Here's a recap of some recent product and industry news articles on smart bearings, motors and drives where IIoT and digital solutions are pushing component technology into the future:

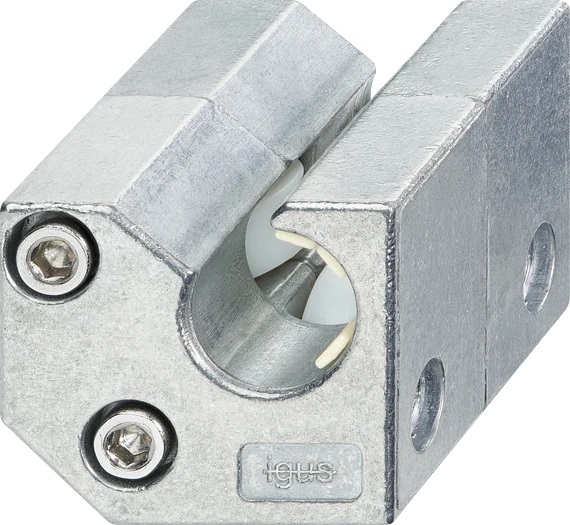

Igus Offers Digital Solutions for Hybrid Roller Bearings

Motion plastics expert igus has recently introduced a service life calculator tool for their WJRM line of hybrid rolling bearings. This lesser-known product line combines drylin linear bearing technology with ball bearings to reduce friction, making them ideal for manual adjustments.

The WJRM bearings are applicable across multiple industries – wherever linear motion is needed. Medical, 3D printing, furniture, and more can all take advantage of what WRJM hybrid roller bearings offer. Of course, as with most products from igus, the bearings are self-lubricating, eliminating the need for maintenance and reducing operational volume compared to metallic bearings.

The new digital tool for the WJRM line offers a few different services. It can calculate the service life of the system, as well as provide pricing and drive force. This is the first-time service life for these hybrid roller bearings will be calculable for customers, joining the ever-growing list of products from igus that offer service life calculators. Knowing exactly how long a product will last is essential in planning maintenance schedules and avoiding unplanned downtime for the system.

“The new tool makes finding the perfect system easier than ever and having the drive force and service life clearly stated at the end, is really helpful in making sure our parts are right for your system,” says Jennifer Harding, product specialist at igus.

ABB Opens B&R Innovation and Training Campus

ABB opened its new global innovation and training campus at the headquarters of B&R in Eggelsberg, Austria, its global center for machine and factory automation. The new campus will create up to 1,000 additional high-tech jobs and includes world-class research and development laboratories, as well as global training facilities for up to 4,000 people per year in collaboration with universities. ABB invested EUR 100 million in the expansion of the B&R headquarters.

Campus innovations around artificial intelligence and machine and factory automation will play an essential role in unlocking the potential of future industrial production – in sectors such as electronics, e-mobility, food and beverage, recycling, logistics, or agriculture. They will increase productivity and flexibility, helping customers become more sustainable and produce closer to their end markets.

“Innovation has been in ABB’s DNA for more than 130 years and our division, B&R, is a true innovation hot spot for the transformation towards more automated manufacturing. The official opening of this campus is a proud moment for our ABB as we create highly skilled jobs while shaping the machines and factories of the future together with our customers,” said ABB CEO Björn Rosengren.

The new campus expands the total area of B&R's headquarters to more than 100,000 m², making B&R one of the largest sites for integrated production, research, and training in central Europe, with currently around 2,400 employees. The expansion will also free up space which will serve as additional production capacity to meet increasing demand for B&R products.

Sami Atiya, president of ABB’s Robotics and Discrete Automation business area, added, “This is a decade of transformation towards robotics and automation as our customers respond to global labor and supply shortages, accelerating consumer demand for personalized products and the need to operate more sustainably. ABB’s new campus will serve as a customer collaboration center where we work with customers around the globe, helping them to respond to these trends and supporting B&R in becoming the partner of choice for the world’s most ambitious industrial automation projects.”

With the acquisition of B&R in 2017, ABB is the only company offering industrial automation customers the entire range of integrated hardware and software solutions around control, actuation, robotics, sensing as well as analytics and electrification.

The ABB innovation and training campus will serve as an open innovation hub, where B&R will closely collaborate with international customers, companies, and start-ups from across the region, as well as research and educational institutions to co-develop automation solutions and train the talents needed for the factories of the future.

Telit Opens Corporate Headquarters in California

Telit, a global enabler of the Internet of Things (IoT), recently announced a new global corporate headquarters in Southern California. Following the CEO’s move to the U.S., the new headquarters is in the City of Irvine—Orange County’s technology hub—and will support Telit’s strategy to grow its connected devices and solutions business worldwide. The Irvine office will also serve key projects and customers in the region, widening its U.S. presence that currently includes offices in Ill., FL., and N.C.

