of the electric drive. Even the sensors for monitoring functions are already integrated into the gearboxes and can be adapted to suit a wide variety of applications using a range of different options. Machine manufacturers pursue different strategies in terms of voltage supply and battery storage requirements. In order to ensure that the installation space within the frame of the vehicle can always be optimally utilized, the eGFZ gearboxes with DIN ISO-compliant flange types enable a diverse range of drive solutions to be achieved. These can be executed in two-wheel drive as a U-shape or S-shape gearbox version and in four-wheel drive as a Z-shape version.

Practical know-how: a solid starting point

Company-wide knowledge of telehandlers, wheeled loaders and municipal machinery as well as tractors and reach stackers was pooled at the start of the development process to determine which of these drives could be driven electrically and centrally in the future – and with which load collectives. The new eGFZ gearboxes were developed and optimized based on this set of requirements. Bosch Rexroth now intends to work alongside its customers to determine the best solution for each specific application. The eGFZ 9100 and eGFZ 9200, which are currently being used in different pilot projects, will go into series production in 2022 as part of eLION. Rexroth’s platform for the electrification of mobile working machines covers the full range of electric motor-generators, inverters and accessories as well as tailored gearboxes, hydraulics and software.