Rexroth A2FM 70 Series Bent-Axis Motor Now Available in Three Pressure Levels

Rexroth recently announced its new A2FM 70 series bent-axis hydraulic motors, motors designed to provide higher power in a smaller installation space. The motors are up to 26 percent shorter and have a high power density. At the same time, Rexroth has added two extra pressure levels to the new series, which now covers the pressure range up to 500 bar.

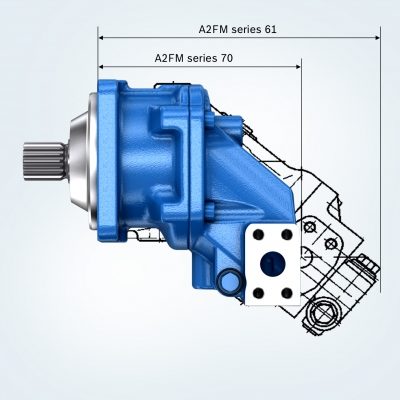

The smaller dimensions in the new Rexroth axial piston motors with a 40 degrees bent-axis design have been achieved by optimizing the design of the rotary unit and using an integrated flushing and boost-pressure valve. Depending on the size selected, the motors are up to 26 percent shorter than series 61. This improvement also reduces the weight of the motors by up to 38 percent– for instance, the weight of the size 107 (pressure range of 300/350 bar) drops from about 32 kg to around just 20 kg.

The 70 series, which has been developed to complement Rexroth's medium pressure pumps, has additional pressure levels to expand the range of application for the A2FM hydraulic motors. In addition to the maximum pressure of 450 bar provided by the previous series, variants with maximum pressures of 350 and 500 bar are now also available.

Thanks to three different pressure levels, the A2FM is suited for cost-sensitive applications with lower pressure demands as well as heavy duty applications with higher pressure demands. Three sizes, with displacements of 80, 90 and 107 cm³ respectively, are suited to a range of tasks in mobile working machines. Like the A2FM 61 series, the new fixed motors feature a high starting efficiency and are designed for speeds of up to 5,000 rpm. They can be used in both open and closed circuits.

The fixed motors can drive drums in concrete mixers, winches in mobile cranes or vibration drives in road rollers. They are also suitable for use in drilling equipment and rolling mills. Rexroth also combines the new motors with axial piston pumps to create ready-to-install, compact hydrostatic travel drives for use in snow groomers and combine harvesters, for example.