“These are exciting times for Telit,” said Paolo Dal Pino, CEO, Telit. “Choosing a global headquarters in California is a move consistent with the objective of strengthening our market position as a leading western player in the IoT connected devices and solutions arena. Particularly now—with a 100 percent Western shareholder structure—it’s a move that poises Telit for major growth and expansion in 2022 and beyond.”

Today, Telit’s headquarters, research and development centers, and sales and operations offices continue to expand globally, with 28 locations on six of the seven continents which include R&D centers in the U.S., Italy, Korea and India. As a driver enabling Industry 4.0. and digital transformation, Telit provides enterprises with best-in-class device management and connectivity solutions that are essential to technologies powering smart cities, transportation, manufacturing, automotive, retail, healthcare and beyond. Telit’s IoT experts—renowned for pioneering a successful end-to-end system approach—ensure Telit modules, connectivity and platforms all work seamlessly together to scale IoT deployments today and in the future. In addition to implementing thousands of successful IoT solutions worldwide, Telit continues to invest in its technology roadmap to push the industry forward for years to come.

The Irvine location is now open and operating.

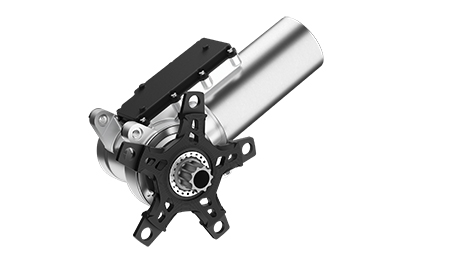

Maxon and Thömus Collaborate on E-Bike

With the new Lightrider E Ultimate, Swiss bicycle manufacturer Thömus is launching the world's first full-suspension cross-country electric mountain bike weighing less than 15 kilograms. This record-breaking weight is made possible by the small and efficient maxon BIKEDRIVE AIR drive in the extremely lightweight Thömus ultra-high modulus carbon frame.

The partnership between Thömus and drive specialist maxon that began in the winter of 2021 is delivering results not only in World Cup racing. Behind the scenes, a lot of work has been done on a new, ultra-lightweight electric mountain bike in recent months, which, together with the maxon BIKEDRIVE AIR drive, heralds a new era for electric mountain bikes. Weighing less than 15 kilograms in total and with a slim, rigid frame, the Lightrider E Ultimate is a real racing bike that can be maneuvered easily and agilely over any terrain.

For Thomas Binggeli, CEO and owner of Thömus, the new development is a milestone: “We developed the Lightrider E Ultimate in close cooperation with maxon and our World Cup team. The feedback we have had from training on the ride and the low weight has been amazing. The new e-bike is not designed with just professional athletes in mind, however. Every cyclist can enjoy this unique riding experience.”

The barely noticeable additional weight of the maxon drive of only 3.5 kilograms, in combination with the superior carbon technology from Thömus, delivers a ride that feels as natural on the trail as on the World Cup bike of overall World Cup winner Mathias Flückiger. As soon as you begin to climb, the Lightrider E Ultimate feels as if a tailwind is gently pushing you uphill, making it perfect for training or riding in a group. The unique freewheel technology of the maxon BIKEDRIVE AIR e-bike system ensures natural transitions from supported to non-supported riding and vice versa. The result is an e-bike with the perfect balance between weight and agility that feels just like a normal bike. The Lightrider E Ultimate is also available in an extra small frame size and is therefore suitable for everyone.

Maxon’s experience in the development of drive motors for Mars rovers over the course of its 60-year history is reflected in the system’s compact size, which allows the battery to be integrated invisibly into the frame. Only an inconspicuously integrated control element on the top tube hints at the extra power hidden in the bike. Equipped with a 250 Wh battery and an optional Range Extender with an additional 250 Wh capacity, technically challenging trails can be tackled with ease.

Thömus has been synonymous with high-tech bicycles from Switzerland for over 30 years. Olympic medalist Mathias Flückiger has been using the brand for four years. The geometry and kinematics of the new Lightrider E Ultimate are unique and were developed in collaboration with the top riders of the Thömus maxon Swiss Mountain Bike Racing Team. In World Cup racing events, the pros ride the Thömus Lightrider. The new e-bike is heavily based on this design and enables the team to train at higher frequencies without exceeding the optimal heart rate and performance range. “We can now have much longer training sessions and therefore work more intensely on improving our technique. The Lightrider E Ultimate has the potential to be a real game changer,” says Mathias Flückiger.

The new Lightrider E Ultimate with maxon drive is now available to preorder from Thömus, with prices starting at CHF 6,390.