Nord’s IE5+ Permanent Magnet Synchronous Motor Technology Receives New Design and Frame Sizes

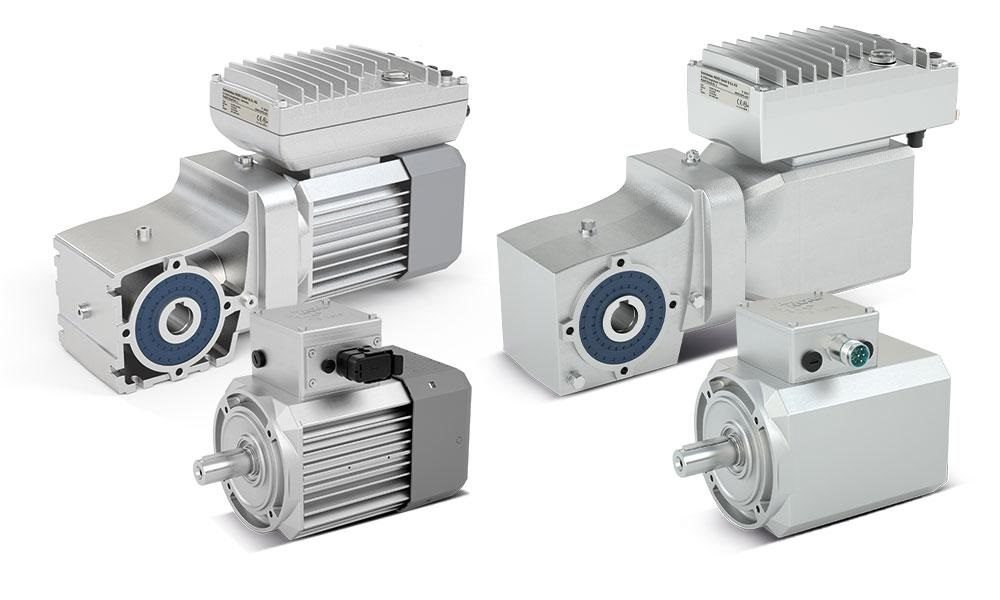

With the introduction of their first IE5+ permanent magnet synchronous motor in 2021, Nord Drivesystems delivered a new standard of energy efficiency, variant reduction, and reduced operating costs. This Size 71 TENV smooth surface design has paved the way for additions to the IE5+ product family including ventilated designs and larger frame sizes to expand performance and versatility even further. These motors are UL/CSA certified and can be utilized across a wide range of industries and applications.

The new motors include a larger Size 90 TENV, as well as a new TEFC ventilated design. The Size 90 TENV smooth surface IE5+ motors extend the power range of these hygienic motors up to 3 hp and they are ideal for washdown areas such as food and beverage applications, pharmaceuticals, and other applications where high corrosion resistance is required. The smooth, fan-less design increases productivity due to more efficient cleaning processes and provides cost savings as cleaning requires fewer chemicals, less water, and less energy. Nord’s TENV IE5+ motors are available with IP69K protection or can be treated with Nord’s nsd tupH Sealed Surface Conversion System to withstand the toughest operating environments.

In addition to the smooth surface design, Nord has developed a ventilated TEFC IE5+ motor for use in intralogistics, packaging, post and parcel, and manufacturing. The ventilated design enables cool operation with a high overload capacity and constant torque over the full speed range of 0.5 – 5 hp. These motors come in two frame sizes, 71 and 90, and feature a motor integrated encoder as well as an optional integrated mechanical brake.

Like the original Size 71 TENV design, the latest IE5+ motors are fully compatible with Nord’s modular system of gear units and variable frequency drives. Flexible mounting options include integral mounting to Nord gear units, IEC B5 flanges, IEC B14 flanges, and NEMA C-Face adapters. The compact footprint of both designs provides installation flexibility and the ability to adapt these motors to a wide range of applications, especially those where space is limited. Small size combined with minimal noise emissions, high overload capacity, and high energy efficiency make IE5+ motors a great investment for reducing system variants and ultimately lowering Total Cost of Ownership (TCO).

IE5+ motors are part of the new NORD product portfolio that is raising the standards of drive system technology. This innovative portfolio also includes the Duodrive integrated gear units and the Nordac On/On+ decentralized VFDs that are engineered to work in conjunction with IE5+ motor technology.

Together these units focus on maximum energy efficiency and are engineered to save operational costs over time.