Timken Offers Pintle Chain for Reliable Transfer and Conveyance Operation

The Timken Company offers a full selection of time-tested, engineered class pintle chain for ensuring reliable transfer and conveyance operation in a wide range of agricultural and material handling equipment.

For over 60 years, Timken Drives has provided extra-strength chain and extreme confidence to customers globally, including pintle chain built to convey bulk product in applications such as salt and sand spreaders, manure spreaders and live bottom trailers. Hay haulers and handlers, harvesters, baggers and sprayers can also benefit from pintle chain designed for dirty, demanding conditions that cause other chains to stiffen up or wear down quickly.

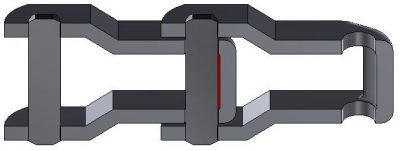

“In pintle chain you have a chain with an open back design which can operate in harsh environments without developing stiff joints due to material buildup in the bearing area (between the pin and barrel),” said Richard Neuhengen, product manager, Drives. In chain design, wear life (elongation) and articulation occur between the pin and bushing or barrel so a clean bearing area will improve wear life and prevent stiff joints. For decades, Drives has manufactured pintle chain that is specifically designed to operate in these harsh environments.

Pintle chain from Drives is rated for working loads from 560 to 8,000 pounds and offers a high working-load-to-weight ratio. Key design features include:

•Precision punched holes that increase the load-bearing surface area to maximize working strength.

•Low backing distance to the barrel that enhances the contact area between the pin and the barrel. This can greatly improve wear life when compared to chains with large backing distance.

•Compression formed Pintle chains that increase the working load and wear life over standard pintle chains by expanding the barrel contact area.

•Optimum press-fits to manage loading stresses and provide greater pin retention.

•Through-hardened, quad-staked pins to promote additional press-fit while resisting pin pullout due to side loading (proprietary heat treating of components produces the best combination of wear and toughness).

•Optimum heat treatment of the formed link that is required to operate in these corrosive environments. Higher working loads (tensile strength) can be achieved by increasing the hardness of the formed link. However, by increasing the hardness you make the formed link susceptible to breakage due to corrosion and shock loading (the formed link becomes less ductile). Engineered Class Chains by definition are chains designed for a specific application in a specific industry. Drives has accomplished this with our pintle chain offering.