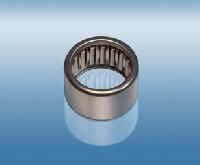

Hartford Introduces Drawn Cup Needle Bearings

Hartford Technologies, a global manufacturer of engineered bearing products for OEM and other high-volume applications, has introduced a broad line of Drawn Cup Needle Bearings. Drawn Cup Needle Roller Bearings consist of a stamped outer shell, cage and needle rollers. They are similar to standard roller bearings, except for a smaller diameter-to-length ratio, which gives them a substantial advantage in fitting tight envelopes. By controlling the clearance between the rollers, rollers are kept parallel to the axis of the shaft. The major advantage that needle bearings offer over bushings is that they operate with rolling motion, rather than sliding motion. As a result, friction is less, the torque required to rotate the shaft is lowered, less heat is generated and lubrication is simplified. The overall benefit to the user is that bearing wear is substantially reduced.

Hartford Drawn Cup Needle Bearings have a low cross section design which provides suitable load carrying capacity, increases power density and maximizes product life. They are manufactured in chrome steel, and low carbon steel in sizes as small as 3 mm ID by 6.5 mm OD. Applications are highly diverse, and range from two-stroke engines to towel dispensers. Other applications include automotive steering columns, outboard motors, power tools, appliances, office equipment and air compressors.

Hartford Drawn Cup Needle Bearings are typically open at both ends. Sealed Drawn Cup Needle Bearings are sealed at one end and are often used for shaft end mounting. The seal keeps the lubricant or non-pressurized oil from migrating, and prevents contamination of the raceway areas. Material options for Hartford bearings include chrome steel and low carbon steel; bearings can be supplied in lots as small as 500 pieces.