Bosch Rexroth Wins Hermes Award 2023 with Smart Flex Effector

The Hermes Award 2023 goes to Bosch Rexroth. The award was presented at the opening ceremony of the Hannover Messe. On the photo from left to right: Dr. Jochen Köckler (Chairman of the Managing Board, Deutsche Messe AG), winners of Hermes Startup Awards, Thomas Donato (Member of the Executive Board responsible for the Factory Automation business at Bosch Rexroth AG), Dr. Ulf Lehmann (Head of the Linear Motion Technology Business Unit at Bosch Rexroth AG), Bettina Stark-Watzinger (Federal Minister for Education and Research). (Image source: Bosch Rexroth AG)

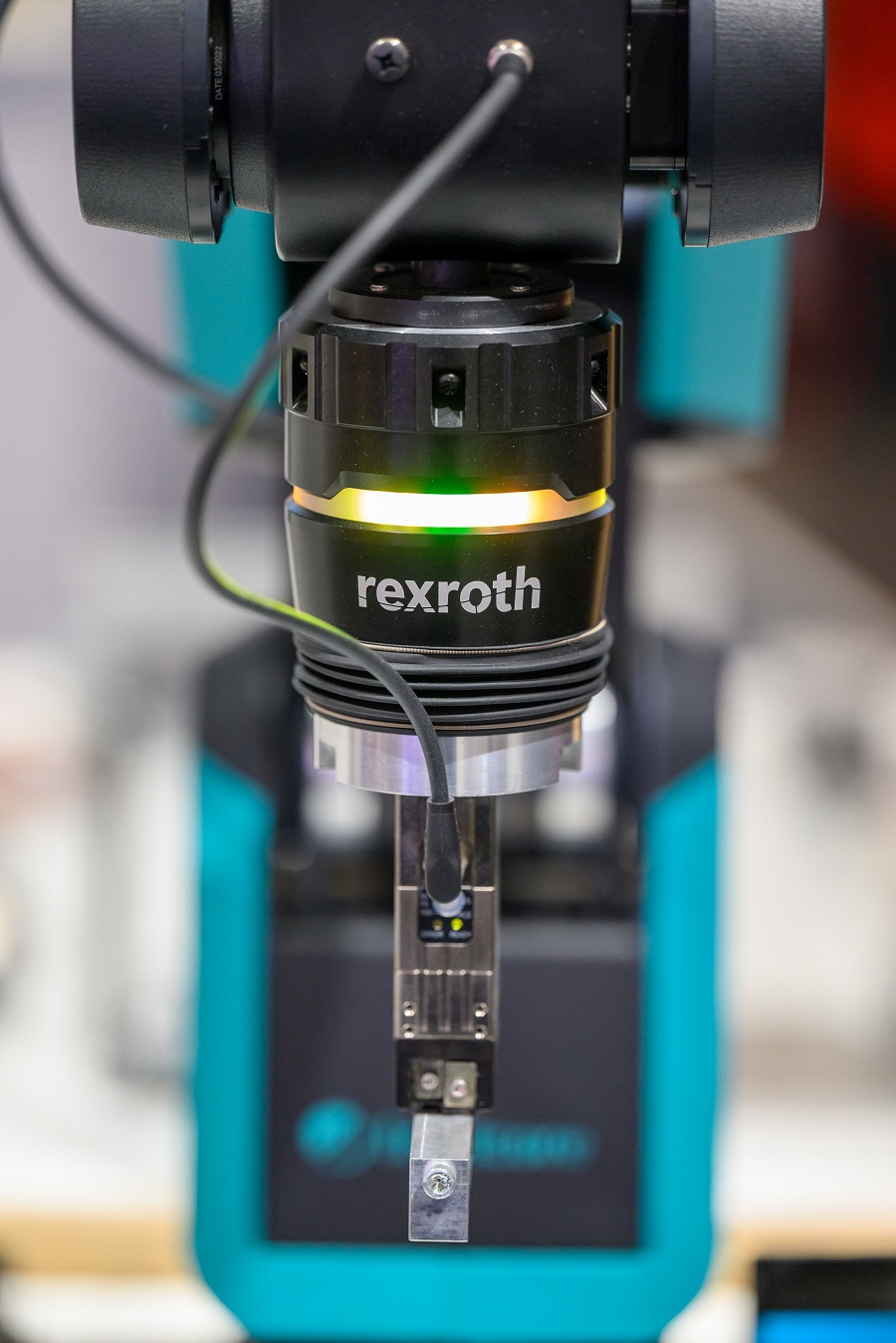

With the unique combination of a sensor system and kinematics working independently in six degrees of freedom, the Smart Flex Effector compensation module gives industrial robots a sense of touch similar to that of a human hand. It thus allows the automation of processes that were previously difficult to manage or could only be performed manually. The innovation was honored at Hannover Messe with the Hermes Award 2023, the most prestigious international industry prize. The Smart Flex Effector increases the range of applications for robots because it sensitively compensates for tolerances in real time. Users can thus automate joining process, complicated assembly movements or difficult handling tasks. The compensation module can also be retrofitted in existing robotic applications.

“Bosch Rexroth is shaping the future of automation by intelligently linking hardware and software,” said Thomas Donato, member of the executive board responsible for the Factory Automation business at Bosch Rexroth. “Through the interaction of sensors and software, industrial robots can relieve employees of repetitive or strenuous tasks.” Up until now, robots could only perform gripping and assembly tasks to a high-quality standard if the workpieces were always exactly at the programmed position. Even the slightest positional deviations resulted in errors because the usually rigid programming cannot sense and react flexibly.

The Smart Flex Effector is designed for use on robots such as articulated robots or Cartesian linear systems and is based on a kinematic system with six degrees of freedom. Via Sensitive Touch, sensors detect the exact position of the workpieces to be gripped and report the actual position in real time to the controller, which adapts the gripper's motion sequence to the specific position. As a result, the Smart Flex Effector can automatically compensate for tolerances when removing and positioning workpieces. This reduces the programming required, especially when handling different workpieces. In addition, employees without programming knowledge can also teach robots manually simply by moving the gripper into the correct position by hand. The Smart Flex Effector was developed in close cooperation between Bosch Research and Bosch Rexroth.

With the unique combination of a sensor system and kinematics working independently in six degrees of freedom, the Smart Flex Effector compensation module gives industrial robots a sense of touch similar to that of a human hand. (Image source: Martin Stollberg)

With the unique combination of a sensor system and kinematics working independently in six degrees of freedom, the Smart Flex Effector compensation module gives industrial robots a sense of touch similar to that of a human hand. (Image source: Martin Stollberg)The compensation module is so sensitive that it can safely handle even workpieces made from delicate materials such as glass. Because each movement is recorded as a data set and documented, the Smart Flex Effector improves process monitoring and quality. Based on the data, the control system or higher-level systems can detect troublesome deviations straight away. These are either corrected immediately or reported to the operating personnel. This prevents errors and avoids unnecessary costs owing to rejects or follow-up work.

The Smart Flex Effector can also be retrofitted into existing robots with little effort as it communicates with the relevant controllers via popular interfaces. It thus opens up numerous applications for which there were no economical automation solutions in the past.

The Smart Flex Effector allows the automation of processes that were previously difficult to manage or could only be performed manually. (Image source: Martin Stollberg)

The Smart Flex Effector allows the automation of processes that were previously difficult to manage or could only be performed manually. (Image source: Martin Stollberg)Bosch Rexroth is located in Hall 6, Stand D26 at Hannover Messe.