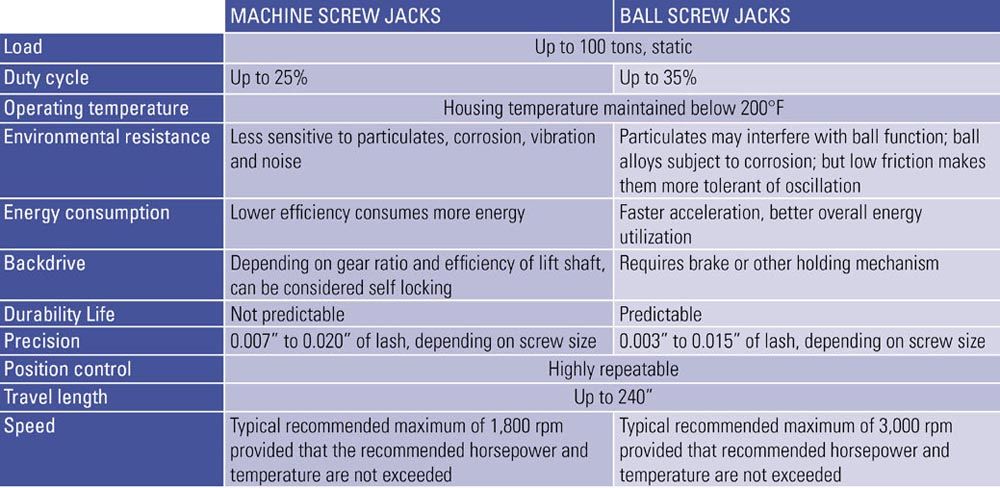

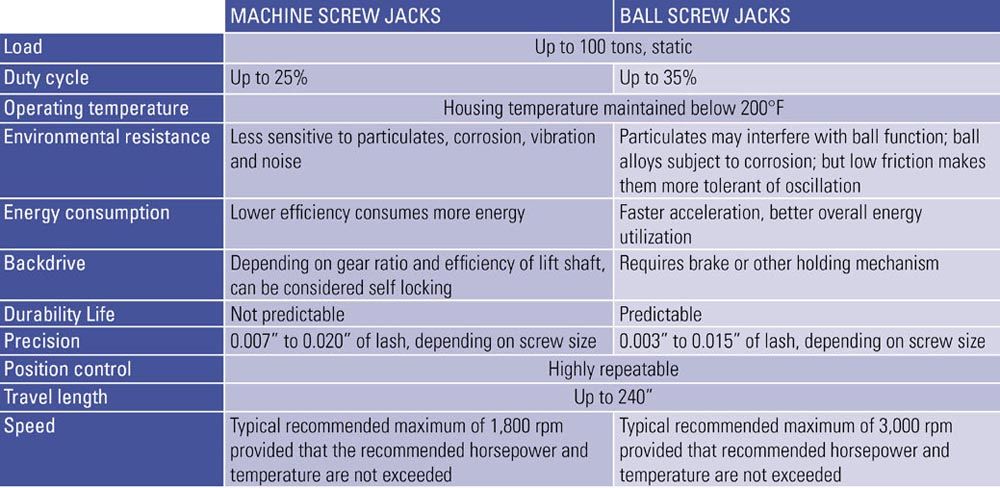

Efficient energy usage also gives ball screw jacks an advantage in reducing costs. Because of their efficiency, ball screw jacks require less horsepower to operate and thus consume less energy. This feature enables designers to specify a smaller motor to meet sustainability objectives. However, this choice does depend on other application variables, including the duty cycle, environment, and speed.

A simple horsepower calculation can determine the proper size of screw jack to use in each application. In addition, measuring the housing temperature can ensure the jack’s usage is not exceeded. Suppose the

temperature exceeds the screw jack’s limitations. In that case, the designer might still benefit from a more cost-effective machine screw jack but would need to use a larger jack, reduce the motor input speed, or use a right-angle reducer. Otherwise, they can use a ball screw jack to take advantage of their higher efficiencies.

The high-friction operation of the machine screw within a jack requires about twice as much input torque, so a larger motor would also be required. In applications in which either multiple machine or ball screw jacks are configured in a system, a single motor could drive all jacks, further improving energy efficiency. A scissor lift, for example, might deploy jacks driving its left and right sides with a connecting shaft in between. One motor can drive both jacks (Figure 3).

Figure 3. The two screw jacks on this scissor lift can work with a single motor. If the duty cycle was less than 25 percent, they could operate with a machine screw jack, which might counter the higher energy consumption.

Tolerance for backdrive

Axial pressure on the lift shaft or travel nut can push it backward, especially if a brake or other holding mechanism in a vertical orientation fails or the system loses power. In such cases, the relative inefficiency and high friction potential of machine screws give them an advantage over ball screws. Depending on the gear ratio and efficiency of the lift shaft, machine screw jacks can be considered self-locking.

The high efficiency of ball screws used in vertical configurations can cause them to slide backward easily if power goes down. For that reason, ball screw jacks must be outfitted with a brake or other holding mechanism, adding cost and complexity.

Presence of particulates, corrosive chemicals, vibration, and noise

While ball screws have an advantage in high-duty-cycle applications, machine screws have advantages where particulates, toxic chemicals and vibration are present, or excess noise can be an issue.

Machine screws are less sensitive to contamination, making them better for areas in mills or woodworking where particulates might fill the air. Machine screw jacks can be supplied with stainless steel to prevent corrosion in high-moisture environments. Ball screw jacks can utilize various plating techniques to achieve similar benefits.

Machine screw jacks are less sensitive to vibration and quieter because no balls are recirculating. This makes them preferable in noise-sensitive environments such as residential or healthcare settings.

Need to predict life cycle

The engaged frictional thread of the machine screw jack makes it difficult to predict its life cycle. Ball screw life cycle, however, can be calculated based on measurable inefficiencies that contribute to fatigue of the ball bearings under a dynamic load. Known as the L10 standard, this calculation estimates the number of revolutions or hours at a given constant speed that 90 percent of a screw system’s group of bearings will complete or exceed before failure. It is impossible to predict the life of machine screws, so if end users need to predict the life of their screw jacks, the ball type is the only option.

Need for precision

Both machine screw jacks and ball screw jacks are highly repeatable. Depending on size, they will have an associated lash between 0.003 and 0.020 in. This can be reduced using a clearance ball nut or a split drive nut for the machine screw jacks.

Need for position control

Both machine screw jacks and ball screw jacks can be motor driven and provide position control options. However, the higher the precision required and the higher the duty cycle, the more the application would gain from using a ball screw jack.

For example, a tilt station platform supporting a team working on a large airplane wing might use multiple ball screw jacks synchronized in communication via a CAN bus network. However, if the platform needed adjustment only two or three times per week, a machine screw jack would be adequate. In that latter case, even a machine screw jack equipped with a single general-purpose motor—using shafting to mechanically link each jack—might be sufficient.

Logical choices

In many applications involving loads of up to 100 tons, screw jacks can provide a desirable alternative to hydraulic cylinders. Still, it is important to specify the correct type of screw jack. For static loads with duty cycles below 25 percent, a machine screw jack will usually be the most cost-effective. For dynamic loads with higher-duty cycles, a ball screw jack is necessary.

However, within those broad parameters, many other factors could affect the decision. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Ball screw jacks, on the other hand, have more predictable life cycles.

Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. No matter which screw jack you choose, their increased control, tremendous power, easier installation, and environmental friendliness will instill confidence in your motion system design.

motion.com/pte

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.