Integrated Hybrid Servo Motors vs. Standard Integrated Servo Motors

Integrated Hybrid Servo Motors vs. Standard Integrated Servo Motors: How Do They Stack Up?

Different motor types favor different application areas. No single style has advantages in all application spaces. Direct drive applications favor hybrid servos while high-speed, geared down applications tend to favor the conventional servo motors. Misapplication of a conventional servo into a direct drive application may result in just one-third of the expected efficiency and provide only 40% of the continuous power at a typical application speed. This leads to 160% to 450% more heat being dissipated by the conventional integrated servo motor, as compared to a similarly sized NEMA 23-frame (4 inches long) integrated hybrid servo motor.

Integrated servo motors fall into a couple of main camps, i.e. — traditional low-pole-count AC brushless, and hybrid servo, which use high-pole-count AC brushless motors. The latter may also be used open-loop as step motors. The integrated hybrid servo motors — as used in this comparison — are operated as true servo motors using vector drives. These comparisons do not hold for step-loss, prevention mode step motor drives — even though the same style of motor may be in use. This closed-loop vs. open-loop performance difference is also true of low-pole-count motors in that a given motor generally performs significantly better when using a full servo control than when that same motor is operated open loop using a variable speed drive.

Fundamental Motor Differences

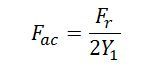

Hybrid servo motors are based on high-pole-count (typically 100-pole) motors — typically called “step motors” in open-loop operation. Traditional servo motors normally use lower-pole-count (typically 4-16-pole) motors. Given the other motor factors being the same, the torque constant (Nm/A) for a motor increases with the number of poles, and the speed goes down by the same ratio. The torque constant (if losses are accounted separately) equals the voltage constant when expressed as volts/radian/sec. In this example comparison, “A” brand integrated servo motor lists the voltage constant as 6.6v/1,000 rpm, which corresponds to .06 v/radian/sec, thus equaling .06 Nm/A, and a winding resistance of 1.1 ohm. The QCI integrated hybrid servo has a measured voltage constant of .227 v/radian/sec, and a winding resistance of .66 ohms. This means that this conventional servo requires more than 3.5 times as much current to produce the same torque at the shaft as does the hybrid servo. Power loss is calculated in the copper windings by Ploss equals I2R. This corresponds to more than 20 times the power dissipated, just to hold the same torque when the motors are stopped. Thus a high-torque constant is very beneficial at low to medium speeds; however, the high torque constant also causes a higher motor back-EMF for a given speed, which reduces the voltage available to the drive current into the motor at higher speeds. This condition limits the top speed of the motor. These differences make the hybrid servo motor very useful for many direct drive applications, but limits their use in very high-speed applications, where the lower-pole-count motor wins out.

Comparing Torque Curves

Donald P. Labriola II, president and founder of QuickSilver Controls, Inc., specializes in servo controllers and motors, with a special focus on cost-effective motion control. He has been granted eleven U.S. patents as well as numerous international patents. His background includes over 40 years of motion control, including 20 years in medical instrument design. Labriola enjoys gardening, camping and Ham radio — and motion control!

Donald P. Labriola II, president and founder of QuickSilver Controls, Inc., specializes in servo controllers and motors, with a special focus on cost-effective motion control. He has been granted eleven U.S. patents as well as numerous international patents. His background includes over 40 years of motion control, including 20 years in medical instrument design. Labriola enjoys gardening, camping and Ham radio — and motion control!

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.