Product News

Product News

TSN

Provides Smart Manufacturing Communication Solutions

The Smart Factories of the future are highly productive, flexible and responsive because of their ability to leverage the power of data, which can offer a unique understanding of what is happening on the factory floor in real-time. As a result, companies can run automated processes to ensure smooth operations at all times, maximizing their efficiency. The backbones of such systems are their networks, which connect every part within a plant or enterprise to share key information. In order to support digital manufacturing functions, these infrastructures should be able to ensure the large volume of data generated is transmitted with high reliability and in a timely manner. The move towards gigabit bandwidth is further supporting these requirements.

TSN (Time-Sensitive Networking) can provide further support and help businesses create data-driven operations. Christian Bergdahl, product marketing manager at HMS Industrial Networks explains: “The most emphasized feature of this technology is its ability to turn standard industrial Ethernet into a real-time communications system with extremely low jitter and latency. Therefore, it provides the key network technology to support the latest data-driven solutions and smart manufacturing applications. These, in turn, are essential to help companies enhance productivity by creating responsive and flexible shop floors.”

He continues: “TSN will make industrial Ethernet deterministic by design and provide the basis of converged networks. In effect, the technology is being defined by the IEEE 802.1 specifications, which will set up a common, unified solution. As a result, any user will be able to benefit from a highly reliable and responsive network, whose nature supports interconnectedness, independently of vendor-specific solutions. This ultimately ensures openness and interoperability among automation devices and systems, simplifying the creation of well-linked plants and enterprises.”

Furthermore, TSN has the ability to bring different parts of an enterprise, such as the operational technology (OT) and information technology (IT) sectors closer together. “The technology was originally developed for transferring audio and video streams in commercial applications. Only later, this solution has been looked at to support industrial automation systems. As a result, TSN applications in a given sector will be influenced by the developments in another segment, shaping and converging the future of the technology and industries themselves,” adds the HMS Industrial Networks specialist. This unique feature will also play a crucial role in enhancing the acceptance of TSN.

Automation system builders and end users are highly perceptive and well aware of the potential of TSN, particularly its ability to provide a unified way towards interoperability. Therefore, many companies are actively looking forward to adopting this technology. Furthermore, it is a well-accepted concept that TSN will certainly become a must-have in the short- to mid-term. In fact, the extensive roll out of innovative industrial Ethernet solutions is a matter of when, not if — and businesses are ready to act now.

Currently, the creation of TSN-based solutions is experiencing a growth phase and it is certainly a thrilling time for the technology specialists. Bergdahl comments: “Fieldbuses and conventional Ethernet have been established for many years. Now that the innovation of TSN is here, engineers are up for a new challenge as they develop new products with ground-breaking capabilities. It is truly inspiring to see how committed and motivated these teams are.”

A challenge in driving the TSN revolution may be shaping successful collaborations between automation vendors, according to Bergdahl. “As the key element of TSN is interoperability, specialists need to be willing to collaborate closely to develop suitable systems and migration solutions. Within such a framework, existing networks of key automation players, such as the CLPA, are on the right path and have a competitive advantage”.

“Being part of the CLPA has always been extremely beneficial. With TSN, we are witnessing a number of unique advantages. In addition to being able to rely on a community of leading automation experts, we can be the first to develop TSN-compatible devices by utilizing the CC-Link IE TSN specifications. This is the first network technology incorporating the innovative TSN standards that was released to the market. By offering the earliest solutions with TSN, we can enhance our role and acceptance in the automation sector, particularly in Asia, where the CLPA’s technologies are de facto standards. The first product appearing from HMS in mid-2021 will be the Anybus CompactCom for CC-Link IE TSN, which will allow device makers to easily implement this new promising technology.”

Bodine Electric

Provides Explosion-Proof AC and BLDC Gearmotors and Motors

Bodine Electric Company recently introduced forty new Ex-Proof AC and BLDC gearmotors and (4) new motors, that are UL listed for use in environments where ignitable concentrations of flammable gases, vapors or liquids are likely to exist under normal operating conditions. These new CI/D1 geared motors combine Bodine’s high-performance type 34R6 (inverter-duty AC) or type 34B6 (brushless DC) motors with an integral parallel shaft type FX gearhead. Typical applications include chemical injection pumps for the oil and gas industry, automated equipment for use in aircraft hangars, petroleum refineries, dry cleaning plants, fuel servicing areas, chemical processing (cannabis distillation), or industrial coating and mixing facilities.

These new gearmotors and motors meet National Electrical Code (NEC) Class I, Division 1 requirements, and are rated for use in areas where groups C and D flammable liquids are commonly found. The gearmotors meet UL temperature codes T3C and T4A. Both the type 34R6-FX (AC) and the 34B6-FX (BLDC) gearmotors and 34-frame motors are rated IP-66, meaning they can safely withstand water jets from any direction.

The initial product launch includes 40 standard gearmotor models with gear ratios from 5:1 to 300:1 with speeds from 5.3 to 560 rpm. Rated torque ranges from 46 lb-in (5 Nm) to 350 lb-in (40 Nm). Bodine Ex-Proof gearmotors and motors are available with low-voltage (12 or 24 VDC) brushless DC windings, and 230VAC or 460VAC inverter-duty, 3-phase windings. The CI/D1 AC and BLDC motors are available with two NEMA C face mounting options.

The model 0931 base mount kit fits both the new type 34R6BXPP-FX (AC) and 34B6BXBL-FX (BLDC) gearmotors, as well as on the corresponding AC and BLDC, CI/D1 motors. Bodine type 34R/34B AC and BLDC, CI/D1 motors meet NEMA-56C mounting specifications when the optional base mount kit 0931 is installed.

Bodine’s new Class I Division 1 gearmotors and the 0931 base mount kit are available through Bodine’s extensive distributor network or from the Bodine website. Custom options are available to qualified OEMs. Typical OEM modifications include custom windings, application-specific mounting options or special drive shafts

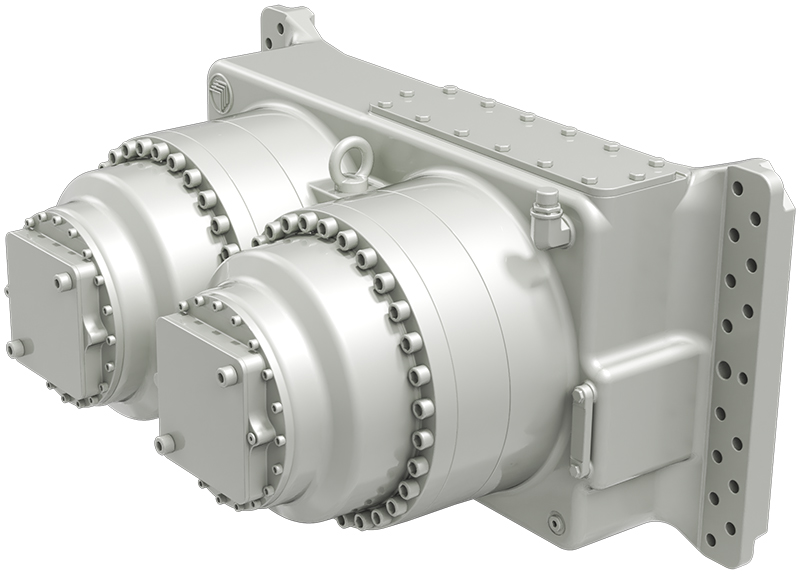

Bosch Rexroth

OfferS Fast, Power-Dense Hydraulic Motor

The smallest of the Hägglunds hydraulic motors from Bosch Rexroth has been transformed. The Hägglunds Atom takes over from the existing Hägglunds CAb — supplying not only more revolutions per minute, but also far more power than motors of similar size. The result is a tiny, power-dense package ideal for mobile, marine and recycling applications.

Revamped and renamed, the Hägglunds Atom is a powerhouse in miniature, with a maximum torque of up to 13.6 kNm and a specific torque of 40 Nm/bar. Because it supplies full torque at speeds up to 400 rpm, it has a maximum power of 394 kW that outstrips other motors in its class.

“Never has so much power been packed into a motor this small,” says Wolfram Ulrich, vice president sales Hägglunds products and solutions at Bosch Rexroth. “The Hägglunds Atom, with its substantially higher torque and power, is a motor that deserves its name — unthinkably small and light, but with the power to change everything for customers.”

Among those who will benefit from the Hägglunds Atom are customers in mobile, marine and recycling applications. The compact and lightweight motor fits on a winch on land or at sea, and can easily handle shock loads at peak pressure of up to 420 bar. That opens the door to smaller shredders and other machines in tough and unpredictable applications.

“The Hägglunds Atom is rugged and robust, like our larger Hägglunds motors,” says Ulrich. “That makes it just as dependable as it is versatile.”

In fact, the Hägglunds Atom is the first of many new names that will appear in the Hägglunds family. In a departure from technical designations, all motors will soon be renamed after natural and scientific phenomena. That reflects not only the extensive development that has occurred since their introduction, but also illustrates its key characteristics today.

“Striking and memorable names will help guide customers to the Hägglunds motor that meets their needs,” says Ulrich. “In a way, this is a strong return to form. The original Hägglunds motor was the Hägglunds Viking — a motor and a name that have never been out of popular use.”

www.boschrexroth-us.com/hagglundsatom

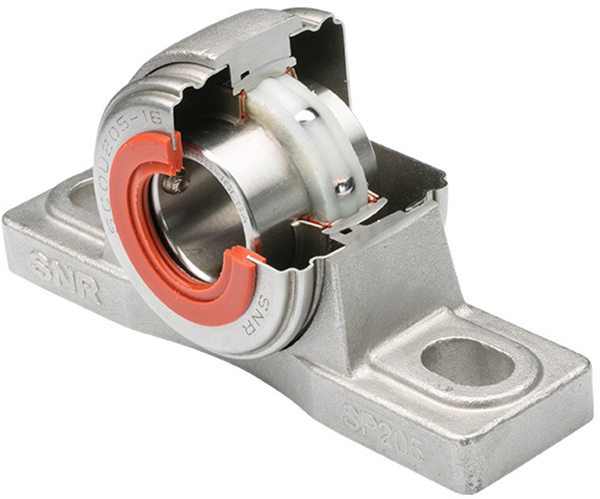

NTN

Revamps Sentinel Series

NTN Bearing Corporation of America has announced that its Sentinel Series product line has been revamped to encompass a more expansive offering. NTN’s Sentinel Series is a premium line of corrosion-resistant products ranging from deep groove ball bearings, bearing inserts, and mounted units developed for the harsh conditions of the food & beverage industry. Products are available in numerous combinations of housings — including the recently added three-bolt flange –, protective covers, sealing options, and food-grade standard or solid-lubrication grease. Whether an application requires the ultimate wash-down protection of stainless steel units, caustic resilience of thermoplastic housings or the value performance of zinc, Sentinel Series provides a family of food & beverage market solutions to improve overall equipment effectiveness, increase production, and provide value.

“This is an exciting announcement for NTN,” said James Misch, director of marketing and technical services, NTN. “We have been working on the renovation of our Sentinel Series line for quite a while and are thrilled to see the hard work culminating in this moment. We will continue to update and expand the Sentinel Series line and its’ supporting literature to ensure that we are offering our customers the widest breadth of food & beverage industry solutions while supplying them with the information they need to safeguard against downtime.”

As part of the relaunch, a new Sentinel Series catalog that gives a broad overview of the updated line has been created. Additionally, 256 Sentinel Series SKUs now live in Bearing Finder, NTN’s digital support platform designed to aid distributors, design engineers, and end users in finding the perfect bearing or related product to use in any application. In total, Bearing Finder now houses 39,945 SKUs.

