Ruland Expands Range of Quick Clamping Shaft Collars with Clamping Lever

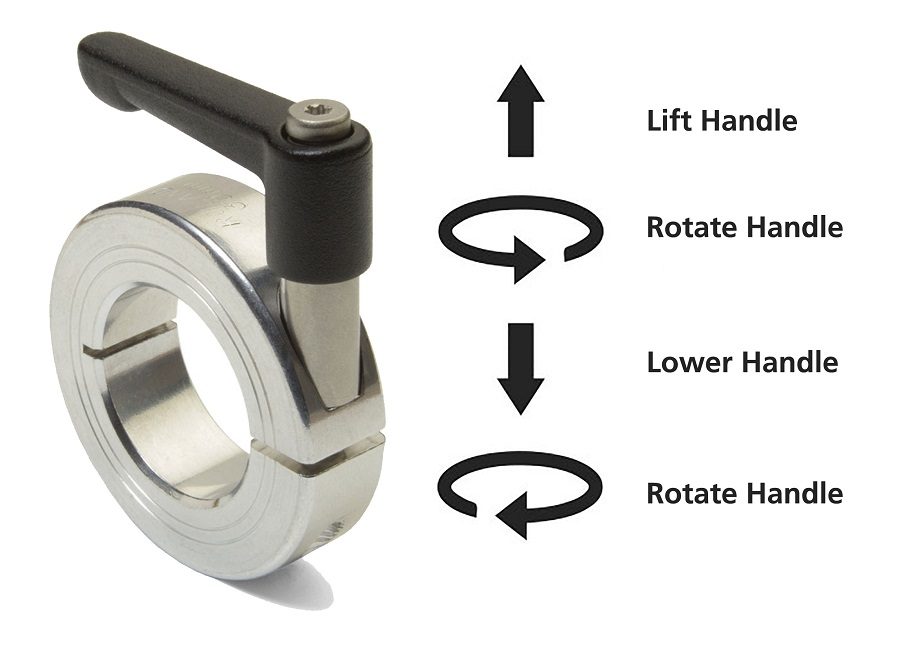

Ruland recently expanded their range of quick clamping shaft collars with clamping lever to include bore sizes up to 3 inches or 80 mm. These shaft collars allow the user to install, remove, or reposition the collar without the use of tools. The user simply turns the lever to loosen and tighten the collar on the shaft.

Quick clamping shaft collars with clamping lever combine a standard Ruland shaft collar with a custom designed lever designed to replace collar hardware. This creates a toolless shaft collar that can be rapidly adjusted, making them an ideal fit for packaging, printing, and other applications where frequent setup changes and adjustments are needed. The handle is steel with a textured zinc plated finish, allowing the user to easily grip the handle regardless of lubricants or other contaminants that may be on their hands. The stud is made from stainless steel to allow for increased corrosion resistance when combined with the zinc handle.

Ruland shaft collars have tightly controlled face to bore perpendicularity for proper alignment of mating components. Ruland identifies this work surface with one or two circular grooves on the face of the shaft collar to assist with installation. Perpendicularity is critical in applications where the shaft collar will be load bearing as it ensures even surface contact with the mated component.

Ruland’s expansion of quick clamping shaft collars includes bore sizes ranging from 1-3/4 inch to 3 inches and 42 mm to 80 mm. They are offered in high grade 2024 aluminum with an anodized finish for light corrosion resistance, 1215 lead-free steel for high strength and durability, and 303 and 316 stainless steels for increased corrosion resistance. Quick clamping shaft collars with clamping lever are available in one piece style and two-piece styles, giving the designer the flexibility to use the collar without shaft end access.

All Ruland quick clamping shaft collars are manufactured from select North American bar stock in Ruland’s factory in Marlborough, Massachusetts, under strict controls using proprietary processes. Levers are sourced from Otto Ganter GmbH and inventoried in Ruland’s factory for same day shipping with in-stock shaft collars. Full product information, 2D and 3D CAD files, installation videos, and more are available here: