12 Current Trends in Motion Control

12 Current Trends in Motion Control

Smart Factory solutions hint at machine design potential in 2018

Matthew Jaster, Senior Editor

The future of motion control is connectivity. Conversations continue to revolve around the concept of the smart factory — a plant where manufacturing blends data and production seamlessly and integration is the be-all, end-all to long-term success. While we’re not there yet, the concepts, technologies and potential of the smart factory is certainly taking shape in manufacturing today.

For every challenge facing machine builders, the answer will most likely come in the complete optimization and digitalization of products and services. Actuators, servo drives, encoders, servomotors and software provide solutions for a wide range of industrial applications today. These components will be pivotal in driving the technology needed to run the smart factory of the future. Here’s how the motion control industry is capitalizing on the latest products and technologies:

1. Creating More Flexible, Modular Machines

Daniel Repp, industry manager, automation at Lenze, believes it’s no longer only about connecting drives and transmitting data to subordinate systems, but rather providing software to support the OEM in the development of flexible, modular machines.

This can be as simple as making frequently-used machine functions available as standardized technology modules or adding pre-configured and tested software modules via the application template and adjusting the parameter settings.

“Automation specialists should work the way they are used to — with a basic architecture. The functions are enclosed in the individual modules. The modules are autonomous and can easily be exchanged and tested completely independently. The software toolbox provides standard software modules for positioning, cam profiling, multi-conveyor coordination, and other synchronized motion control tasks, including modules for feeding, unwinding, sealing, cross-sealing and pick and place robotics,” Repp said.

Up to 80 percent of machine software engineering requirements are covered by the modules available from Lenze’s FAST platform.

“This leaves more time for the machine builder to focus on the development of a machine’s special performance features. It also allows for a savings on engineering costs while, at the same time, speeding up the machine design process,” Repp added.

2. More Servo Module Options

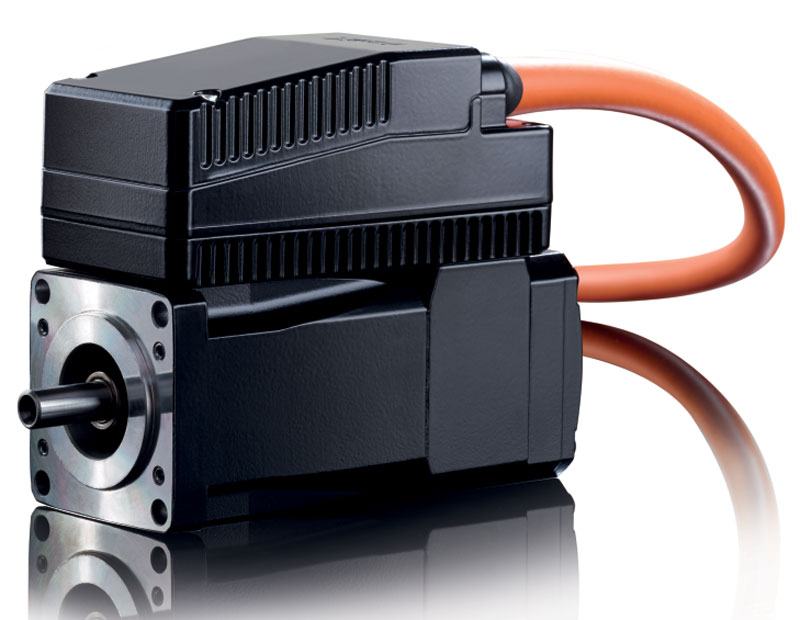

Because the cost of power electronics and motor components are decreasing each year (relative to economic forces), AMK is making an effort to replace more motion on a machine with servo modules. Things that once had to be pneumatic due to costs are now in the range of servo control which gives the OEM the ability to create machines without timers — now they know absolutely where the mechanics of the machine are at all times.

“Because of the power of the digital signal processor (DSP) we are using, we are able now to create motion systems that do not need a centralized controller,” said Tom Jensen, general manager at AMK Automation. “This makes the machines we are on actual “machine modules” and makes things like robotic cells, conveyor integration possible in a small cabinet — or likely cabinet free,” Jensen said.

3. Ease of Installation

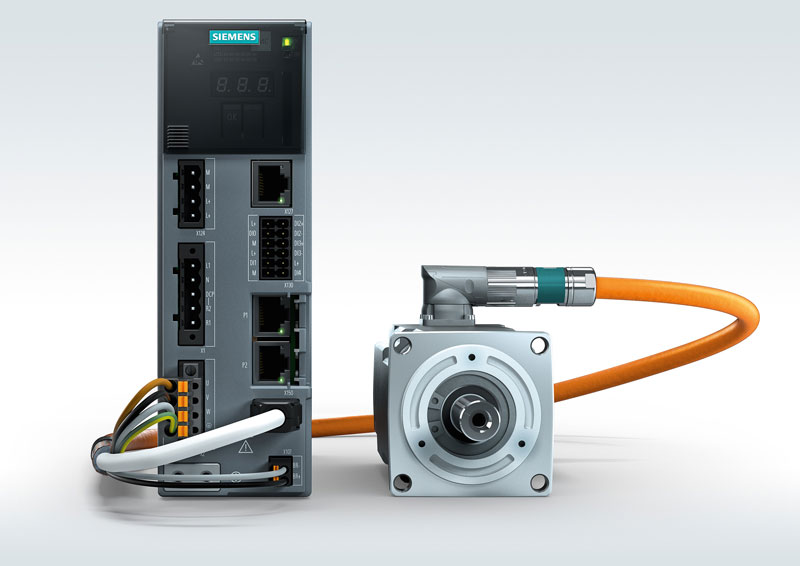

On the installation front, Craig Nelson, senior product manager at Siemens Industry, Inc., said it is now very common to only use a single cable between servomotor and drive on servo systems which reduces the installation time and cable trays — the result is a simple install that increases productivity and efficiency.

“This is made possible by the fact that encoder signals are now sent via serial communication, which, once shielded properly, can be run in the same hybrid cable as the motor power leads and brake leads,” Nelson said.

4. Innovations in Remote Diagnostics

Jensen said that remote diagnostics are a focus of every automation company because of the times we live in, but they need to provide an action path for the machine owner to be effective. Therefore, AMK is working on a combined Remote/HMI diagnostic to harmonize the pathway to keeping machines running.

“As an example, automobiles today have enough dashboard (HMI) information that the driver knows what is going on (tire pressure, fuel, oil, etc). What this connectivity provides is the next step in the process–where to find service, gas, oil. What this combination can do for plant machinery is to effect a course of action when an alarm arises (call the right maintenance personnel, but also plants can reduce speeds and cycle machinery based on plant environmental conditions, power input conditions and other external variables keeping the operator and machine efficient even when conditions aren’t,” Jensen said.

Repp said that Lenze is moving far beyond simple remote maintenance by enabling its customers to be IIoT-ready — a key element for future machine development.

“We find that when IIoT systems communicate with each other, their value is multiplied. This makes interoperability essential and increases the benefits exponentially. As technology segments get closer and grow together through digitalization, these cross-functional innovations become more likely to occur,” Repp said.

5. Trusting Engineering Experience

One thing AMK is focused on in the United States is the elimination of templates, according to Jensen. For years the automation industry has focused on templates to hide the complexity of machine programming, with the goal of making training and adoption simpler.

“This strategy only works if the team developing the template can make a template that every engineer understands. The strategy therefore has worked well in niche markets (robotics), but has made general automation much more complex (that is why you don’t (but could) use a robotic controller on a conveyor cell,” Jensen said.

AMK has instead created training and tools based on the fact that the U.S. automation engineers are the best and can handle IEC 1131 programming environments as they are.

“Our bet is that a little more up front training will allow engineers to create great machines well beyond the initial training with support only needed for new forward-looking machine concepts,” Jensen said.

6. Staying Connected to the Cloud

Nelson at Siemens Industry, Inc. said that the increased connectivity of servo systems to Ethernet-based communications for control and integration into cloud-based analytics represents a future-proof trend with instant payback as little or no additional costs are typically occurred.

“Built-in Industrial Ethernet interfaces are common for most all servo drives today with some offering connectivity to multiple Industrial Ethernet protocols such as Profinet or EtherNet/IP.” Nelson said.

7. Single Software Solutions

Jensen said the question of software is not as simple as pointing at the PC based editor most engineers see, because software exists at every level (in every processor) of the motion system — from the firmware in the motor module through the PC environment.

“AMK has a single software solution based on IEC61131, and our tools in the environment are incredibly effective because of the harmony from the single motion control block at the IEC level to the firmware in the drive. With a handful of function blocks and our integrated tools, we can truly make any machine — quickly and in the OEMs methodology,” Jensen added.

Repp said that Lenze has integrated all the safety functionality into their existing programming software tools.

“We offer one programing tool, the Lenze PLC Designer, for all programming demands. Whether it’s motion or logic programming, or safety implementation — it’s all covered by one product,” Repp said. “Safety functions are also implemented in our FAST automation software modules. This allows the machine builder to follow the modular programming standard not only for the machine application program, but also for the safety part.”

8. Factoring in Safety

Machine safety is pivotal in the building process, according to Jensen. Without risk analysis completed for each machine design, the machine will have a hard time being insured making the final sale difficult.

“Technology providers then have to be able to show how to use their systems to eliminate risk conditions in the best way,” Jensen said.

As humans are required to interact more frequently with machines — and robots, in particular — machine safety becomes an even higher priority.

“We have taken this into consideration and integrated the safety functions directly into the different parts of our portfolio — servo inverter, servo motors, controls and engineering tools,” Repp said. “Because we understand that these trends are continuously evolving, we offer a safety solution — controller-based and drive-based that provides optimal support to the customer and makes his machine ready for future safety requirements.”

9. Adapting to Changes on the Plant Floor

Safety functions for servo systems and the machinery they control are undergoing a radical change on the plant floor. Here, technology is rapidly changing as robots, automated systems and autonomous guided vehicles (AGVs) become the norm.

Nelson believes the time has come to adapt to these changes faster and more efficiently.

“Gone are the cabinets of safety relays and contactors with the proven and flexible adaption to safety integrated drive functions with safety signals now coming from a failsafe protocol over Industrial Ethernet. New safety functions for motion control such as Safe Limited Position, Safe CAM and Safe Torque are game changers for increased safety and productivity today,” Nelson said.

10. Consumer Integration

It’s no secret that when it comes to automation and motion control, the industrial community lags behind the consumer market by a wide margin.

“In the near future, the automation industry can expect the continued influx of technologies from the consumer market into their portfolios,” said Jensen. “Concepts found in mobile devices and automobiles — Wi-Fi, multiple cameras, etc. — will become inexpensive and developed enough that automation engineers will begin to use them. “

Repp said that consumers love individualized products. Technologies such as web-based car configurators, individualized beverage containers or sport shoes have already proven to be successful in the marketplace.

“The flexibility of a production system for the manufacture of individually customized products is therefore comparable to the Holy Grail of production technology,” Repp said. “The advancement of digital technology — like cheap and high-CPU performance, or small and cheap memory — means the long-lasting technological dreams of flexible, autonomous and cost-efficient production systems, are now very close to becoming reality. This is not only true for consumer goods, but also for industrial production.”

In short, consumer automation may hold the key for future products and technologies coming to the industrial market with one awfully large caveat — technical solutions take time. An Iphone, Fitbit or pair of running shoes won’t come with the security concerns, safety requirements, environmental challenges or power needs found in a pump manufacturing plant or a wind turbine. This is where research and development will be key to reimagining motion control technologies.

“We need to take advantage of apprentice and mentoring programs to integrate and test consumer products with our portfolio to see what is possible,” Jensen added. “Ideas like controllerless automation are innovations that have come from this process.”

11. A Digital First Approach

Repp is confident that the trend in motion control for the next five years is the digitalization of industrial processes. “To improve the quality of new developments, and reduce development time and costs, many activities will be outsourced into digital processes — a trend that is already occurring. With continued developments of the IIoT and Industry 4.0, machines are becoming more connected. Machine builders will benefit from the optimization of each singular machine, since they can easily be adapted for the whole machine system. Digital twins of machines will help to reduce development time and associated cost. Virtual reality environments will improve the tests and completion of new machines.”

12. Learn, Adapt and Innovate

Each new concept on motion control starts with conversations with current customers. How these products and technologies are put to use — and their effectiveness — will determine the course of action for future developments. The feedback received from a servo drive today will influence how these components will be adapted to new industrial applications down the road.

Motion control systems — including controllers, servo drives, rotary and linear servo motors, linear actuators and software — will continue to evolve as long as machine builders, engineers and product specialists continue to strive to make these systems faster and more efficient.

The concept of the smart factory may still lie behind the curtain, but it’s slowly and methodically being pulled back to reveal a promising future for manufacturing production.

For more information:

AMK Automation

Phone: (847) 565-2652

http://us.amk.systems/

Lenze Americas

Phone: (248) 706-6061

www.lenze.com

Siemens Industry, Inc.

Phone: (800) 879-8079

www.siemens.com/us/en/home.html

Back to Basics:

Motion Control or Robotics?

Both concepts overlap in several areas, but there are significant differences between motion control and robotics. This sidebar aims to clear up some of the confusion with some assistance from National Instruments, New York University and Omron Adept Technologies.

National Instruments defines motion control software and hardware as the development of products and technologies that solve a diverse set of application challenges, faster and at a lower cost. These components can be applied to robotics, but fall under the motion control umbrella:

Motion Control

Application software — You can use application software to command target positions and motion control profiles.

Motion controller — The motion controller acts as the brain of the system by taking the desired target positions and motion profiles and creating the trajectories for the motors to follow by outputting a ±10 V signal for servo motors, or step and direction pulses for stepper motors.

Amplifier or drive — Amplifiers (also called drives) take the commands from the controller and generate the current required to drive or turn the motor.

Motor — Motors turn electrical energy into mechanical energy and produce the torque required to move to the desired target position.

Mechanical elements — Motors are designed to provide torque to some mechanics. These include linear slides, robotic arms, and special actuators.

Feedback device or position sensor — A position feedback device is not required for some motion control applications (such as controlling stepper motors) but is vital for servo motors. The feedback device, usually a quadrature encoder, senses the motor position and reports the result to the controller, thereby closing the loop to the motion controller.

Looking at Motors in Motion Control Applications

The most common motors in the industrial and embedded space are stepper, brushed, and brushless DC motors, but there are other motor options. Each motor requires individual input signals to spin the motor and transform electrical energy into mechanical energy.

In the broadest sense, motion control helps you use the motor that best meets your application requirements without dealing with all the low-level signaling needed to spin a motor. In addition, motion control provides high-level functions so you can efficiently implement custom applications based on building blocks to create solutions for common tasks like precise positioning, synchronization of multiple axes, and movement with defined velocity, acceleration, and deceleration.

Robotics

According to NYU, the first programmable robot was designed by George Devol, who coined the term Universal Automation. He later shortened this to Unimation, which became the name of the first robot company back in 1962.

Industrial robots gained recognition and rapid growth during the 1980s. During this time period many institutions began introducing programs and courses in robotics. Robotics courses are spread across mechanical engineering, electrical engineering, and computer science departments and they continue to grow today as the focus turns toward mechatronics and big data.

The design and operation of robotic systems includes dynamic system modeling and analysis, feedback control, sensors and signal conditioning, actuators (muscles) and power electronics, hardware/computer interfacing and more.

What Solution Fits Your Application?

A company like Omron Adept Technologies offers both motion control systems as well as existing robotic technologies. Most motion control components can be used in addition to an existing robot or it can be designed as a stand-alone system. Omron has installed more than 30,000 robotic and motion control systems in a variety of industrial applications.

While a customer may be wondering if a motion control or robotic solution would be more appropriate for their automation needs, the truth is that motion control is really a sub-system of robotics. For example, many components in motion control — actuators, motors, etc. — makeup the nucleus of a Selective Compliance Assembly Arm (SCARA) robot. However, you can create an automation system without using robotics with the right engineering experience.

This typically comes down to the engineering support and technical background within an organization. Productivity and efficiency can improve if you have the expertise to combine motion control hardware and software for an automation cell. But, an easier, hassle-free approach may be to incorporate a few robotic units on your plant floor. They are already assembled, easy to setup and offer an immediate turnkey solution.

The answer to motion control or robotics lies in how much time and money you’re willing to invest for the requirements of your application.