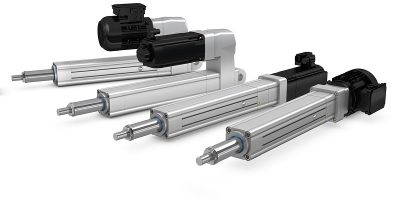

SKF Actuators Offer Modular Design for Speed, Load Capacity and Accuracy

SKF CASM-100 electromechanical actuators from SKF Motion Technologies, Inc. have been uniquely engineered with a modular design enabling tailored solutions for a wide range of industrial linear movement and positioning applications. Various modules providing choices among motor types, gearboxes, ball screws or roller screws, and accessories allow for custom combinations of components ideally suited for an application. Standardized interfaces connect the different components to each other for ideal operation of actuators in service.

These actuators deliver optimized performance in speed, load capacity, and positioning accuracy, perform virtually maintenance free and, compared with hydraulic or pneumatic systems, serve as more environmentally friendly and energy-efficient solutions. In addition, they use up to 80% less energy than pneumatic cylinders and 50% less energy than hydraulic alternatives and eliminate any need for constantly running compressors, hoses, and other components.

Applications include robotic cells, handling and packaging machines, sorting systems, manufacturing, and cutting and assembly machines, among many others across industries where reliable, accurate, and precise repetitive motion is required.

Featuring a linear design that can withstand even the harshest operating conditions, CASM-100 actuators are manufactured from high-grade materials, boast a long service life, and offer superior precision and repeatability. They can deliver a force range up to 82kN / 18,400 lbf, linear speeds up to 890 mm/s, long stroke lengths (up to 2 m / 6.5 ft.), and will support Industry 4.0 technology objectives.

CASM-100 actuators can fit standard industry footprints and can easily facilitate system retrofits or conversions to meet any space and performance requirements. Flexible mounting options and a variety of accessories are available. The actuators are fully equipped to achieve optimal service life, even at very high forces, and ultimately can deliver a highly favorable cost/performance ratio.