ABB Reorganizes Ring-Geared Mill Drive Offerings

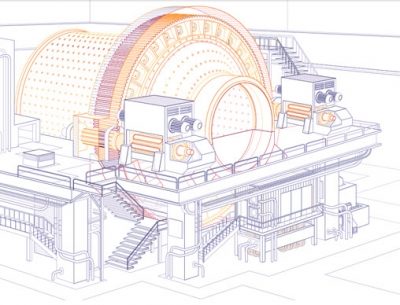

ABB has reorganized its ring-geared mill drive (RMD) portfolio to make it easier for its customers to identify and select the most suitable technology for their needs. Together with gearless mill drives (GMD), the RMDs power ore grinding mills, making them vital for mining operations and ore processing plants.

The enhanced product range clearly defines available solution options within ABB’s portfolio, which includes products and systems that fit specific technical requirements, process needs and budget constraints. Customers will be able to easily differentiate ABB’s RMD offerings through the following solutions:

RMDfsd (fixed speed drive): cost effective solution for projects with very constant ore grade throughout life cycle of the mine or for small ball mills that do not require variable speed.

RMDvsd (variable speed drive): variable speed solution, including soft-starting and optimum torque control for entire speed range. Suitable for any kind of grinding mill.

RMDplus: full variable speed solution, additionally including mill application features providing highest operational flexibility and optimizing maintenance actions.

SmartMill: combines all features from RMDplus with advanced process control technology, providing the ultimate control strategy. Ideal to increase productivity and energy efficiency.

“To better meet our customers’ needs, we have organized this solution family to make it easier to understand, choose and implement the RMD option that will deliver the best results for a specific process and plant.” says Marcelo Perrucci, global product manager within ABB’s process industries business unit. “ABB is committed to improving all aspects of the customer experience; this more transparent overview of our RMD portfolio reduces complexity in the product selection process while providing the solutions and services to help them to succeed in their operations.”