Bearing Finder is hosted on a proprietary platform that offers a customizable part search tool, interactive and downloadable CAD illustrations, comprehensive part interchanges, and exhaustive data sets. It’s part of NTN’s industry-leading suite of training and cataloging entities.

Bonfiglioli

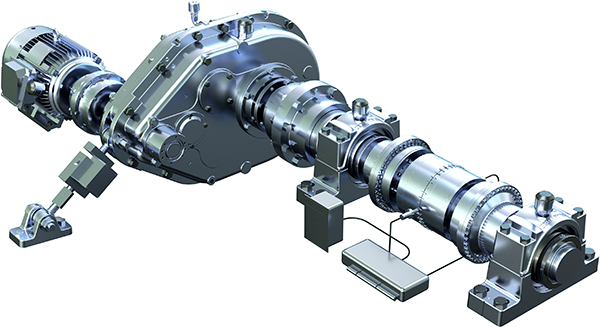

Introduces New Planetary Drive Series

Bonfiglioli presents the new R3 planetary gearbox series, designed specifically for recycling machines such as shredders and others. The planetary drives are available in four sizes with a torque range from 129,000 up to 370,000 Nm and gear ratios from 56 to 117. The R3 series is compact and powerful. Their planetary gear train makes them the ideal choice for all severe duty applications where shock loads and impacts are the rule rather than the exception. Adverse conditions, which often prevail in the recycling process, are easily absorbed by the gearbox. The robust R3 planetary gear drives impress with an extremely favorable torque/size ratio and run perfectly even at low speeds. Fast speed changes are no problem for the compact yet extremely powerful R3 gearboxes.

The product configuration is highly flexible, due to several options for mounting, gear layout, output shaft and motor interface. According to the torque need and customer machine layout, R3 series can be equipped with 1, 2 or 4 hydraulic motor adapters. Electric motor adapter is also available upon request.

Bonfiglioli planetary drives are the ideal choice for harsh operating conditions. This is especially true for applications in which load peaks occur frequently. Their planetary drives are able to exploit their fundamental strengths in comparison to other types of drives: Their constructive design ensures load distribution, protects the bearings and extends the service life.

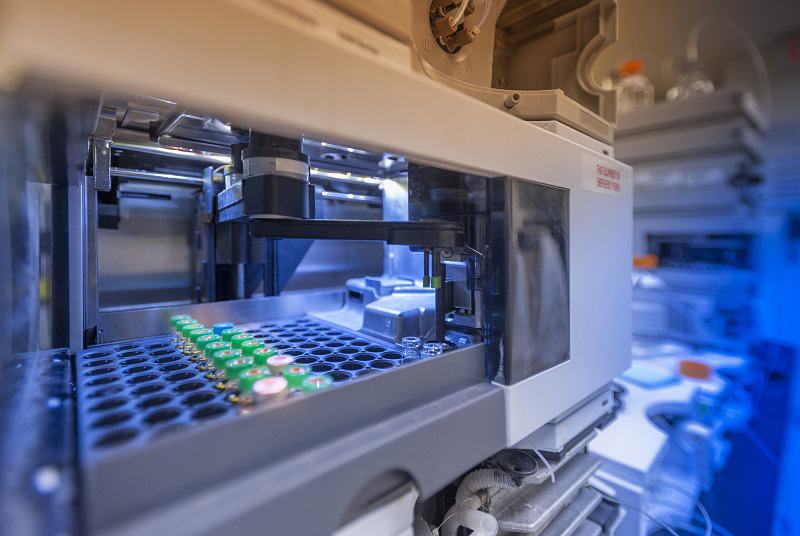

ETEL’S Motion Controller

Offers Real-Time Processing for Complex Manufacturing Applications

ETEL’s new UltimET Advanced is a powerful and versatile multi-axis motion controller now available to bring fast real-time processing and a higher level of flexibility to a variety of complex manufacturing applications. This standalone controller from ETEL, a Heidenhain company, is perfect for high-level machine processes in the electronics and automation industries, and of special note in front- and back-end semiconductor manufacturing operations.

