SKF’s Sealing Solutions Eliminates Need to Rework Problem Shafts

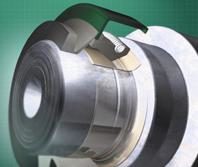

SKF’s "Speedi-Sleeve" offers a sealing solution when machine shaft surfaces have been damaged or worn in operation.

Simple replacement of the original radial seals over a worn surface cannot provide effective sealing performance. Wear sleeves eliminate the typical need to replace or rework shafts whose surfaces have been compromised by abrasion due to environmental contaminants, high pressures, speeds, or inadequate lubrication.

According to the company’s press release, Speedi-Sleeves$B%g(B quickly mount by pressing them over the damaged shaft surface. Power tools or heating is not required. Shafts can be up-and-running within minutes. Each Speedi-Sleeve fits a specific shaft range and their extremely thin walls (0.28mm/.011") allow users to retain the original seal size.

Speedi-Sleeves are made from stainless steel for corrosion resistance and exhibit a surface roughness between 0.25 mm to 0.51 mm (10-20 min.).They often can deliver a higher quality counterface for the seal lip than encountered with the original shaft. Selected sleeve sizes also are available as Speedi-Sleeve Gold. This version features a special coating, which reduces the rate of abrasive wear in demanding, contaminated operating conditions.

Shafts with diameters up to 203.20mm (8") can be equipped with standard Speedi-Sleeves and, for larger shafts (diameters up to 1143.00mm or 45"), the heavy wall type "LDSLV" chrome-plated, carbon steel wear sleeves can be specified.

All Speedi-Sleeves feature a removable installation flange for easy mounting using a tool supplied with each sleeve. The flange can be retained or removed, if necessary, for clearance purposes (a pre-cut tear groove is provided).

Product News