C-B Gear & Machine Expands Capability with 5-Axis Milling

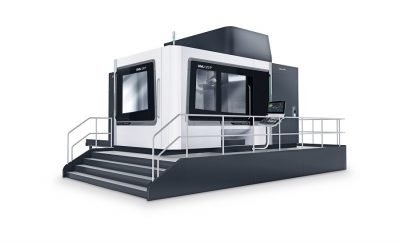

C-B Gear & Machine has expanded its precision milling capability with the addition of a new DMG MORI DMU 210P2 5-axis milling center.

The DMU 210P2 is one of a handful of five-axis milling machines in North America that can perform complex milling operations as well as mill gear teeth, making it state of the art machine technology. Reduction in set up and run times give C-B Gear a new capability for the high-speed production of any gear type on the market up to AGMA quality class 12 and higher. Cylindrical and right angle gearing up to 82” in diameter, soft or hard finished are possible.

Additionally, C-B Gear can now produce hard finished spiral bevel gears to either Gleason or Klingelnberg tooth forms. The DMU 210P2 adds to the company’s wide range of large precision gear manufacturing, which complements C-B Gear’s tooth grinding capability up to 4 meters in diameter. C-B Gear is one of the few gear manufacturing facilities in the country with this type of capability in this size range.

“We’re excited about the prospect of expanding into new markets with this type of capability” said C-B Gear General Manager, Frank Irey. “We’ve added all of the bells and whistles that help C-B Gear become even more competitive in the industry with on-board tooth inspection, tool offset compensation and automatic workpiece eccentric adjustments. Customers can expect higher quality and faster turn-around times than in the past”.

Since 1952, third-generation family-owned C-B Gear has been providing a wide variety of industries with quality products at a competitive price. “Expertise in precision mechanical component production, gear manufacturing and aftermarket gearbox repair has established C-B Gear as a highly valued supplier to our customers,” said Irey.