As motion control architecture has increased in complexity including the larger amounts of data processing required, so has this expansion of the ETEL motion controller line. With its embedded real-time operating system, quad-core processor, and proprietary algorithms, the UltimET Advanced’s architecture has been expanded to meet this challenge.

For example, many front- and back-end semiconductor applications require precise control of movements with multiple axes and powerful controllers to make on-the-fly calculations, correct motion trajectories, and must compensate for environmental factors that affect overall system accuracy. Typically, these types of tasks are handled by the host PC which executes the code before sending data back to the controller. This creates limitations in speed and code size. The UltimET Advanced is a standalone “box format” motion controller with an embedded real-time operating system that allows it to both compile and execute a customer’s code, which reduces latency and frees up the PC’s resources. This is accomplished through its quad-core processor which dedicates one of its cores to customer processes and computations.

The UltimET Advanced allows for incredibly fast, multi-axis motions with the high bandwidth that ETEL AccurET line of controllers typically provide along with TransnET’s 1ns communication synchronization, delivering best-in-class motion trajectory performance. Along with computation speed, the architecture allows for easy integration of analog and digital external sensor data into the control loop which provides real-time motion system performance monitoring and critical data logging. All of this ensures the machine’s reliability over its lifetime.

Other features include a free development environment (so that the customer’s code is not IP dependent) and extended interfacing capabilities such as PCIe and TCP/IP. To make the most out of these features, ETEL offers a consulting service to ensure that a customer’s machine can reach its highest potential in performance that the UltimET Advanced was designed to offer.

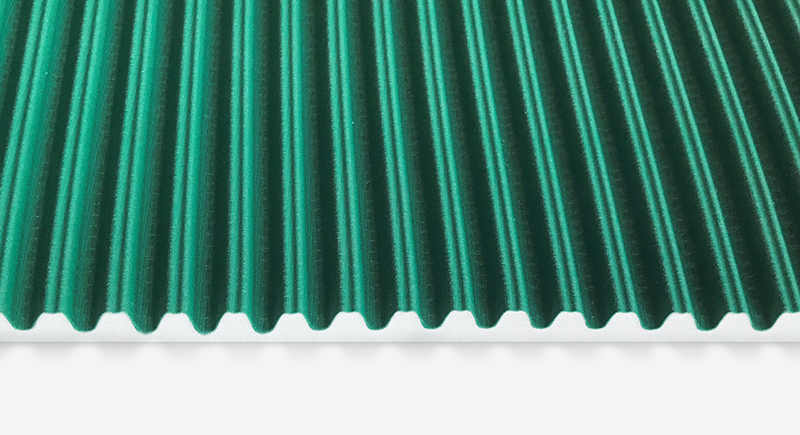

Gates

Expands TPU Belt Series

Gates has announced the introduction of two new thermoplastic polyurethane (TPU) belts, the Gates Parabolic Pitch (GPP) in 8mm and 14mm profiles. The new GPP belts are stronger, more durable, quieter, safer to operate and require less maintenance than other alternatives, including alternative rubber belts, roller chains and steel cables.

“At Gates, we’re continually in search of market opportunities where our materials science expertise and drive to innovate can create added value for our customers. The new GPP belts are the latest examples of our efforts,” said Scott Manley, general manager, Gates TPU. “In addition to expanding our TPU product range, GPP is another example of our commitment to replace legacy technologies with engineered belt solutions that are more efficient, lighter, cleaner, safer and quieter to operate than traditional roller chains, and last up to five times longer than steel cables.”

Engineered to outperform the competition, the high-strength, reinforced steel (RSL) GPP 14-RSL has the highest break strength of any 14 mm pitch TPU belt on the market, and the standard product versions are compatible with Timken’s RPP sprockets, making them suitable drop-in replacements across a wide range of applications. All Gates GPP belts are equipped with nylon fabric on the tooth sides for high abrasion resistance and quieter operation, and the optional low-temperature construction provides an operating range from minus 30 degrees up to 50 degrees Celsius. GPP belts complement Gates’ existing TPU belt line-up and provide reliable, precision operation across a wide range of industrial applications, including intralogistics, material handling, vertical lift, door opening and industrial automation.

