Designing systems to avoid EMI/EMC issues takes some serious effort at times. And sometimes “improvements” only make it worse.

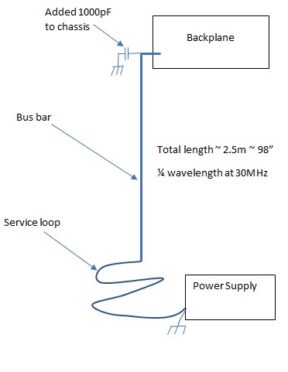

One system I got called in on had the power supplies mounted on a rack with a small service loop connected to a heavy laminated bus bar which brought the power up a few feet to where the drive circuitry was located. The safety ground connection to the chassis and DC power ground were connected together near the power supplies.

The noise in the system was almost one volt at 30 MHz between the chassis ground and the power ground at the top of the bus bar. On the next pass, the engineer involved increased the thickness of the copper ground plane in the bus bar to about .5 centimeters (0.2 inches) x 2.5 cm (1 inch) wide — much more than needed for the currents involved. The new pass was installed and the voltage actually increased about 10%. This was the opposite of what was expected.

I was brought in to take a look. A quick calculation put the bus bar plus the service loop at around 2.5 meters (98 inches). This put it almost exactly a quarter-wavelength at 30 MHz. For those who don’t remember their transmission line theory, a quarter-wave transmission line transforms a low impedance at one end to a very high impedance at the other end. A small, high-impedance signal at the high-mpedance end travels down to the low impedance (short to ground), which causes the reflection to be inverted such that the sum of the forward and reflected wave at the short cancels out. The signal then returns to the high-impedance end of the transmission line. If the frequency is such that the transmission line provide a 90 degree phase shift in each direction, the signal comes back with 90 degrees for the travel down, 180 degrees due to the short at the bottom, and another 90 degrees for the travel back, which puts it in phase with the original signal. This resonance can be quite strong; this is how a one-quarter wavelength antenna works.

Further investigation revealed that there was a 10 MHz-square-wave signal source of only a couple of milliamps was in the upper bay, with the 3rd harmonic exciting the resonance.

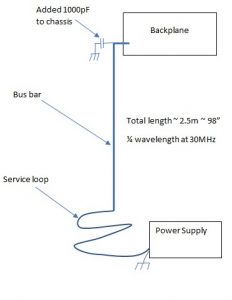

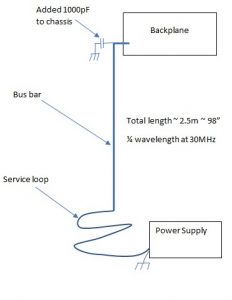

The solution was simply to add a small capacitor (1,000 pF if memory serves) between the chassis and the ground at the top of the bus bar. This dropped the impedance at the top to about 5 ohm (at 30 MHz), and the noise down from 1.2 v down to less than a millivolt (what we could measure). The effect is not only from the drop in impedance at the top, but from the fact that the top was no longer the “high-impedance end,” so that the signal reflecting from the top was no longer in phase with the signal coming up from the bottom — destroying the 360 degree round trip.

Note that that there are also other harmonic frequencies for which the signal down and back will end up in phase and cause a similar problem. These happen at frequencies where the round trip is N*360 degrees. As these are higher harmonics, the same capacitor technique is also effective.

A good understanding of the issues can speed troubleshooting. And preferably avoid it all together!

Donald Labriola P.E. is president of QuickSilver Controls (www.QuickSilverConrols.com.)

One system I got called in on had the power supplies mounted on a rack with a small service loop connected to a heavy laminated bus bar which brought the power up a few feet to where the drive circuitry was located. The safety ground connection to the chassis and DC power ground were connected together near the power supplies.

The noise in the system was almost one volt at 30 MHz between the chassis ground and the power ground at the top of the bus bar. On the next pass, the engineer involved increased the thickness of the copper ground plane in the bus bar to about .5 centimeters (0.2 inches) x 2.5 cm (1 inch) wide — much more than needed for the currents involved. The new pass was installed and the voltage actually increased about 10%. This was the opposite of what was expected.

I was brought in to take a look. A quick calculation put the bus bar plus the service loop at around 2.5 meters (98 inches). This put it almost exactly a quarter-wavelength at 30 MHz. For those who don’t remember their transmission line theory, a quarter-wave transmission line transforms a low impedance at one end to a very high impedance at the other end. A small, high-impedance signal at the high-mpedance end travels down to the low impedance (short to ground), which causes the reflection to be inverted such that the sum of the forward and reflected wave at the short cancels out. The signal then returns to the high-impedance end of the transmission line. If the frequency is such that the transmission line provide a 90 degree phase shift in each direction, the signal comes back with 90 degrees for the travel down, 180 degrees due to the short at the bottom, and another 90 degrees for the travel back, which puts it in phase with the original signal. This resonance can be quite strong; this is how a one-quarter wavelength antenna works.

Further investigation revealed that there was a 10 MHz-square-wave signal source of only a couple of milliamps was in the upper bay, with the 3rd harmonic exciting the resonance.

The solution was simply to add a small capacitor (1,000 pF if memory serves) between the chassis and the ground at the top of the bus bar. This dropped the impedance at the top to about 5 ohm (at 30 MHz), and the noise down from 1.2 v down to less than a millivolt (what we could measure). The effect is not only from the drop in impedance at the top, but from the fact that the top was no longer the “high-impedance end,” so that the signal reflecting from the top was no longer in phase with the signal coming up from the bottom — destroying the 360 degree round trip.

Note that that there are also other harmonic frequencies for which the signal down and back will end up in phase and cause a similar problem. These happen at frequencies where the round trip is N*360 degrees. As these are higher harmonics, the same capacitor technique is also effective.

A good understanding of the issues can speed troubleshooting. And preferably avoid it all together!

Donald Labriola P.E. is president of QuickSilver Controls (www.QuickSilverConrols.com.)