Ask the Expert

Gear Rating

THE QUESTION

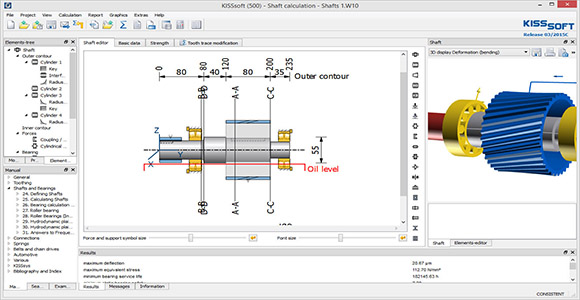

In order to realize meaningful savings using low-cost gear motors, some gear motor manufacturers are sizing the gears with safety for stress at single tooth contact SH min below 1,00; i.e. — minimal SH 0.82 — according to Calculation Method DIN 3990; Method B. Is this possible? Will the gear life be limited?

Expert response provided by Frank C. Uherek, principal engineer, Rexnord Gear.

Rating methods have safety factors based on flank (pitting) labeled as SH and root (bending) labeled as SF. They are computed as the ratio of the modified allowable stress number to the actual stress number. These values are a function of tooth geometry, method of manufacture, material, heat treatment, and application. If we assume an application factor KA of 1.0 based on the use of the product, a safety factor of 1.0 is based on 5 × 107 load cycles when pitting is not permitted. A value of SH less than 1.0 may be based on using some of the de-rate in power capacity caused by an application factor greater than 1.0 in the actual stress number calculation. Loading, application factor, number of load cycles, and minimum safety factors are subject to client/vendor agreement — as noted in the standard — and should be carefully reviewed to ensure the expected performance of the gear drive in the specific application.

A detailed review of the application and all factors used in the rating analysis would be required to determine the origin of the safety factor being less than 1.0 in this case.

Frank C. Uherek is

principal engineer/mill

products for Rexnord

Geared Products in

Milwaukee WI. In over 30

years he has held various

positions in design

engineering and quality

management, including enclosed drives, wind

turbine drives, and open gearing for mill and

kiln applications. He has served on numerous

AGMA technical committees, including as

vice chairman (and editor) of the Helical Gear

Rating Committee, and received the AGMA

TDEC award in 1997. In 2011, Uherek received

the AGMA Distinguished Service Award for

his work in developing AGMA gear rating

standards.

Frank C. Uherek is

principal engineer/mill

products for Rexnord

Geared Products in

Milwaukee WI. In over 30

years he has held various

positions in design

engineering and quality

management, including enclosed drives, wind

turbine drives, and open gearing for mill and

kiln applications. He has served on numerous

AGMA technical committees, including as

vice chairman (and editor) of the Helical Gear

Rating Committee, and received the AGMA

TDEC award in 1997. In 2011, Uherek received

the AGMA Distinguished Service Award for

his work in developing AGMA gear rating

standards.