GPP belts are currently available in the North America and EMEA regions.

SDP/SI

Simplifies Motion System Design with Integrated Motors

Robotics and industrial automation industries are facing design and production challenges with the urgent need for premium quality parts and services. Stock Drive Products/Sterling Instrument (SDP/SI) is launching a series of Integrated Motors to simplify motion system design.

Replacing multiple components with a compact all-in-one motor and electronics package, Integrated Motors simplify motion system design while providing many advantages.

“Doing speed, position and torque closed-loop control with separate brushless motor and driver/controller technologies can be challenging,” said Jacques Lemire, business unit director, Motors & Motion Control. “Our integrated motor controllers provide easier set-up, smaller and cleaner motion control solutions. By keeping the wiring from the motor to the driver short, integrated motor controllers are the perfect solution for reducing the communication time for the signals from the drivers to the motors.”

SDP/SI products are available with a wide range of standard features for easy integration intended for industrial automation applications. The Integrated Motor Controllers include state-of-the-art brushless servo motors with 4096 lines encoder and CANOpen network protocols in an intelligent plug-and-play package. The high-performance 60 mm NR5-LD60M series incorporates motor, encoder, and drive with smooth and quiet sinusoidal commutation with Field Oriented Control (Vector Control) into a compact unit. The NEMA 23 NH5-DM series is an economical turn-key solution to speed and torque analog motion control. With the elimination of multiple components, connectors, cabling, and labor a significant cost savings is realized.

To cover any system requirements SDP/SI offers DC Motors, AGV Gear Motors and a wide range of AGV accessories including optical flow sensor, magnetic track following sensor, and controller network communication options.

Dana

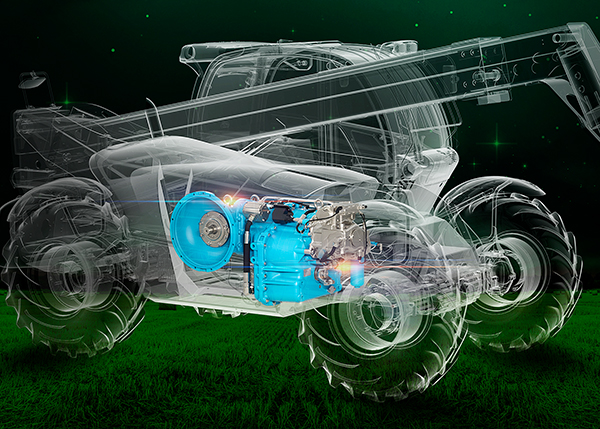

Introduces Spicer HVT1 Transmission

Dana Incorporated has announced the Spicer HVT1, an advanced powersplit transmission that enables the superior performance and sustainability of agriculture telehandlers.

The Spicer HVT1 supports power inputs from 110 to 155 horsepower (80 to 115 kW) and offers fuel savings of up to 30 percent when compared with agriculture telehandlers that use conventional transmissions.

“Buyers of agriculture telehandlers are looking to maximize the value of their investments through equipment that provides efficiency, versatility, sustainability, and power to get the work done,” said Aziz Aghili, executive vice president and president of Heavy Vehicle for Dana Incorporated. “The Spicer HVT1 has been engineered to deliver the superior performance and exceptional long-term value that equipment owners demand.”

Currently undergoing field tests with several global original-equipment manufacturers, the Spicer HVT1 leverages more than a decade of Dana expertise in developing hydromechanical variable transmissions for the off-highway market. Dana already produces market-ready HVTs for construction, agriculture, material handling, and forestry applications.

It supplies significant advantages across the board over existing competitive conventional transmissions, helping next-generation telehandlers achieve new levels of productivity, performance, control, refinement, fuel efficiency, ease of use, and operator comfort.

