Bosch Rexroth Releases Electromechanical Kit for Pressing and Joining Applications

Bosch Rexroth’s new, innovative Smart Press Kit is designed to meet future industrial requirements and provides a complete mechatronics package that is immediately ready for use across an extremely wide range of standardized pressing and joining applications. The modular kit, consisting of mechanical components, electrical components and software, simplifies product selection and configuration as well as commissioning. The Smart Press Kit can be connected via open interfaces and conveniently monitored on a tablet during operations. This maximizes transparency, reduces downtime and increases productivity.

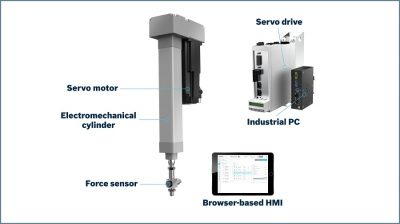

This easy, fast and attractively priced solution is specially designed for pressing and joining processes in the low force range of two to 30 kN. The modular system consists of perfectly synchronized hardware and software components: an electromechanical cylinder and power sensor, servomotor, drive controller, industrial PC and browser-based HMI software based on HTML 5.

There are numerous potential areas of application for the new Smart Press Kit – it is ideal for applications where simplicity, fast commissioning and price are important criteria. These include press-fitting bearings in housings, crimping cables and hoses and inserting (for example, integration of magnets in lamination stacks). Furthermore, the Smart Press Kit is cost-effective at forming processes, such as bending, embossing and deep drawing in the plastics industry. The system is also suitable for measurement and test procedures as well as test stands across an extremely wide range of sectors. The Smart Press Kit is a versatile solution and can be used as a standalone or integrated into superior systems via field bus. As such, Bosch Rexroth is setting new cross-industry standards for easy pressing and joining applications.

Fast product selection and commissioning

Simply start by choosing the right Smart Press Kit size using Rexroth’s LinSelect software tool. Then the final configuration process is carried out in the online configurator. CAD files can then be downloaded and the desired configuration can be ordered via the Rexroth e-shop. All components are delivered as one complete package.

The true highlights of the Smart Press Kit are the intuitive commissioning and process configuration, meaning programming knowledge is not required. Thanks to the integrated motion control, the preinstalled operating software, the auto-parameterization of the servo drive, the low number of interfaces and a wizard make fast commissioning possible. This saves up to 95% engineering time and can significantly reduce time to market.

Intuitive software – no programming knowledge required

Even during operation, the software is intuitive and can be used without programming knowledge. Due to the modern Web HMI, process configuration takes place via drag and drop. An easy graphical creation of evaluation and analysis elements is practically self-explanatory. During operations, the Smart Press Kit can then be conveniently monitored via a tablet. The visualization of status information and process results, including a live display of the force-displacement curve with subsequent analysis, storage and data export options, ensure maximum transparency. All current system parameters are always available at a glance: whether a status report, quality statistics or error messages. They appear as plain text in the software and make error handling simple. Other predictive maintenance functions and maintenance support are currently in the works. Thanks to all these functions, the Smart Press Kit reduces downtime and maximizes productivity.