Performance in Every Duty Cycle

The unique design of the Spicer HVT1 provides numerous benefits that address the expanded performance expectations of agriculture telehandlers operating in the farmyard, field, and road.

Its distinctive combination of hydrostatic and mechanical drives in an integrated 90-degree gearbox offers exceptionally precise low-speed maneuvering control and smooth, progressive response for loading and handling cycles. It also delivers superior climbing and high-speed towing capabilities up to 31 mph (50 km/h).

It allows agriculture equipment buyers to increase the utilization of telehandlers by supplying maximum torque for a wide range of rigorous work demands, such as digging and loading.

To maximize machine productivity in widely varying duty cycles, the Spicer HVT1 uses an advanced electronic control system to continually adjust the mix of hydrostatic and mechanical power, allowing the engine to maintain a consistent speed in its most efficient operating range. It is compliant with ISO standards that govern the safety of control systems for earth-moving machinery, tractors, and other agriculture and forestry machinery.

KISSsoft

Offers Crossed helical gear calculations

The gear calculation in KISSsoft covers all common gear types such as cylindrical, bevel, hypoid, worm, beveloid, crown and crossed helical gears.

In the KISSsoft Release 2021, new graphics for the crossed helical gear calculation are available: The evaluation graphic for specific sliding is calculated and displayed based on the geometry of a spur replacement cylindrical gear. A visual evaluation of the tooth meshing in 2D is now also possible for axis crossing angles not equal to 90°. For this purpose, parallel sections to the center axis plane of the worm are calculated and shown. This 2D geometry is visualized using the “Tooth meshing in slices” function. The option “Determine form diameter dFf and dFa from tooth form” is also selectable.

With the help of the fine sizing method in KISSsoft, you can also find the best variants for crossed helical gear stages with preset, definable boundary conditions. If you input the nominal ratio, normal module, pressure angle, helix angle, center distance and profile shift coefficient, the system calculates and displays all the possible suggestions.

All the variants the system finds are then output in a list, classified by the most varied criteria (accuracy of ratio, contact ratio, safety factors, weight, axial forces etc.). You can either expand or reduce the scope of the list, if you want to display more or fewer individual results for a specific solution.

Regal

Enhances its Powertrain Capabilities

Regal Beloit Corporation is continuing to enhance its industrial powertrain capabilities. Regal is now even better positioned to maximize uptime and reduce energy consumption in customers’ powertrain applications, whether for new builds or existing installations.

The Regal electromechanical powertrain offering encompasses a broad range of Regal-produced components (e.g., motors, speed reducers, gearing, couplings, bearings, belt drives and more) that can be integrated to create complete end-to-end solutions, customized to meet specific application requirements, and optimized to maximize energy efficiency and productivity. In addition to helping customers design, assemble and commission their powertrains, Regal can monitor a solution’s ongoing performance through its cloud-based Perceptiv internet of things (IoT) platform. Data collected and analyzed via Perceptiv can support a wide range of diagnostic and prognostic activities, enabling customers to sustain high performance from their assets.

“At Regal, we create a better tomorrow and endless potential for our customers by energy-efficiently converting power into motion,” said Louis Pinkham, Regal’s chief executive officer. “We optimize our engineered mechanical power transmission components and motors to work better together, more efficiently and effectively. The ongoing asset monitoring we offer across the powertrain with Perceptiv intelligence helps to maximize uptime and prevent costly outages, while simplifying the maintenance, repair and operations experience for our customers.”

Pinkham continued, “Earlier this year, Regal announced a transformational merger with Rexnord’s Process & Motion Control business, which is on track to close in the fourth quarter. The merger is expected to further enhance our capabilities across the industrial powertrain, especially in higher-torque applications, where Rexnord is strong, while deepening our presence in attractive high-growth end markets such as renewable energy, aerospace and e-commerce, and in a broader set of geographies.”

Currently, Regal’s electromechanical powertrains are used within industries such as bulk and unit material handling, metals, pulp and paper, mining, and other critical industrial applications.